Preparation method of cuttlefish-flavored seafood powder for quick-frozen food

A technology of quick-frozen food and a production method, which is applied in the field of seafood powder, and can solve the problems of not being able to meet the application needs of quick-frozen seafood food, taste, heat stability, or insufficient nutrition, and sensory characteristics that are not easily accepted by consumers, so as to facilitate filtration and satisfy the senses Requirements, the effect of improving the leaching yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

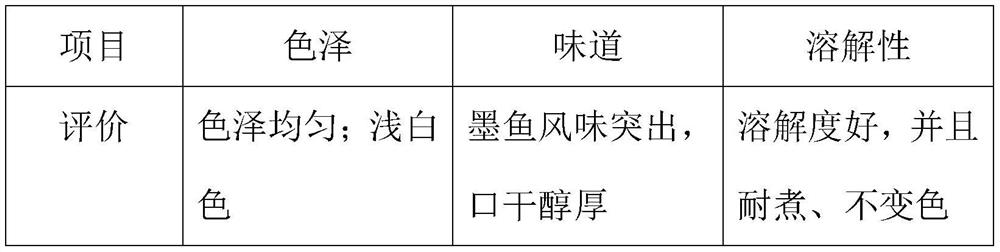

Examples

Embodiment 1

[0022] A method for preparing squid-flavored seafood powder for quick-frozen food, the steps are as follows:

[0023] Step 1, raw material mincing: take 100 parts of cuttlefish by weight and pass through a meat grinder to mince;

[0024] Step 2, ultrasonic treatment: add 3 times the weight of pure water to the raw material of step 1, and 200w ultrasonic treatment for 15min;

[0025] Step 3, extraction: heat up the raw material treated in step 2 to 80°C, heat-preserve and extract for 16 hours;

[0026] Step 4. Controllable enzymatic hydrolysis: Cool the feed liquid treated in step 3 to 40°C, add 1mol / L hydrochloric acid solution, adjust the pH to 4.0, add 0.02% cellulase according to the total mass of cuttlefish, and perform enzymatic hydrolysis for 0.5h , heat up to 50°C, add xylanase at 0.03%, hydrolyze for 1h, add 2mol / L sodium hydroxide solution, adjust pH to 8.0, add 0.2% alkaline protease, hydrolyze for 2h, then add 0.5mol / L Hydrochloric acid solution, adjust the pH to ...

Embodiment 2

[0031] A method for preparing squid-flavored seafood powder for quick-frozen food, the steps are as follows:

[0032] Step 1, raw material mincing: take 100 parts of cuttlefish by weight and pass through a meat grinder to mince;

[0033] Step 2, ultrasonic treatment: add 3 times the weight of pure water to the raw material of step 1, and 300w ultrasonic treatment for 10 minutes;

[0034] Step 3, extraction: heat up the raw material treated in step 2 to 70°C, heat-preserve and extract for 18 hours;

[0035] Step 4. Controllable enzymatic hydrolysis: Cool the feed liquid treated in step 3 to 45°C, add 1mol / L hydrochloric acid solution, adjust the pH to 5.0, add 0.03% cellulase according to the total mass of cuttlefish, and perform enzymatic hydrolysis for 0.5h , heat up to 55°C, add xylanase at 0.05%, hydrolyze for 2h, add 2mol / L sodium hydroxide solution, adjust pH to 9.0, add 0.3% alkaline protease, hydrolyze for 3h, then add 0.5mol / L Hydrochloric acid solution, adjust the p...

Embodiment 3

[0040] A method for preparing squid-flavored seafood powder for quick-frozen food, the steps are as follows:

[0041] Step 1, raw material mincing: take 100 parts of cuttlefish by weight and pass through a meat grinder to mince;

[0042] Step 2, ultrasonic treatment: add 3 times the weight of pure water to the raw material of step 1, and 120w ultrasonic treatment for 20min;

[0043] Step 3, extraction: heat up the raw material treated in step 2 to 85°C, heat-preserve and extract for 17 hours;

[0044] Step 4. Controllable enzymatic hydrolysis: Cool the feed liquid treated in step 3 to 42°C, add 1mol / L hydrochloric acid solution, adjust the pH to 4.5, add 0.025% cellulase according to the total mass of cuttlefish, and perform enzymatic hydrolysis for 1 hour. Heat up to 55°C, add xylanase at 0.05%, hydrolyze for 3h, add 2mol / L sodium hydroxide solution, adjust pH to 8.5, add 0.25% alkaline protease, hydrolyze for 2.5h, then add 0.5mol / L Hydrochloric acid solution, adjust the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com