Method for separating and purifying vitamin K2 in fermentation liquor by using palm oil extract

A technology for separation and purification of vitamins, applied in quinone separation/purification, organic chemical methods, organic chemistry, etc., can solve the problems that the product cannot be directly consumed by the human body, serious pollution, complicated operation, etc., and achieve good mutual solubility, low freezing point, Good oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: A kind of method utilizing palm oil extract to isolate and purify vitamin K2 in fermented liquid

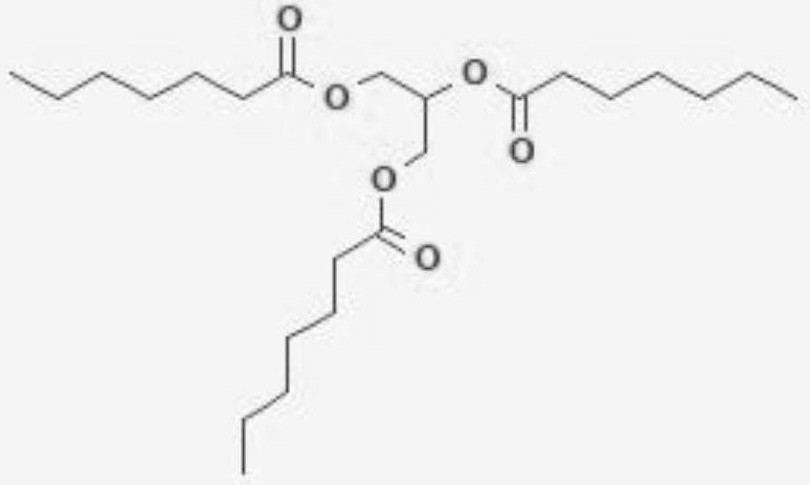

[0033] Using palm oil extract (medium-chain triglyceride) as a solvent to extract vitamin K2 from dry bacteria in one step, and to separate and purify high-purity vitamin K2 in two steps, mainly including the following steps:

[0034] (1) Strain seed culture. Bacillus natto or Bacillus subtilis needs to be cultured with seed liquid to obtain a certain amount of pure strain liquid before fermentation.

[0035] (2) Preparation of fermentation medium. Continuously optimize the composition of the fermentation medium through the feedback results of the fermentation experiment, and select the best fermentation medium formula for fermentation.

[0036] (3) Regulation of the fermentation process. Inoculate the seed solution in step (1) into the fermentation medium configured in step (2). The fermentation temperature is 35-40°C, and the rotation speed is kept at 2...

Embodiment 2

[0071] Embodiment 2: A kind of method utilizing palm oil extract to isolate and purify vitamin K2 in fermented liquid

[0072] Firstly, Bacillus natto is fermented, and the fermented wet cells are freeze-dried to obtain dry cells of Bacillus natto, and palm oil extract (medium chain triglyceride) is used as a solvent to extract the dry cells of Bacillus natto vitamin K2, and then use green non-toxic ethanol and butyl acetate as solvents for separation and purification, and obtain high-purity vitamin K2 in a green and efficient two-step method. details as follows:

[0073] The bacillus natto was fermented and cultivated in a 30L stirred reactor, and the filling volume was 80%. Inoculate the seed culture solution with 10% inoculum amount, ferment at 37°C and 250rpm, and monitor the bacterial concentration (OD method) during the cultivation until 156 hours later, the cultivation ends. Centrifuge the Bacillus natto or Bacillus subtilis fermentation liquid obtained by the microbi...

Embodiment 3

[0078] Embodiment 3: A kind of method utilizing palm oil extract to isolate and purify vitamin K2 in fermented liquid

[0079] A method utilizing palm oil extract to separate and purify vitamin K2 in fermented liquid, comprising the following steps:

[0080] Step 1: Separating the fermented liquid obtained by the microbial fermentation production method to obtain wet cells, and then freeze-drying the wet cells to obtain dry cells rich in vitamin K2;

[0081] Step 2: Mix the dried bacteria with the palm oil extract for 2 hours, then centrifuge the mixture to take the supernatant, and the obtained supernatant is the palm oil extract rich in vitamin K2;

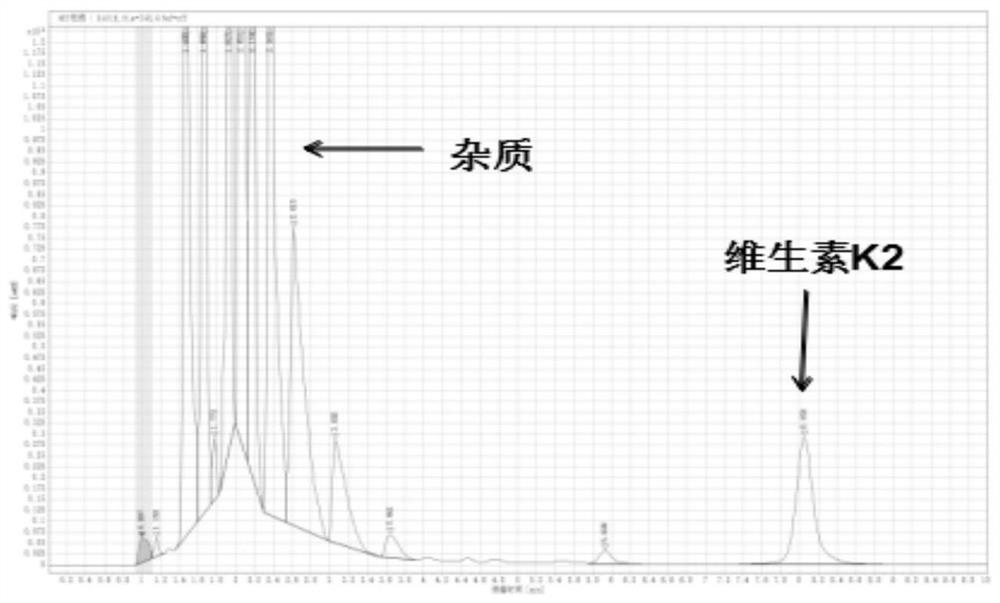

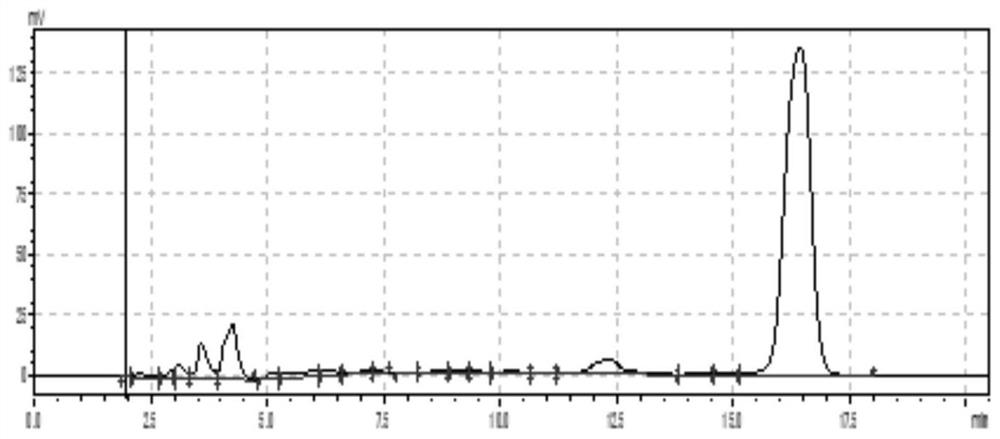

[0082] Step 3: Pack the pretreated macroporous resin into a column, place the vitamin K2-rich palm oil extract in a separation column filled with macroporous resin, use the first eluent to remove miscellaneous oils, and then use the second A resolving agent elutes vitamin K2 from the macroporous resin to obtain an eluent;

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com