Loach feed for improving disease resistance

A technology for loach feed and disease resistance, which is applied in the field of loach feed for improving disease resistance, can solve the problems that the specifications of feed raw materials do not meet the needs of use, the feed is inconvenient to store, and the quality of the feed is poor, so as to speed up the time to market and meet the requirements of the market. Size, attractive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A loach feed for improving disease resistance, comprising the following raw materials in parts by weight: 17 parts of flour, 14 parts of fish meal, 7 parts of shrimp shell powder, 8 parts of peeled and expanded soybean meal, 7 parts of cotton meal, 6 parts of potato flour, and 11 parts of rice bran , 4 parts of astragalus powder, 2 parts of hemoglobin powder, 1 part of soybean oil, 0.7 part of choline chloride, 1.5 parts of montmorillonite, 2 parts of distiller's grains, 0.7 part of multivitamin and 0.2 part of compound trace element, wherein, the compound Vitamins are formed by mixing vitamin A, vitamin B, vitamin C, and vitamin E in a weight ratio of 1:1:1.8:2.2, and the composite trace elements are composed of ferrous sulfate, manganese sulfate, zinc oxide, copper sulfate, calcium iodate and 1:0.8:1.3:0.7 weight ratio mixed to form.

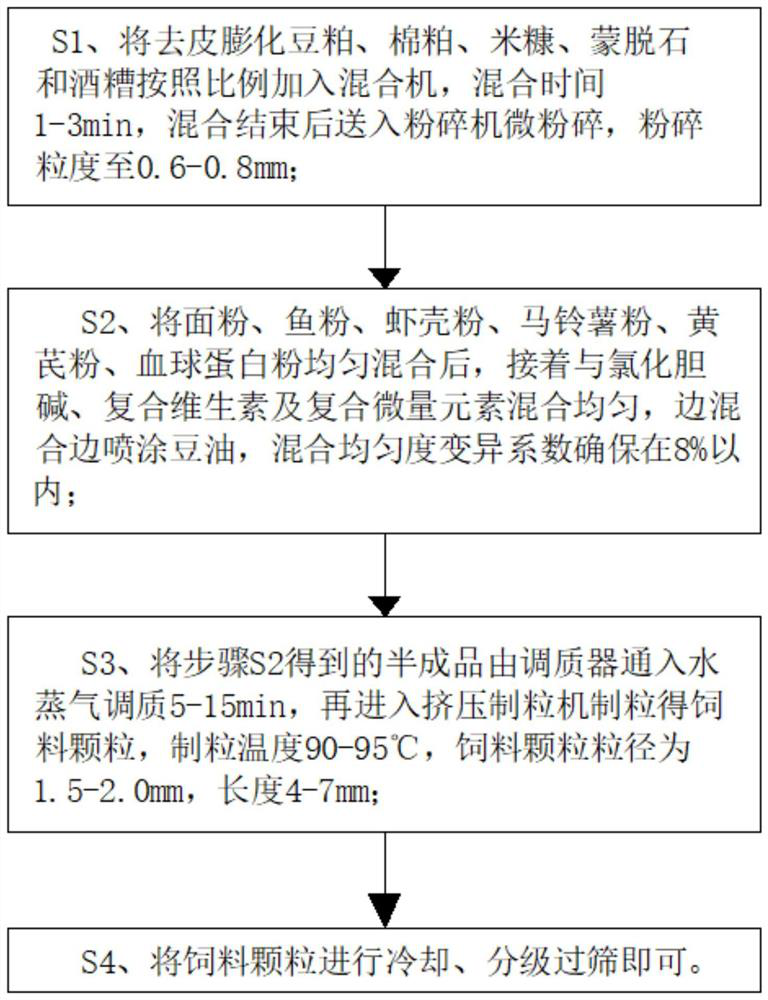

[0052] A kind of preparation technology of loach feed that improves disease resistance, such as figure 1 shown, including the followi...

Embodiment 2

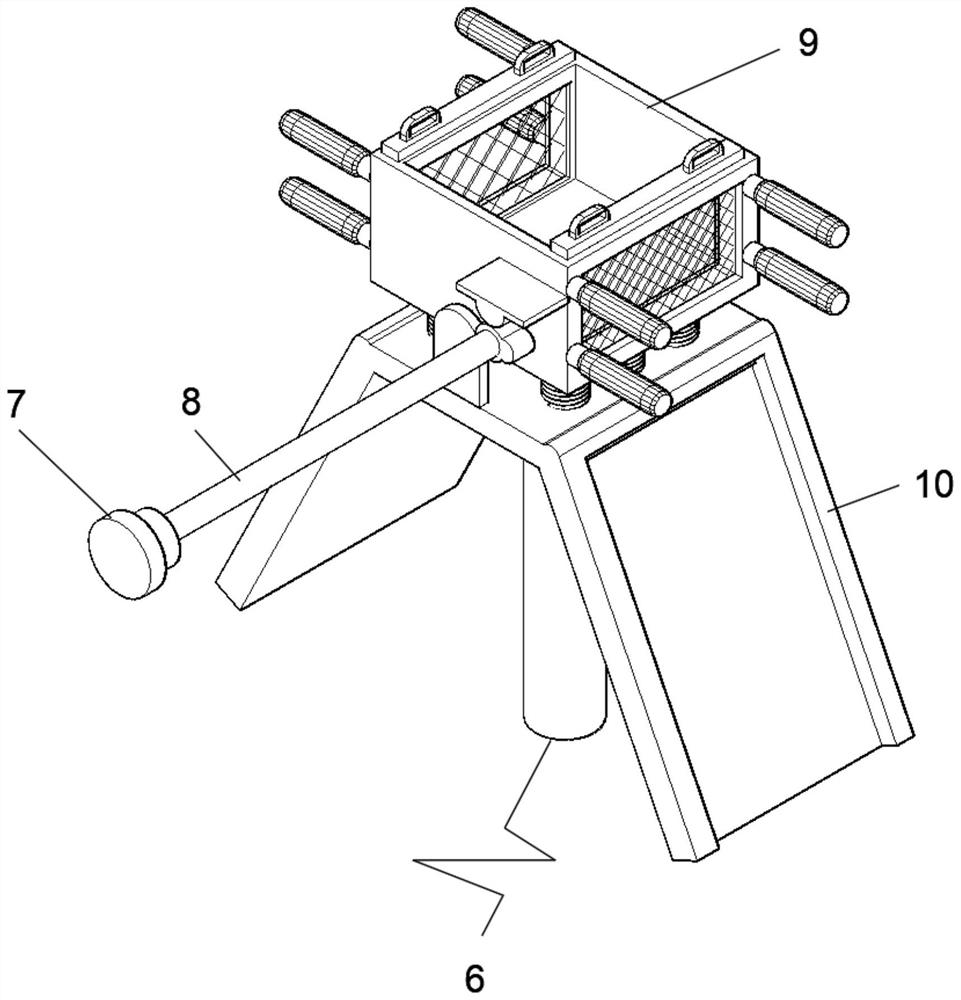

[0069] On the basis of Example 1, such as Figure 12 As shown, the middle part of the conveying and discharging plate 36 is provided with a conveying groove, and the conveying groove is conically arranged, and the width of the outermost end of the conveying groove is 10 cm.

[0070] When implementing this embodiment, since the middle part of the conveying and discharging plate 36 is provided with a conveying trough, and the conveying trough is tapered, and the width of the outermost end of the conveying trough is 10 cm, so the material body discharged from the conveying trough can be more easily Concentration, so as to facilitate the collection and processing of the material body discharged from the support net 38, and it is not easy to spill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com