Method for preparing liquefied petroleum gas by a two-step method

A technology of liquefied petroleum gas and step method, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problem that the output cannot meet the time requirement, and achieve the effect of suppressing the formation of carbon deposits, improving the stability, and optimizing the reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Next, further description will be made in conjunction with the accompanying drawings and specific embodiments:

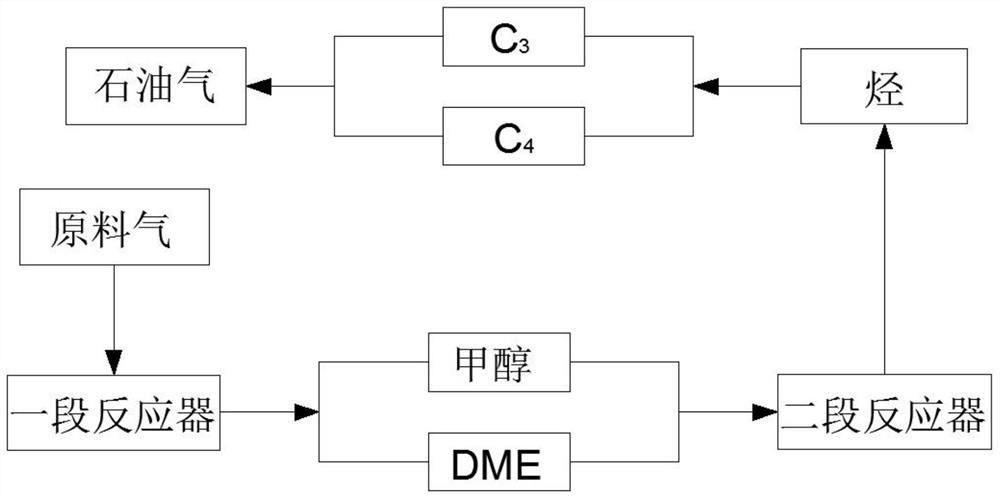

[0021] See Figure 1-2 , A method of preparing liquefied petroleum gas according to an embodiment of the present invention, including:

[0022] (1) The first step of reaction: The syngas is converted into methanol and DMF in a reactor with a syngas as a raw material.

[0023] (2) Second step reaction: The methanol and DME obtained by step (1) are converted into hydrocarbons in the segment reactor, and the main component is C. 3 And C 4, That is, liquefied petroleum gas.

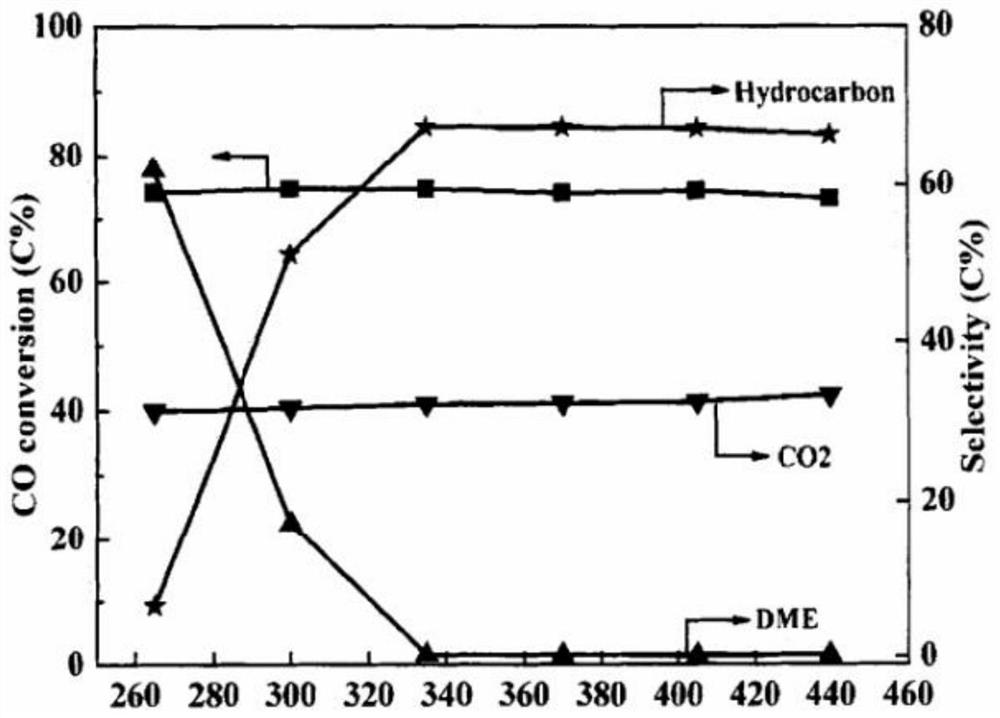

[0024] The method of preparing liquefied petroleum gas according to claim 1, wherein the methanol is formed in a reactor and converted to DME, methanol dewatering under the action of dehydration. DME. It can be carried out at a temperature below 250 ° C, so that the sintering of the Cu in the methanol synthesis catalyst can be slowed while ensuring the CO conversion.

[0025] The method of prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com