Method to optimize atomic layer deposition

An atomic layer deposition method, atomic layer deposition technology, applied in the direction of coating, gaseous chemical plating, metal material coating process, etc., can solve the problem of poor water and gas barrier properties, limited improvement of gas barrier properties, color changes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

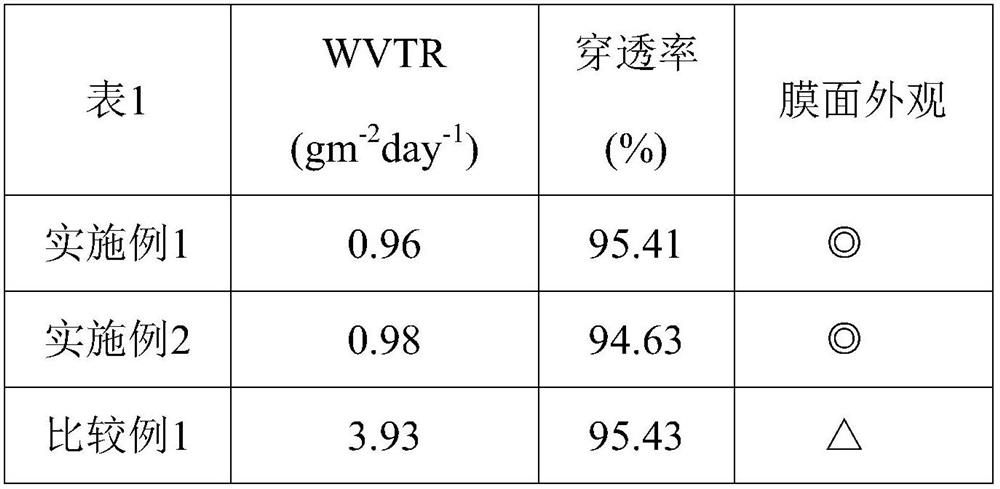

Examples

preparation example 1

[0049] Preparation Example 1: The preparation method of linear polysiloxane (Compound A)

[0050]3499.92 grams (19.13 mole) of methylphenyl dimethoxysilane (phenylmethyldimethoxysilane, purchased from Hengqiao Industrial Co., Ltd., Taiwan), 288.48 grams (2.4 mole) of dimethyldimethoxysilane (Dimethyldimethoxysilane, Purchased from Hengqiao Industrial Co., Ltd., Taiwan), and 317.28 grams (2.4mole) of methylvinyldimethoxysilane (Methylvinyldimethoxysilane, purchased from Liuhe Chemical Co., Ltd., Taiwan) was added to the reaction tank and Stir at room temperature to form a homogeneous mixed solution. This mixed solution is dripped in the sulfuric acid aqueous solution (5337.4 grams) of concentration 5% to obtain a reaction solution, then this reaction solution is heated to 75 ℃ to carry out hydrolysis, after the reaction is complete, extract with deionized water to make the organic layer reach neutral. properties, and finally the solvent is removed to obtain a hydrolyzate.

[...

preparation example 2

[0052] Preparation example 2: the preparation method of the first silicone resin (compound B)

[0053] 2776 grams (14 mole) of phenyl-trimethoxysilane (phenyl-trimethoxysilane, purchased from Liuhe Co., Ltd., Taiwan), 480.88 grams (4 mole) of dimethyldimethoxysilane (Dimethyldimethoxysilane, purchased from Hengqiao Industrial Co., Ltd., Taiwan), and 264.46 grams (2mole) of methylvinyldimethoxysilane (Methylvinyldimethoxysilane, purchased from Liuhe Chemical Co., Ltd., Taiwan) is placed in the reaction tank, stirred at room temperature to prepare Mix the solution evenly. Drop the mixed solution into 5% sulfuric acid aqueous solution to prepare a reaction solution, then heat the reaction solution to 75°C for hydrolysis, after the reaction is complete, extract with deionized water to make the organic layer neutral, and finally The solvent was removed to give the monohydrolyzate.

[0054] The above-mentioned hydrolyzate, 21.39 grams (0.11 mole) of divinyltetramethyldisiloxane (D...

preparation example 3

[0055] Preparation example 3: the preparation method of the second silicone resin (compound C)

[0056] With 2379.4 grams (12 mole) of phenyl trimethoxysilane (Phenyltrimethoxysilane, purchased from Liuhe Chemical Co., Ltd., Taiwan), and 1118.4 grams (6 mole) of divinyltetramethyldisiloxane (Divinyltetramethyldisiloxane, purchased from Liuhe Chemical Co., Ltd., Taiwan) was placed in a reaction tank and stirred at room temperature to obtain a uniform mixed solution. This mixed solution was dripped into 5% sulfuric acid aqueous solution (4547.16 grams) to prepare a reaction solution, and then the reaction solution was heated to 75°C for hydrolysis, and after the reaction was complete, it was extracted with deionized water to make The organic layer was neutralized, and finally the solvent was removed to obtain a hydrolyzate.

[0057] The above-mentioned hydrolyzate, 1998 grams of toluene and 10 grams of potassium hydroxide were placed in a reaction tank, nitrogen gas was introdu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com