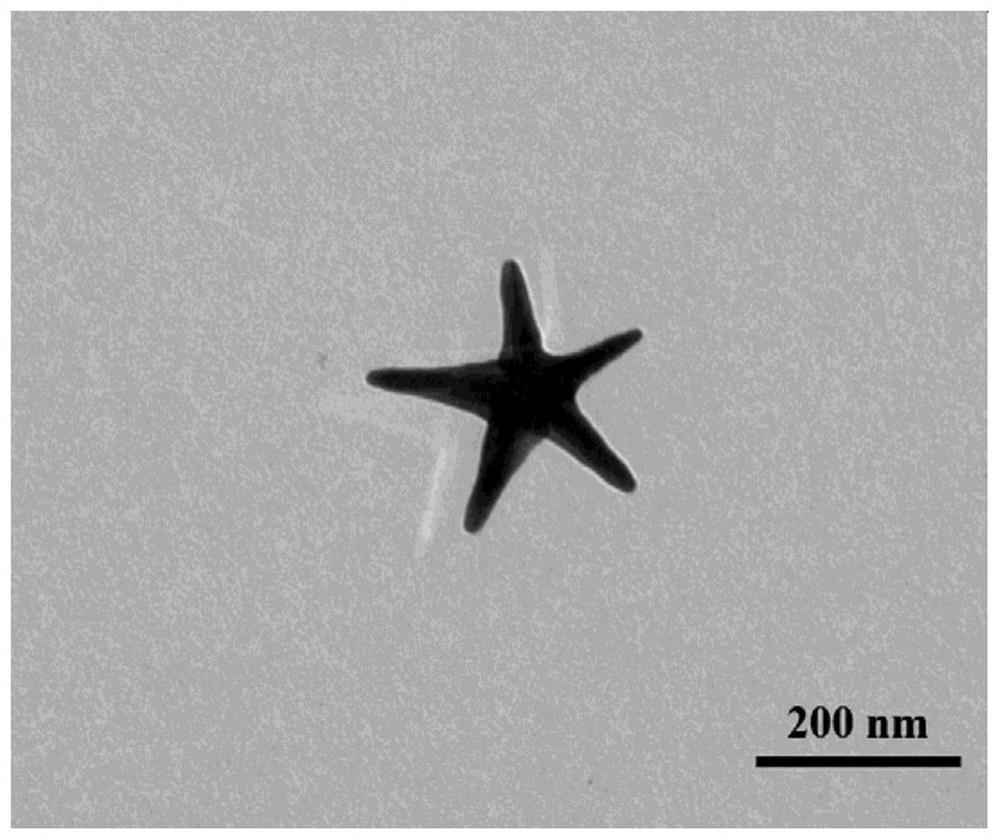

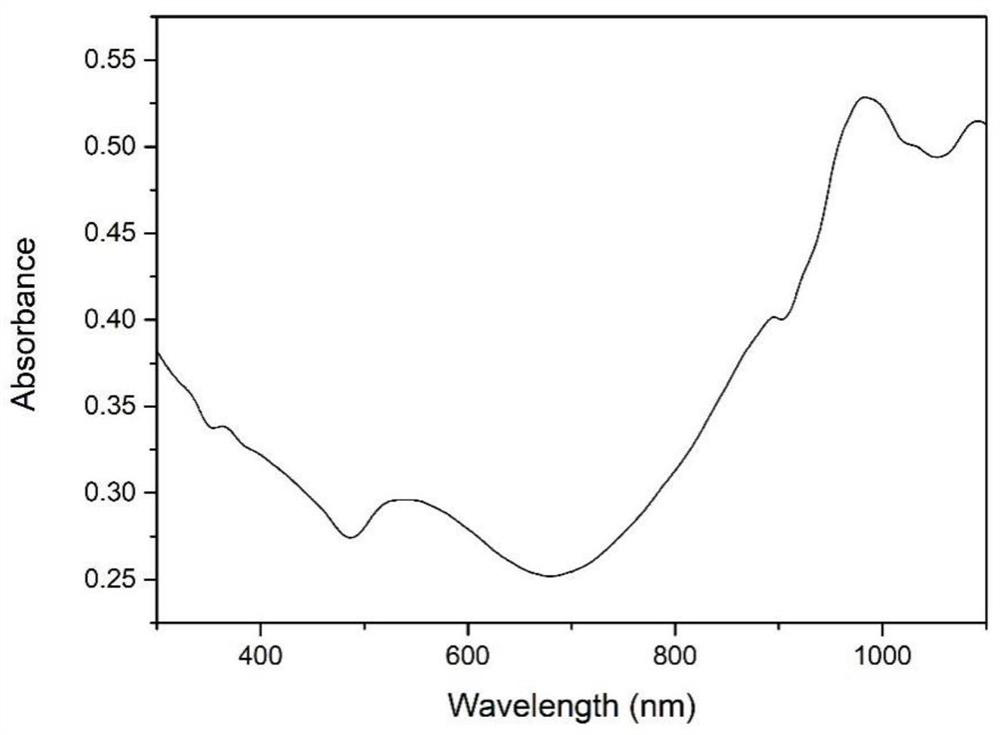

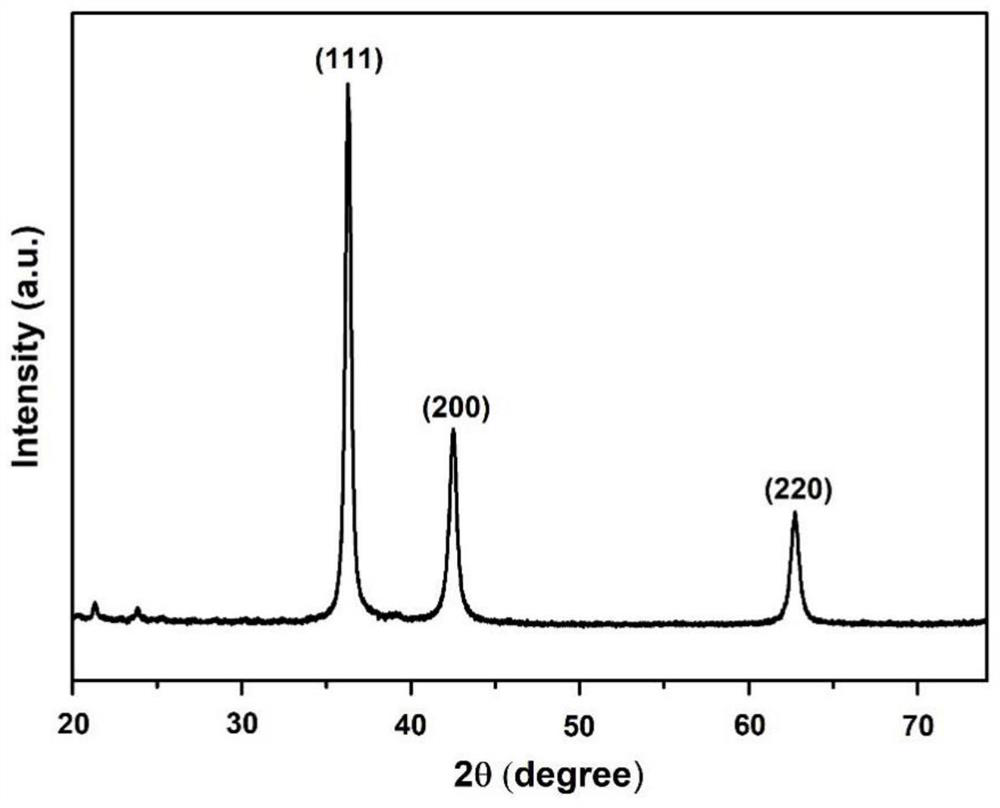

A preparation method of photothermal antibacterial near-infrared bimetallic nanoparticles

A bimetallic nanometer and near-infrared technology, applied in botany equipment and methods, chemicals for biological control, disinfection, etc., can solve the problems of drug resistance, side effects of antibacterial materials, large antibacterial dose, etc., and achieve improved sterilization The effect of activity, strong light-to-heat conversion ability, and good bactericidal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing photothermal antibacterial near-infrared bimetallic nanoparticles, comprising the following steps:

[0041] Step 1, weigh 0.03 g of chloroauric acid, 0.026 g of copper chloride, 0.25 g of glucose and 0.1 g of hexadecylamine in a 50 mL scintillation vial, add 25 mL of ultrapure water, and stir at room temperature at 600 r / min for 18 h.

[0042] Step 2, transfer the scintillation vial to an oil bath, and react for 0.5 h at 100 °C, stirring at 600 r / min.

[0043] Step 3, after the reaction is completed, the product to be synthesized is cooled to 25 °C.

[0044] In step 4, the obtained brown-black solution was placed in a centrifuge and centrifuged at 10,000 rpm for 8 min, and 25 mL of deionized water was added to the obtained precipitate, and it was dispersed by ultrasonication at room temperature for 10 min.

[0045] Step 5, put the above solution in a centrifuge and centrifuge at 10,000 rpm for 8 min. After repeating three times, add 25 mL of eth...

Embodiment 2

[0052] A method for preparing photothermal antibacterial near-infrared bimetallic nanoparticles, comprising the following steps:

[0053] Step 1, weigh 0.03 g of chloroauric acid, 0.026 g of copper chloride, 0.25 g of glucose and 0.45 g of hexadecylamine in a 50 mL scintillation vial, add 25 mL of ultrapure water, and stir at room temperature at 600 r / min for 18 h.

[0054] Step 2, transfer the scintillation vial to an oil bath, and react for 0.5 h at 100 °C, stirring at 600 r / min.

[0055] Step 3, after the reaction is completed, the product to be synthesized is cooled to 25 °C.

[0056] In step 4, the obtained brown-black solution was placed in a centrifuge and centrifuged at 10,000 rpm for 8 min, and 25 mL of deionized water was added to the obtained precipitate, and it was dispersed by ultrasonication at room temperature for 10 min.

[0057] Step 5, put the above solution in a centrifuge and centrifuge at 10,000 rpm for 8 min. After repeating three times, add 25 mL of et...

Embodiment 3

[0062] A method for preparing photothermal antibacterial near-infrared bimetallic nanoparticles, comprising the following steps:

[0063] Step 1, weigh 0.03 g of chloroauric acid, 0.026 g of copper chloride, 0.25 g of glucose and 0.35 g of hexadecylamine in a 50 mL scintillation vial, add 25 mL of ultrapure water, and stir at room temperature at 600 r / min for 18 h.

[0064] Step 2, transfer the scintillation vial to an oil bath, and react for 0.5 h at 100 °C, stirring at 600 r / min.

[0065] Step 3, after the reaction is completed, the product to be synthesized is cooled to 25 °C.

[0066] In step 4, the obtained brown-black solution was placed in a centrifuge and centrifuged at 10,000 rpm for 8 min, and 25 mL of deionized water was added to the obtained precipitate, and it was dispersed by ultrasonication at room temperature for 10 min.

[0067] Step 5, put the above solution in a centrifuge and centrifuge at 10,000 rpm for 8 min. After repeating three times, add 25 mL of et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com