Graphdiyne composite filtering membrane as well as preparation method and application thereof

A composite filtration and graphdiyne technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low loading rate, improper arrangement, poor distributability, etc., and achieve low energy consumption and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] In the present embodiment, the preparation of the graphdiyne composite filter membrane and the desalination of sea water include the following steps:

[0063] 1) Using porous copper with a length of 5 cm, ultrasonically cleaned in water, ethanol and acetone in turn, and stored in acetone for subsequent use after treatment; in a three-necked flask, the porous copper was mixed with a solvent, and heated to 50 °C under argon protection. °C, wherein the solvent is a mixture of 100 mL of acetone and 5 mL of pyridine.

[0064] 2) 10 mg of hexaethynylbenzene was dissolved in 50 mL of acetone to obtain an acetone solution of hexaethynylbenzene.

[0065] 3) The acetone solution of hexaethynylbenzene in step 2) was slowly contacted with the mixture of porous copper and solvent in step 1) within 2h, and then the coupling reaction 1 was carried out at 50°C under argon and dark conditions. The graphdiyne composite filter membrane was prepared in 2019.

[0066] 4) Rinse the graphdi...

Embodiment 2

[0070] In this embodiment, in step 3), the reaction time of the polyacetylene compound and porous copper in the solvent is 3 days, and the remaining steps are the same as those in embodiment 1.

[0071] The results of the separation test in Example 2 are shown in Table 1.

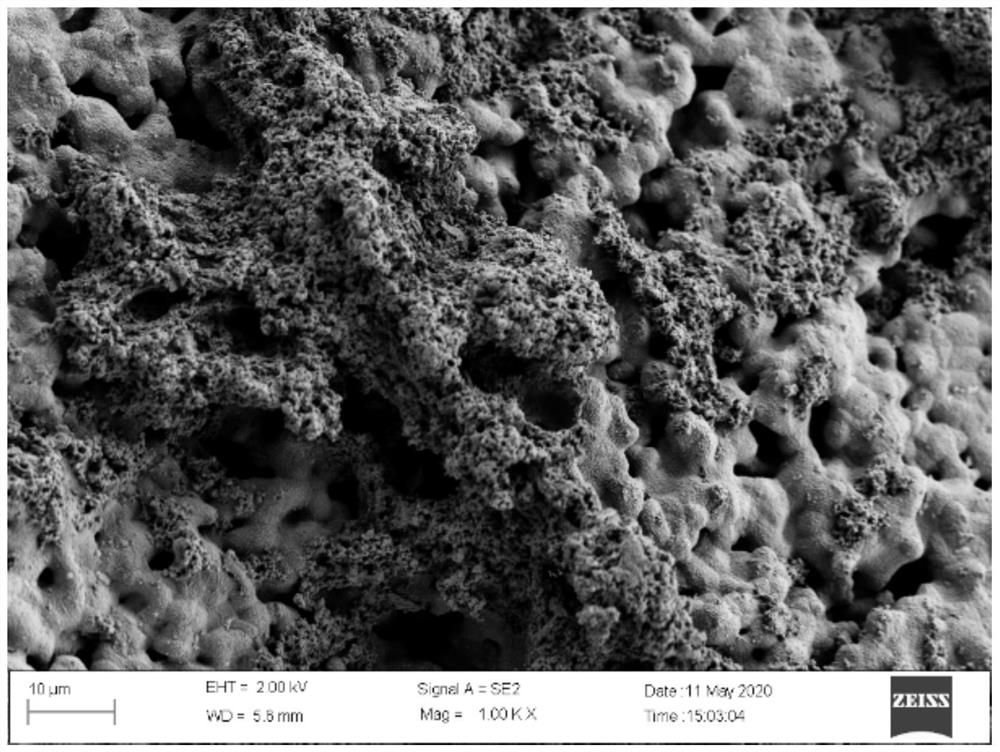

[0072] figure 2 is the SEM image of the graphdiyne composite filter membrane prepared in Example 2, from figure 1 It can be seen that the film cannot completely cover the surface of the porous copper, and the pores on the surface of the porous copper are directly exposed.

Embodiment 3

[0074] In this embodiment, in step 3), the reaction time of the polyacetylene compound and porous copper in the solvent is 5 days, and the remaining steps are the same as those in embodiment 1. In this embodiment, the thickness of the graphdiyne layer is 20 μm.

[0075] The results of the separation test in Example 3 are shown in Table 1.

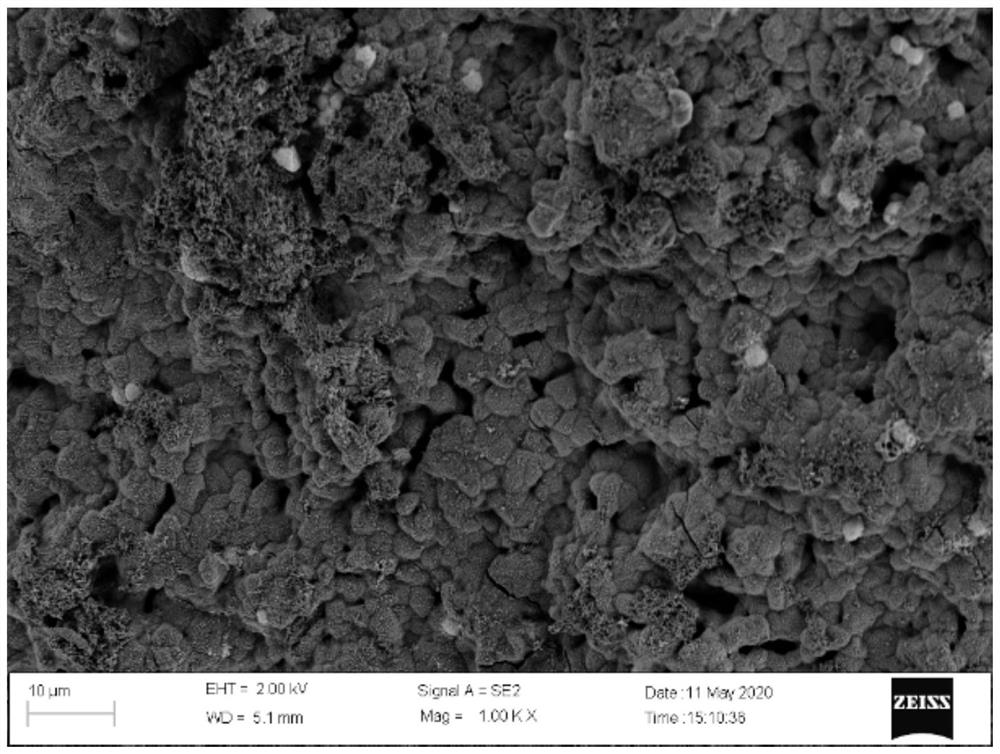

[0076] image 3 is the SEM image of the graphdiyne composite filter membrane prepared in Example 3, from figure 1 It can be seen that the graphdiyne layer completely covers the surface of porous copper and the graphdiyne layer is relatively loose.

[0077] Table 1

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com