Preparation method of gallocatechin gallate

A technology of gallocatechin and gallic acid ester, applied in the field of medicine and chemical industry, can solve the problems of poor environment and product quality, inconvenient operation and application, complicated operation steps, etc., achieve low reaction conversion efficiency, reduce risk factor, and process The effect of cycle shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 50g of EGCG powder as a raw material, add 2500ml of 0.001mol / L hydrochloric acid solution to dissolve, gradually heat to 100°C, stir and react for 16 hours, stop heating and cool to room temperature, add 0.001mol / L sodium hydroxide solution to adjust the pH to near Neutral to obtain the post-reaction solution; gradually add the post-reaction solution to the chromatographic column equipped with PS-DVB microspheres that have been treated (the particle size range of the microspheres is 100-200um, and the column volume is 2500ml), and then Elute with 5% ethanol solution until there is no obvious GCG outflow, receive the eluent according to the outflow of every 0.5 column volume, detect and select the eluent containing the target component by thin layer, concentrate and remove alcohol, and place it for crystallization. That is, 16.2 g of white powder was obtained.

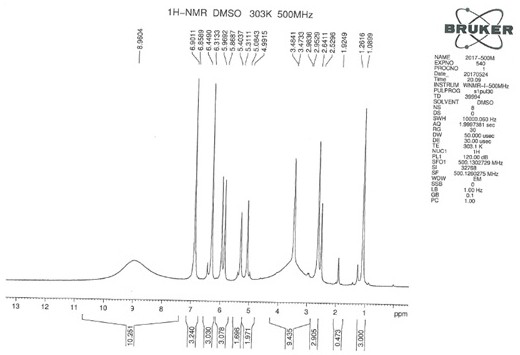

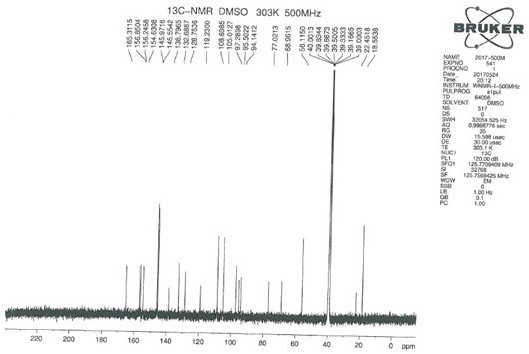

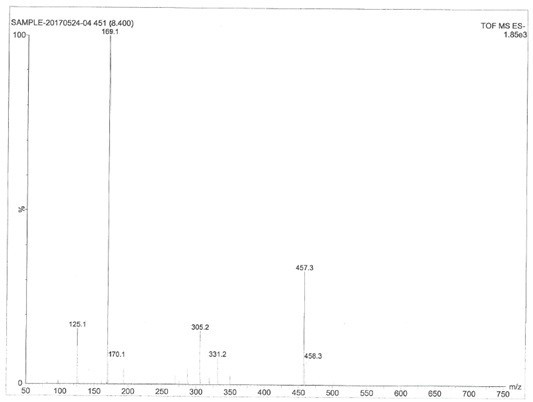

[0032] After identification, the white powder obtained in this example was determined to be GCG (gallocat...

Embodiment 2

[0034] Take 50g of EGCG powder as a raw material, add 100ml of 0.1mol / L acetic acid solution to dissolve, gradually heat to 60°C, stir and react for 4 hours, stop heating and cool to room temperature, add 0.1mol / L sodium hydroxide solution to adjust the pH to near Neutral to obtain the post-reaction solution; gradually add the post-reaction solution into the chromatographic column that has been treated with PS-DVB microspheres (the particle size range of the microspheres is 20-40um, and the column volume is 250ml), and then Use 5% methanol solution to elute until there is no obvious GCG outflow, receive the eluent according to the outflow of every 0.5 column volume, perform thin-layer detection and select the eluent containing the target component, concentrate and remove alcohol, and place it for crystallization. That is, 24.1 g of gallocatechin gallate white powder was obtained, and its purity was 96.0% as detected by HPLC.

Embodiment 3

[0036] Take 50g of EGCG powder as a raw material, add 500ml of 0.01mol / L phosphoric acid solution to dissolve, gradually heat to 80°C, stir and react for 10 hours, stop heating and cool to room temperature, add 0.01mol / L sodium hydroxide solution to adjust the pH to near Neutral to obtain the post-reaction solution; gradually add the post-reaction solution into the chromatographic column equipped with PS-DVB microspheres that have been treated (the particle size range of the microspheres is 60-100um, and the column volume is 500ml), and then Use 30% ethanol solution to elute until there is no obvious GCG outflow, receive the eluent according to the outflow of every 0.5 column volume, perform TLC detection and select the eluent containing the target component, concentrate and remove alcohol, and place it for crystallization. That is, 15.9 g of gallocatechin gallate white powder was obtained, and its purity was 95.8% as detected by HPLC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com