IGCC power station coupling water electrolysis equipment system and operation method thereof

An electrolysis equipment, water electrolysis technology, applied in the electrolysis process, electrolysis components, electrical components, etc., can solve the problems of the inability to realize the IGCC power station to respond to power grid frequency regulation, and the complex composition of the air separation system, so as to increase the operating efficiency and improve the gas production rate. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

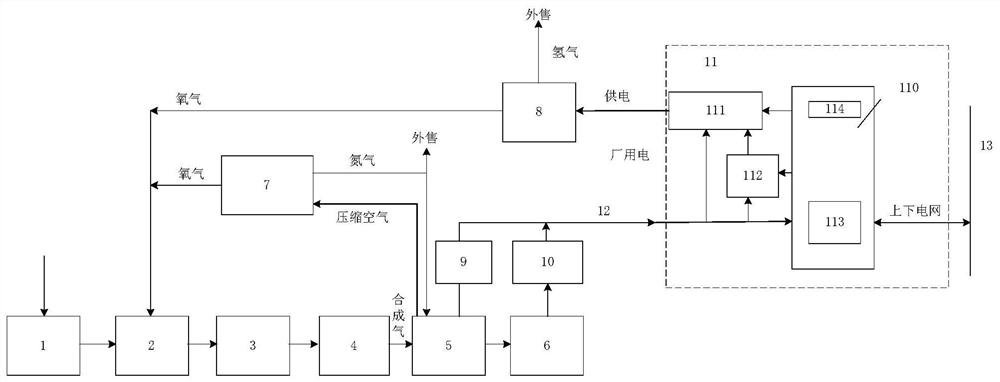

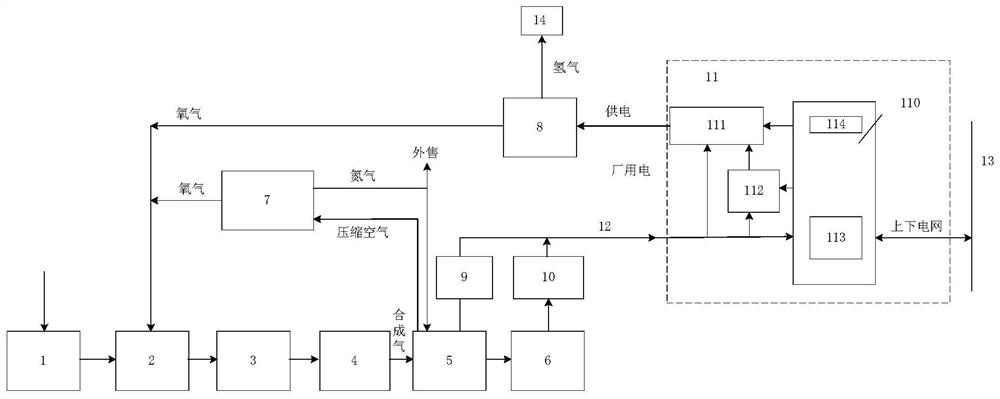

[0050] Embodiment 1: An IGCC power station coupling water electrolysis equipment system, including IGCC power station conventional equipment: coal pretreatment device 1, coal gasification furnace 2, air separation device 7, gas turbine 5, waste heat boiler 6, gas turbine generator 9, steam turbine generator 10 and power transmission module 11,

[0051] It also includes water electrolysis equipment 8 and its power supply line, oxygen supply pipeline, hydrogen supply pipeline, hydrogen storage tank and oxygen storage tank. The power supply line of the water electrolysis equipment is connected to the IGCC power station electric energy output terminal and the grid. The electricity generated by the IGCC power station or the electricity delivered by the power grid is electrolyzed to produce hydrogen and oxygen; the oxygen supply pipeline of the water electrolysis equipment is connected to the oxygen supply pipeline of the coal gasifier, and the oxygen produced by the water electrolys...

Embodiment 2

[0053] The system of the present invention is also provided with a peak regulation and frequency regulation control module, the peak regulation and frequency regulation control module is connected to the control terminal of the electric energy output of the IGCC power station, and the peak regulation and frequency regulation control module controls the increase of the electric load power delivered by the generator to the water electrolysis equipment Or reduce, in response to the grid's peak and frequency regulation load demand for IGCC power plants.

Embodiment 3

[0055] The power supply line of the water electrolysis equipment 8 is connected to the power output terminal of the IGCC power station, the power grid, the plant power supply and the step-up transformer through the power transmission and transformation and power supply module 111, that is, the power source of the water electrolysis equipment 8 has a generator outlet bus 12 Any one or combination of power supply, plant power supply, main step-up transformer power supply, and power grid off-grid power supply; it is conducive to improving the continuous reliability of the working power supply of water electrolysis equipment, and can also absorb abundant electric energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com