A kind of wild tussah silk brushed yarn and preparation method thereof

A tussah silk and wool yarn technology, applied in the field of napped yarn, can solve the problems of poor anti-wrinkle performance of tussah silk fabrics, poor anti-wrinkle performance of fabrics, and difficult dyeing of tussah silk, and achieve antistatic treatment, tensile performance and anti-wrinkle performance. , Improve the effect of dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

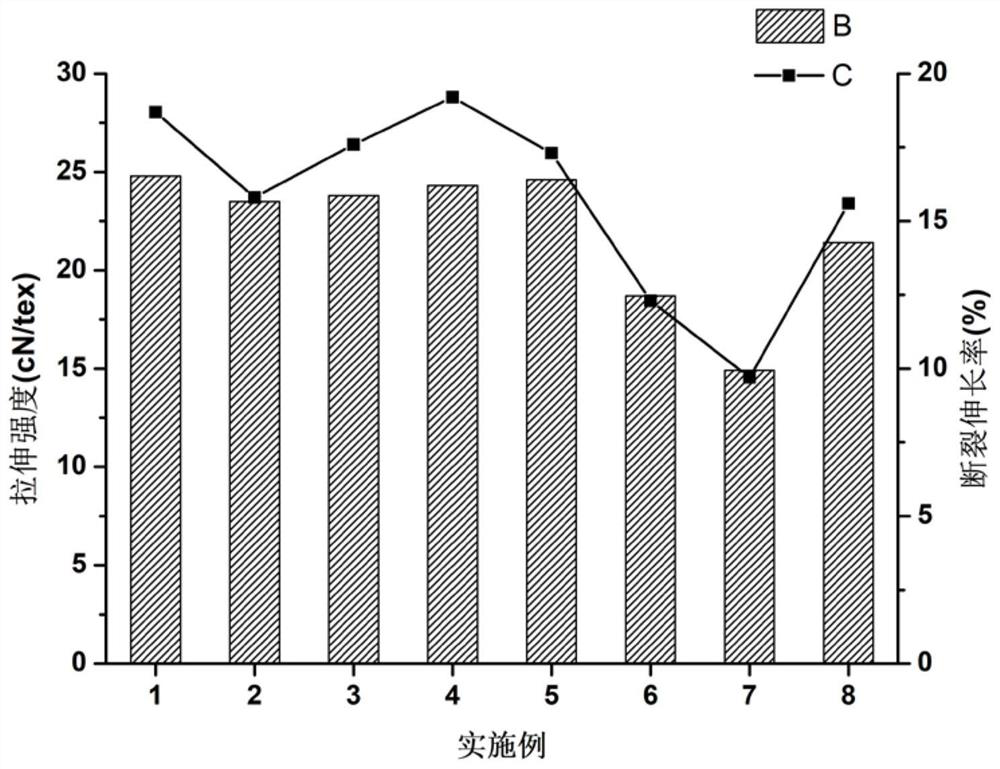

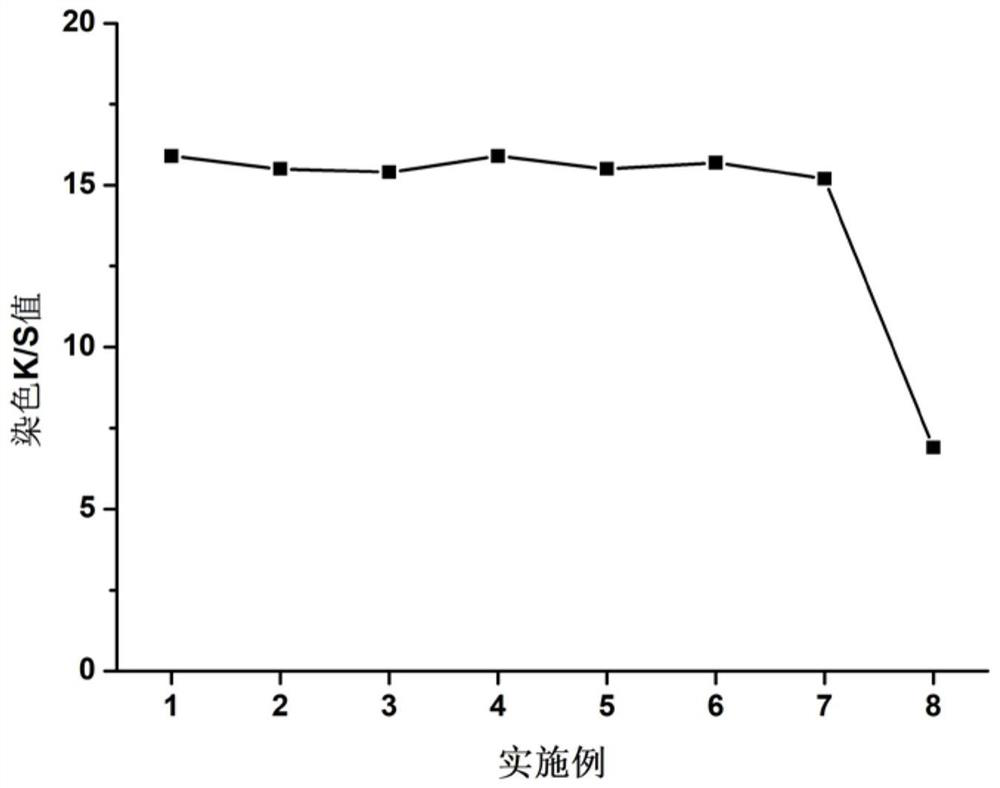

Examples

Embodiment 1

[0076] Embodiment 1: a kind of wild tussah silk brushed yarn:

[0077] The present embodiment provides a kind of wild tussah silk brushed yarn, including:

[0078] Core yarn: 40D nylon filament, the core yarn content is 13%;

[0079] Decorative yarn: tussah silk / basolan wool blended roving with a blending ratio of 50:50, the average fineness of the basolan wool is 22.5μm, the average length is 78mm, and the decorative yarn content is 85%;

[0080] Fixed yarn: 40D nylon filament, the fixed yarn content is 2%.

[0081] Wild tussah silk drawing yarn is prepared by the following method:

[0082] 1) Dyeing treatment:

[0083] 1.1) Basulan wool dyeing: Soak Basulan wool in hexamethylenediamine solution with a concentration of 2g / L for 30min, rinse with deionized water, and set aside for use; 4g reactive red L-S, 1g sodium acetate, 1g Polyoxyethylene fatty alcohol ether was added to 1L of deionized water, ultrasonically dispersed for 20min, added with 25g of copper nitrate, stirr...

Embodiment 2

[0101] Embodiment 2: Another kind of wild tussah silk brushed yarn:

[0102] This embodiment provides another kind of wild tussah silk brushed yarn. The amount of ethylene oxide added is 36g and 22g respectively, and the molar ratio of polyoxyethylene ether and hydroxypropyl methacrylate in the obtained polyoxyethylene ether-hydroxypropyl methacrylate block copolymer is 1:0.5 .

Embodiment 3

[0103] Embodiment 3: another kind of wild tussah silk brushed yarn:

[0104] This embodiment provides another kind of wild tussah silk brushed yarn. The addition of ethylene oxide is respectively 43.2g, 22g, and in the obtained polyoxyethylene ether-hydroxypropyl methacrylate block copolymer, the mol ratio of polyoxyethylene ether and hydroxypropyl methacrylate is 1: 0.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com