Lithium-sulfur battery electrolyte additive, electrolyte and lithium-sulfur battery

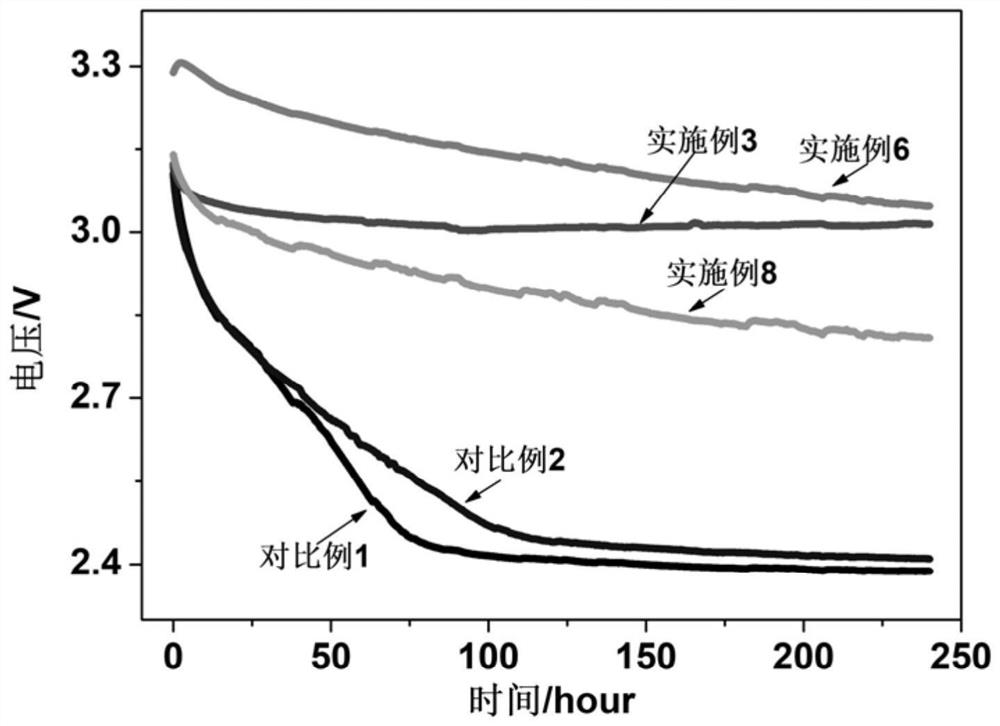

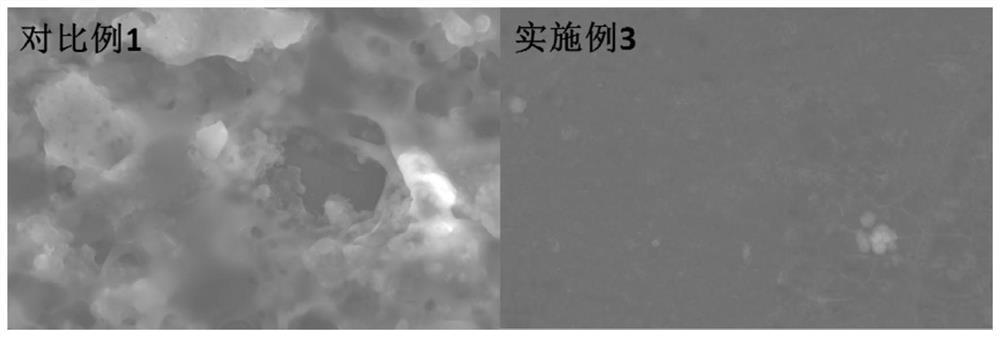

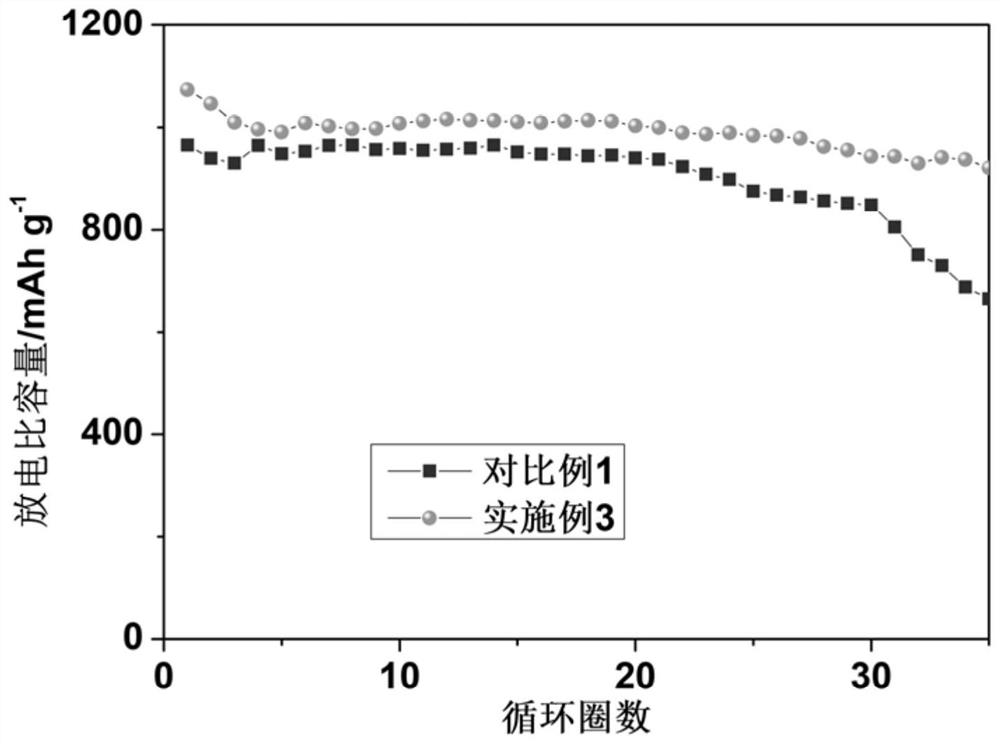

An electrolyte additive and lithium-sulfur battery technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems affecting battery cycle performance, cycle stability decline, active material extraction, etc. Discharge phenomenon, polysulfide ion elution reduction, effect of promoting conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of lithium-sulfur battery:

[0023] Use elemental sulfur as the positive electrode active material, add conductive agent, binder and solvent, stir and mix evenly, coat on aluminum foil, dry, roll, and cut to make the positive electrode sheet respectively; use metal lithium as the negative electrode active material The materials are cut by lithium strips and copper foils and then rolled to obtain negative electrode sheets. The positive and negative pole pieces and the polypropylene separator are assembled into a square lithium-sulfur battery by lamination. The battery is injected with liquid, and after being sealed, the lithium-sulfur battery is obtained by chemical formation, air extraction and sealing.

[0024] (2) Preparation of electrolyte

[0025] In a glove box filled with argon (moisture content <0.1ppm, oxygen content <0.1ppm), mix ethylene glycol dimethyl ether and 1,3-dioxolane at a volume ratio of 1:1 and keep Stir, slowly add 1.0mol / L lithi...

Embodiment 2

[0027] (1) Preparation of lithium-sulfur battery according to the method described in Example 1

[0028] (2) Preparation of electrolyte

[0029] In a glove box filled with argon (moisture content <0.1ppm, oxygen content <0.1ppm), mix ethylene glycol dimethyl ether and 1,3-dioxolane at a volume ratio of 1:1 and keep Stir, slowly add 1.0mol / L lithium bistrifluoromethanesulfonimide to the mixed solvent, then add lithium nitrate and 0.5% lithium difluorophosphate with a mass fraction of 2.0%, stir until completely dissolved, and obtain the present Example electrolyte.

Embodiment 3

[0031] (1) Preparation of lithium-sulfur battery according to the method described in Example 1

[0032] (2) Preparation of electrolyte

[0033] In a glove box filled with argon (moisture content <0.1ppm, oxygen content <0.1ppm), mix ethylene glycol dimethyl ether and 1,3-dioxolane at a volume ratio of 1:1 and keep Stir, slowly add 1.0mol / L lithium bistrifluoromethanesulfonimide to the mixed solvent, then add lithium nitrate and 1.0% lithium difluorophosphate with a mass fraction of 2.0%, stir until completely dissolved, and obtain the present Example electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com