Zirconium-based alkylation catalyst and preparation method and application thereof

A technology of alkylation reagent and zirconium alkane, which is applied in the direction of catalyst activation/preparation, carbon compound catalyst, physical/chemical process catalyst, etc., can solve the problem of double-substituted alkyl anthracene easy to generate anthracene conversion rate, etc., and achieve easy recovery and recycling, high selectivity, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] According to a preferred embodiment of the present invention, the catalyst is composed of MOR carrier and highly dispersed zirconium obtained by complex modification with citric acid.

[0026] The second aspect of the present invention provides a method for preparing a highly dispersed zirconium-based catalyst, the method comprising:

[0027] (1) Disperse the zirconium salt and the modifying agent in water, stir, then add the carrier, and continue to stir under the magnetic force at room temperature, then evaporate the turbid liquid to remove excess water, and obtain the composite modified precursor after drying the obtained solid;

[0028] (2) Grinding, calcining and annealing the composite modified precursor to obtain a zirconium-based alkylation catalyst.

[0029] In the described composite modified precursor, relative to the carrier of 100 parts by weight, the total content of zirconium is 10-40 parts by weight, preferably 15-25 parts by weight, in terms of oxides; ...

Embodiment 1

[0042] The first step of catalyst preparation: 3.1g of zirconium nitrate pentahydrate and 1.65g of citric acid were added to 60mL of deionized water at room temperature, stirred, and then 4g of MOR molecular sieves were added. Stirring was continued for 2 hours, and then the water was evaporated at 80°C, dried at 100°C for 24 hours, ground, and calcined at 500°C for 10 hours to prepare a citric acid-modified 18wt% Zr-MOR molecular sieve catalyst.

[0043] The second step of catalytic alkylation reaction: take the Zr-MOR molecular sieve catalyst (50wt%, 1.0g) and anthracene (2.0g) obtained in the first step, add 12mL3,4-dichlorobenzotrifluoride as a solvent, and then add tert-amyl Alcohol (1.1eq, 1.1g) was used as an alkylating agent. Stir at room temperature to fully mix and activate. The initial pressure was 2.0MPa, and then the temperature was programmed to rise to 170°C. The total reaction time was 4h. According to gas phase analysis, the selectivity of 2-tert-amylanthracen...

Embodiment 2

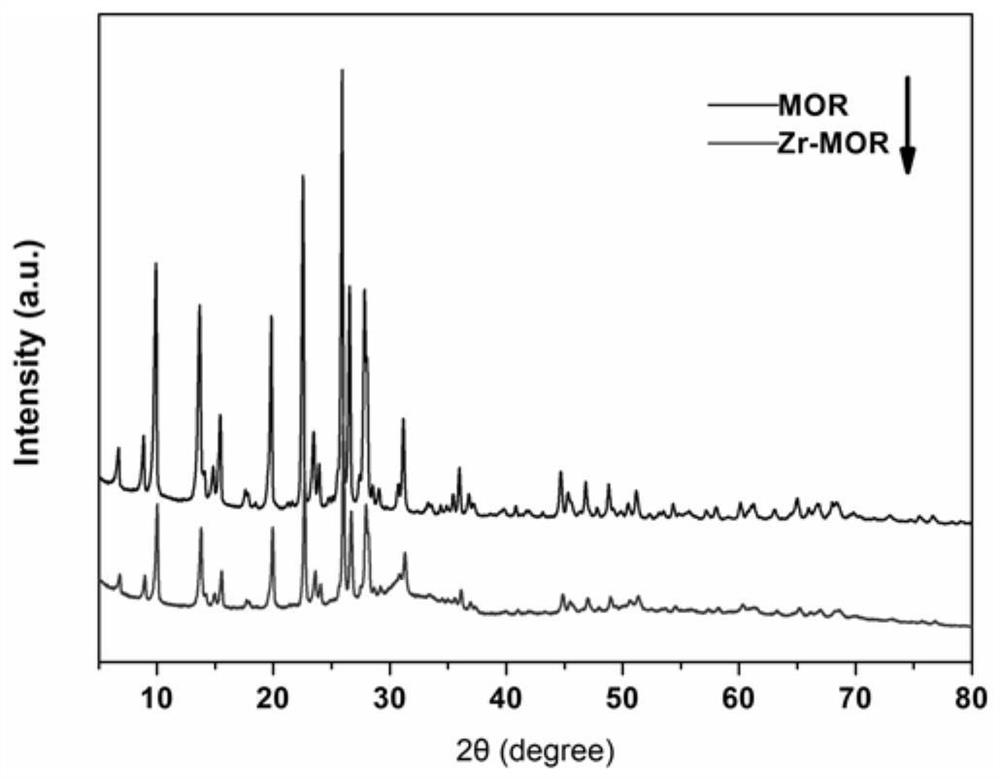

[0051] The first step of catalyst preparation: 4.12g of zirconium nitrate pentahydrate and 2.22g of citric acid were added to 60mL of deionized water at room temperature, stirred, and then 4g of MOR molecular sieves were added. Continue to stir for 2h, then evaporate the water at 80°C, dry at 100°C for 24h, grind, and calcine at 500°C for 10h to prepare a 22wt% Zr-MOR molecular sieve catalyst modified by citric acid. The X-ray single crystal diffraction pattern is shown in figure 1 .

[0052] The second step of catalytic alkylation reaction: take the Zr-MOR molecular sieve catalyst (30wt%, 0.6g) and anthracene (2.0g) obtained in the first step, add 12mL3,4-dichlorobenzotrifluoride as a solvent, and then add tert-amyl Alcohol (1.1eq, 1.1g) was used as an alkylating agent. Stir at room temperature to fully mix and activate. The initial pressure was 2.0MPa, and then the temperature was programmed to rise to 170°C. The total reaction time was 4h. According to gas phase analysis, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com