Cleaning method for high-pressure tubular polyethylene reaction system

A tubular reaction and reaction system technology, used in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc. The effect of low body consumption, long production cycle and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

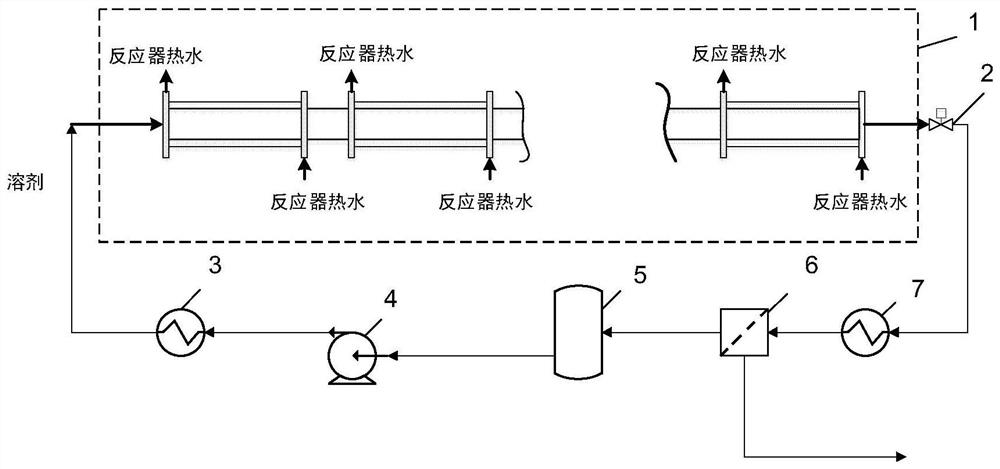

[0034] use as figure 1The high-pressure low-density polyethylene tubular reaction system cleaning process shown above is used for cleaning. Control the cleaning pressure inside the tubular reactor to 2.3MPa, and the cleaning temperature to 100°C, introduce the cleaning solvent component—toluene from the inlet of the tubular reactor, control the flow rate at 4-6m / s, and gradually dissolve and adhere to the Substances such as polyethylene on the pipe wall. The cleaned mixed solvent is exported from the outlet of the tubular reactor, and passes through the cooler and separator in turn to separate out the cleaned polyethylene and other impurities, and the recyclable solvent enters the cleaning process again. The entire cleaning process takes 30 hours , for multiple cleanings. Combined with the temperature and pressure changes of the reaction system before cleaning, comparing the reaction system before and after cleaning, it was found that the total pressure difference of the rea...

Embodiment 2

[0039] use as figure 1 The high-pressure low-density polyethylene tubular reaction system cleaning process shown above is used for cleaning. Control the cleaning pressure inside the tubular reactor to 2MPa, and the cleaning temperature to 125°C, introduce the cleaning solvent component—xylene from the inlet of the tubular reactor, control the flow rate at 4-6m / s, and gradually dissolve and adhere to the Substances such as polyethylene on the pipe wall. The cleaned mixed solvent is exported from the outlet of the tubular reactor, and passes through the cooler and separator in turn to separate out the cleaned polyethylene and other impurities, and the recyclable solvent enters the cleaning process again. The entire cleaning process takes 20 hours , for multiple cleanings. Combined with the temperature and pressure changes of the reaction system before cleaning, comparing the reaction system before and after cleaning, it was found that the total pressure difference of the react...

Embodiment 3

[0044] use as figure 1 The high pressure LDPE tubular reaction system shown is cleaned. The cleaning pressure inside the tubular reactor is controlled to be 2MPa, the cleaning temperature is 125°C, the solvent component for cleaning—xylene, is introduced from the inlet of the tubular reactor, and the flow rate is controlled at 4-6m / s. The pressure wave of the flow is realized by adjusting the pressure valve switch at the end of the reactor to realize the shock cleaning. By changing the opening of the pressure valve, a shock wave is formed in the tubular reactor, and the valve opening is periodically adjusted according to a certain frequency to gradually dissolve the formed polyethylene sticky wall material. The entire online cleaning process takes 15 hours and is carried out many times. cleaning. Under the same control conditions, comparing the reaction system before and after cleaning, it was found that after cleaning, the total pressure drop of the reaction system decrease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com