Graphene-high-entropy alloy composite coating and preparation method thereof

A high-entropy alloy and composite coating technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of water-cooled wall failure and short service life of water-cooled wall, and achieve heat source energy concentration and good The effect of high temperature oxidation corrosion resistance and good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

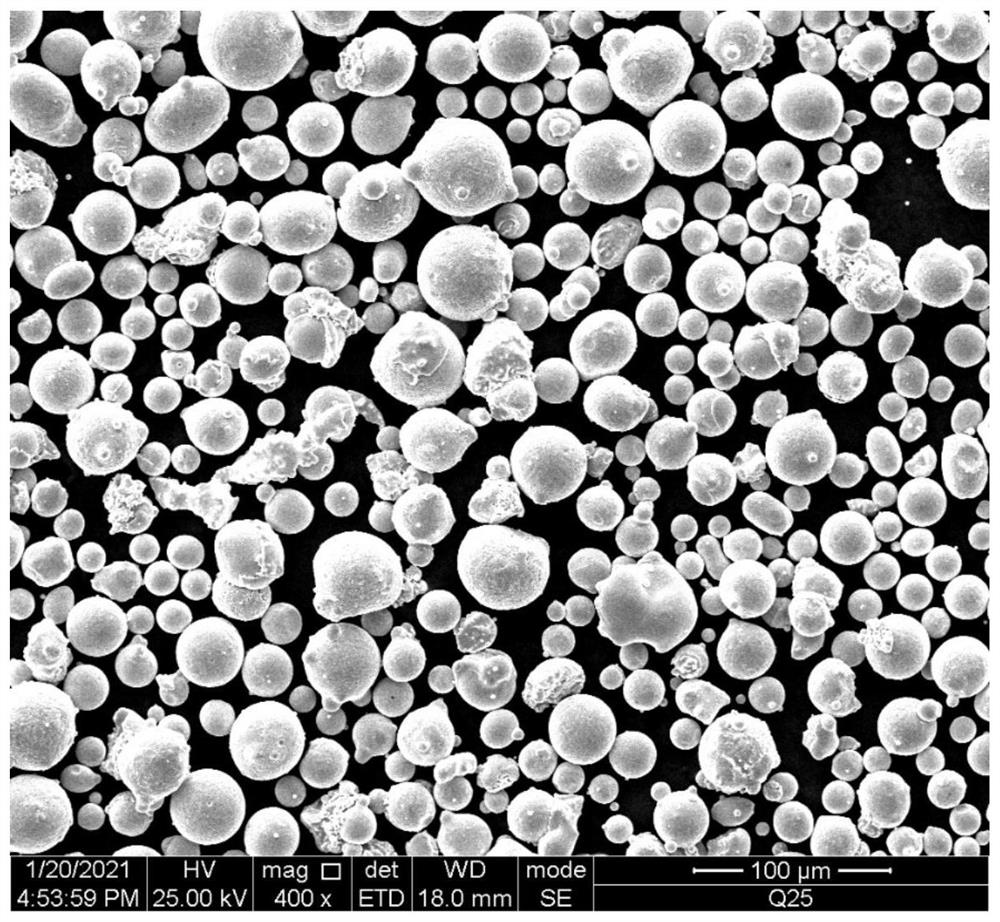

[0031] (1) According to the molar ratio of 1:2:1:1:2, respectively weigh Co, Cr, Ni, Fe, Cu powders with a particle size range of about 30-50 μm, mix them and put them into a ball mill jar for mechanical alloying change;

[0032] The milling parameter is 300rpm, stop for 10min every 30min, and control the milling time at 60h;

[0033] (2) In the high-entropy alloy powder that completes mechanical alloying, add the graphene that quality is 2% of high-entropy alloy powder and mix, add the dehydrated alcohol of 500mL in every 100g mixed powder, carry out ultrasonic dispersion 5h, then in Vacuum drying at 100°C for 15 hours to obtain GN-CoCr 2 NiFeCu 2 mixed powder;

[0034] Graphene thickness is 3-8nm, particle size is 5-50μm;

[0035] (3) Sandblasting the metal substrate 20 steel and cleaning it;

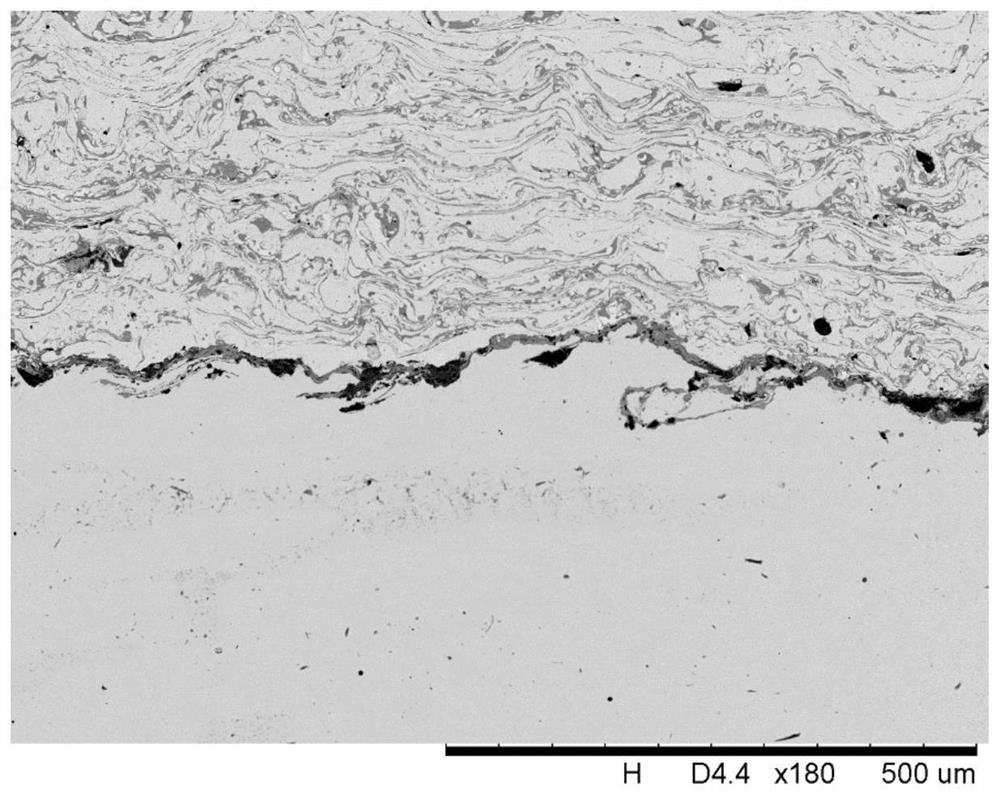

[0036] Use plasma spraying equipment to spray on the substrate to get GN-CoCr 2 NiFeCu 2 Composite coating;

[0037] Spraying parameters are power 30kW, voltage 60V, current 5...

Embodiment 2

[0042] (1) According to the molar ratio of 1:1:1:1:2, respectively weigh Co, Cr, Ni, Fe, Cu powders with a particle size range of 30-40 μm, mix them and put them into a ball mill jar for mechanical alloying ;

[0043] The ball milling parameters are 400rpm speed, 10 minutes stop every 60 minutes of ball milling, and the ball milling time is controlled at 60h;

[0044](2) In the high-entropy alloy powder that has been mechanically alloyed, add graphene with a mass of 1% of the alloy powder and mix, add 450mL of absolute ethanol to every 100g of mixed powder, perform ultrasonic dispersion for 5h, and then heat the mixture at 100°C Dry under vacuum for 15h to get GN-CoCrNiFeCu 2 mixed powder;

[0045] Graphene thickness is 3-8nm, particle size is 5-50μm;

[0046] (3) Sandblasting the metal substrate 20 steel and cleaning it;

[0047] Use plasma spray equipment to spray on the substrate to get GN-CoCrNiFeCu 2 Composite coating;

[0048] The spraying parameters are power 25kW...

Embodiment 3

[0050] (1) According to the molar ratio of 1:1:1:1:1, respectively weigh Co, Cr, Ni, Fe, Cu powders with a particle size range of 30-40 μm, mix them and put them into a ball mill jar for mechanical alloying ;

[0051] The ball milling parameters are 350rpm rotating speed, every 45 minutes of ball milling, stop for 10 minutes, and the ball milling time is controlled at 60h;

[0052] (2) Add 3% graphene with a mass of 3% of the alloy powder to the mechanically alloyed high-entropy alloy powder, add 500 mL of absolute ethanol to every 100 g of the mixed powder, perform ultrasonic dispersion for 5 hours, and then heat Dry under vacuum for 15 hours to obtain GN-CoCrNiFeCu mixed powder;

[0053] Graphene thickness is 3-8nm, particle size is 5-50μm;

[0054] (3) Sandblasting the metal substrate 20 steel and cleaning it;

[0055] Use plasma spraying equipment to spray on the substrate to obtain GN-CoCrNiFeCu composite coating;

[0056] Spraying parameters are power 35kW, voltage 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com