Anti-allergy polishing paste containing potassium calcium phosphosilicate bioglass

A bio-glass, potassium phosphosilicate technology, applied in the field of dental polishing, can solve the problems of dental fluorosis and skeletal fluorosis, the anti-sensitivity effect is not long-lasting, toxic and side effects, etc., to inhibit bacteria, whitening effect and taste improvement, Effects without toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0040] Preparation example 1 provides a kind of potassium calcium phosphosilicate bioglass, and its preparation steps are:

[0041] Mix 50g of nano-silica, 20g of potassium dihydrogen phosphate, 10g of potassium carbonate and 30g of calcium oxide, stir evenly and put them into a high-temperature melting furnace, heat to 1550°C for a high-temperature liquid-phase chemical reaction for 6 hours to obtain potassium calcium phosphosilicate, Calcium potassium phosphosilicate is cooled to 25°C, and then the cooled calcium calcium phosphosilicate is pulverized into 5 μm particles using an ultrafine pulverizer to obtain calcium calcium phosphosilicate bioglass;

[0042] The chemical reaction formula of the synthesis of potassium calcium phosphosilicate by described nano silicon dioxide, potassium dihydrogen phosphate, potassium carbonate and calcium oxide is:

[0043] SiO 2 +KH 2 PO 4 +K 2 CO 3 +CaO=KCaPSiO 6 +CO 2 ↑+K 2 O↑+H 2 O↑;

[0044] Wherein, the high-temperature melti...

Embodiment 1

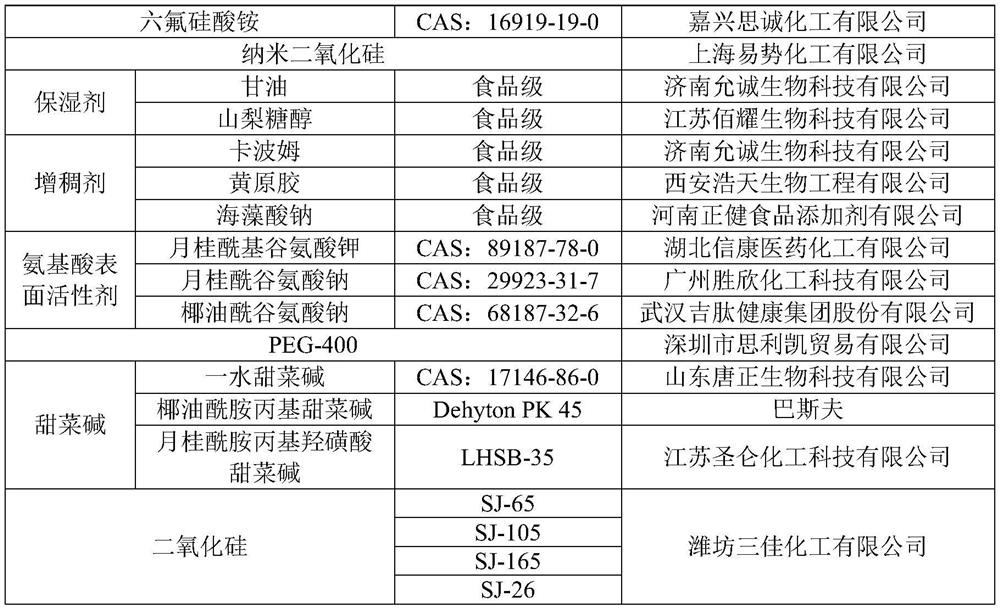

[0048] Embodiments 1-26 provide an anti-sensitivity polishing paste containing calcium calcium phosphosilicate bioglass, which will be described below by taking Embodiment 1 as an example.

[0049] The anti-sensitive polishing paste containing calcium calcium phosphosilicate bioglass that embodiment 1 provides, its preparation steps are:

[0050] Stir 30g humectant, 2g thickener, 3g amino acid surfactant and 2g betaine evenly, then add 2.5g calcium calcium phosphosilicate bioglass and 5g silicon dioxide, stir, grind and knead until fully mixed , and then evacuated until the vacuum degree reaches 0.096MPa, and finally aged for 180min to obtain an anti-sensitive polishing paste containing calcium calcium phosphosilicate bioglass;

[0051] Wherein, the humectant is food grade glycerin;

[0052] Described thickening agent is food grade carbomer;

[0053] The amino acid surfactant is sodium cocoyl glutamate (CAS No. 68187-32-6);

[0054] The betaine is betaine monohydrate (CAS N...

Embodiment 2-5

[0057] Examples 2-5 are the same as Example 1, except that the quality of the raw materials for the preparation of the anti-sensitive polishing paste containing calcium calcium phosphosilicate bioglass is different in quality, see Table 2 for details.

[0058] Table 2

[0059] components Example 1 Example 2 Example 3 Example 4 Example 5 moisturizer 30g 50g 40g 40g 40g thickener 2g 4g 3g 3g 3g amino acid surfactant 3g 5g 4g 4g 4g betaine 2g 4g 3g 3g 3g Potassium calcium phosphosilicate bioglass 2.5g 7.5g 5g 4g 5g silica 5g 15g 10g 8g 12g

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com