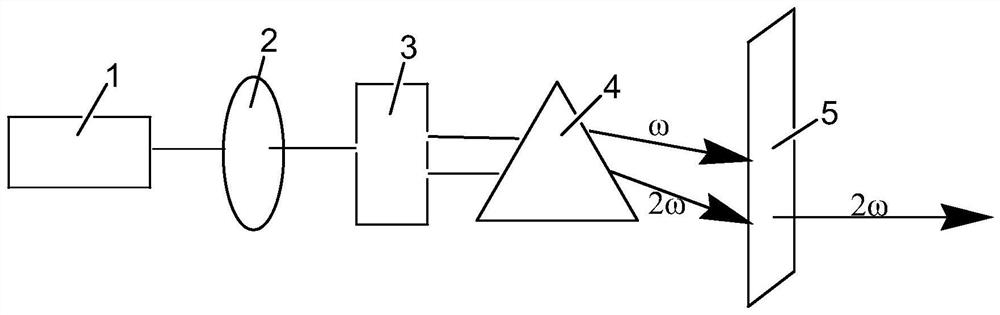

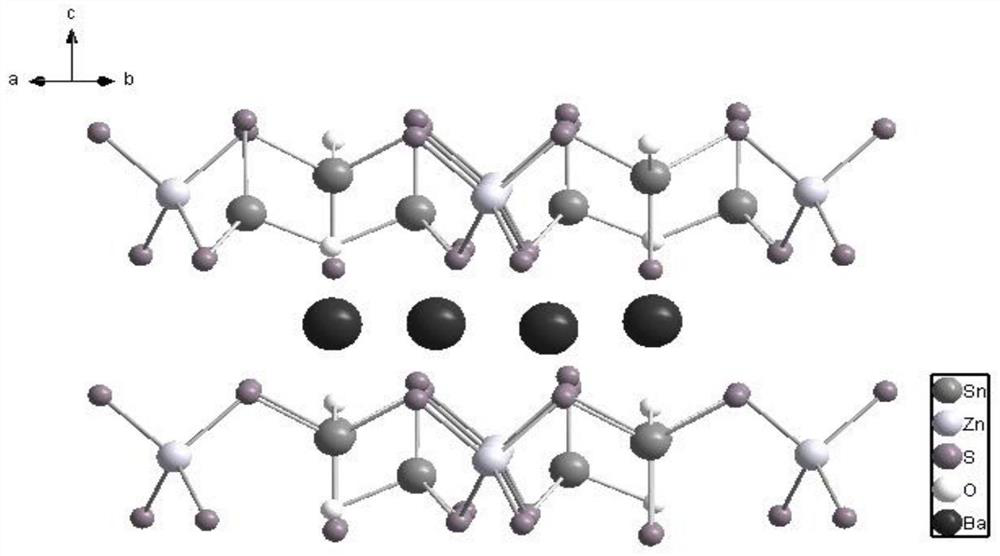

Barium-zinc-tin-sulfur-oxygen compound, barium-zinc-tin-sulfur-oxygen nonlinear optical crystal, preparation method and application

A tin-sulfur-oxygen nonlinear compound technology, applied in the field of nonlinear optical devices, can solve problems such as limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

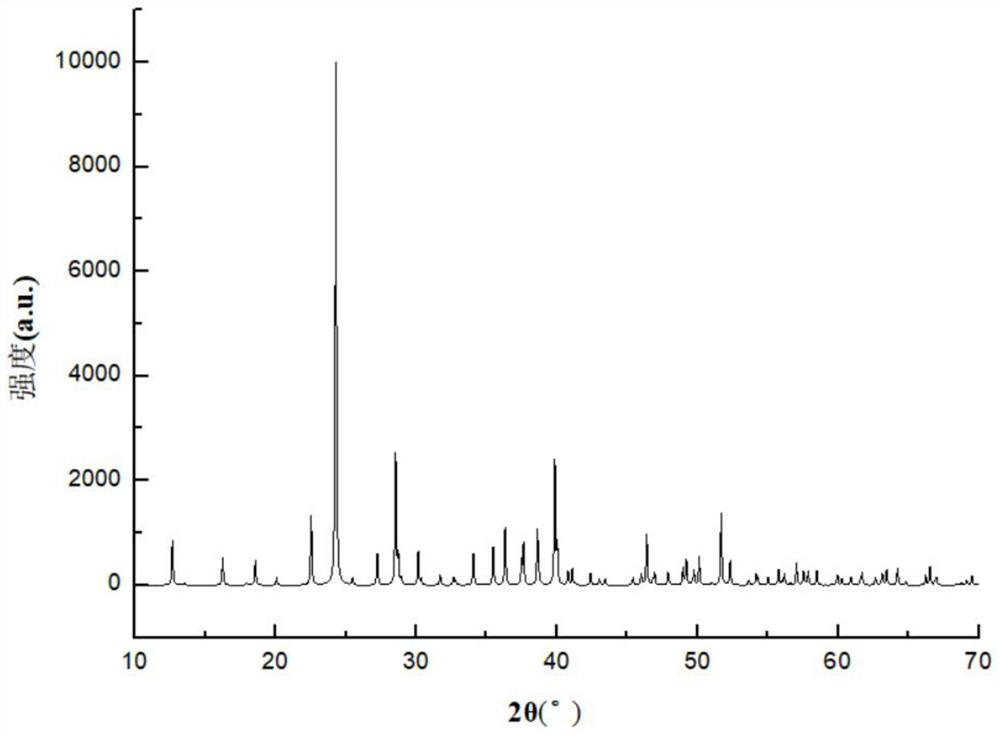

[0047] According to the reaction formula: 2Ba+1ZnO+2Sn+6S→Ba 2 ZnSn 2 S 6 O preparation compound barium zinc tin sulfur oxide polycrystalline powder:

[0048] a. Mix barium element, zinc oxide powder, tin element and sulfur powder in a molar ratio of 2:1:2:6 in a glove box filled with inert gas argon in an airtight container with a water content and an oxygen content of 0.05ppm After uniformity, put it into a clean graphite crucible, put it into a quartz glass tube, and place the quartz tube containing the raw material in a vacuum of 10 -3 Sealed after vacuuming under the condition of Pa;

[0049] b. The quartz tube sealed in step a is raised from room temperature to 130°C at a temperature increase rate of 10°C / h, kept for 30 hours, and then heated to 750°C at a temperature of 20°C / h, and kept for 70 hours;

[0050] c. Cool down to room temperature at a rate of 2°C / h, take out the sample, put it in a mortar, grind it, and grind it to get the white compound Ba 2 ZnSn 2 S ...

Embodiment 2

[0056] According to the reaction formula: 1BaO+1Ba+2Zn+2Sn+6S→Ba 2 ZnSn 2 S 6 O preparation compound barium zinc tin sulfur oxide polycrystalline powder:

[0057] a. In an airtight container with a water content and an oxygen content of 0.05ppm, the barium element, barium oxide, zinc element, tin element and sulfur powder are in a molar ratio of 1:1:2 in a glove box filled with inert gas argon: 2:6 mixed evenly, put it into a clean graphite crucible, put it into a quartz glass tube, put the quartz tube containing the raw material in a vacuum of 10 -3 Sealed after vacuuming under the condition of Pa;

[0058] b. The quartz tube sealed in step a is raised from room temperature to 200°C at a heating rate of 40°C / h, and kept at a temperature of 60 hours, then raised to 800°C at a temperature of 20°C / h, and kept at a temperature of 90 hours;

[0059] c. Cool down to room temperature at a rate of 5°C / h, take out the sample and put it into a mortar, crush it, and grind it to obta...

Embodiment 3

[0065] According to the reaction formula: 1BaO+1Ba+2Zn+2SnS 2 +2S→Ba 2 ZnSn 2 S 6 O preparation compound barium zinc tin sulfur oxide polycrystalline powder:

[0066] a. In a glove box filled with an inert gas argon in an airtight container with a water content and an oxygen content of 0.05ppm, the barium element, barium oxide, zinc element, tin disulfide and sulfur powder are mixed in a molar ratio of 1:1:2 :2:2 After mixing evenly, put it into a clean graphite crucible, put it into a quartz glass tube, and place the quartz tube with raw materials at a vacuum of 10 -3 Sealed after vacuuming under the condition of Pa;

[0067] b. The quartz tube sealed in step a is raised from room temperature to 300°C at a heating rate of 40°C / h, and kept for 60 hours, then raised to 780°C at a temperature of 10°C / h, and kept for 100 hours;

[0068] c. Cool down to room temperature at a rate of 3°C / h, take out the sample and put it in a mortar, crush it, and grind it to obtain the white ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com