Wheat protein peptide with blood pressure-lowering activity and preparation method of wheat protein peptide

A wheat protein peptide and blood pressure lowering technology, which is applied in medical preparations containing active ingredients, peptide/protein components, protein food processing, etc., can solve the problem of increasing procedures, electrolyzed water pretreatment of bioactive peptides, and harmful Alanine and other problems to achieve the effect of improving hydrolysis efficiency and good resistance to gastrointestinal digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

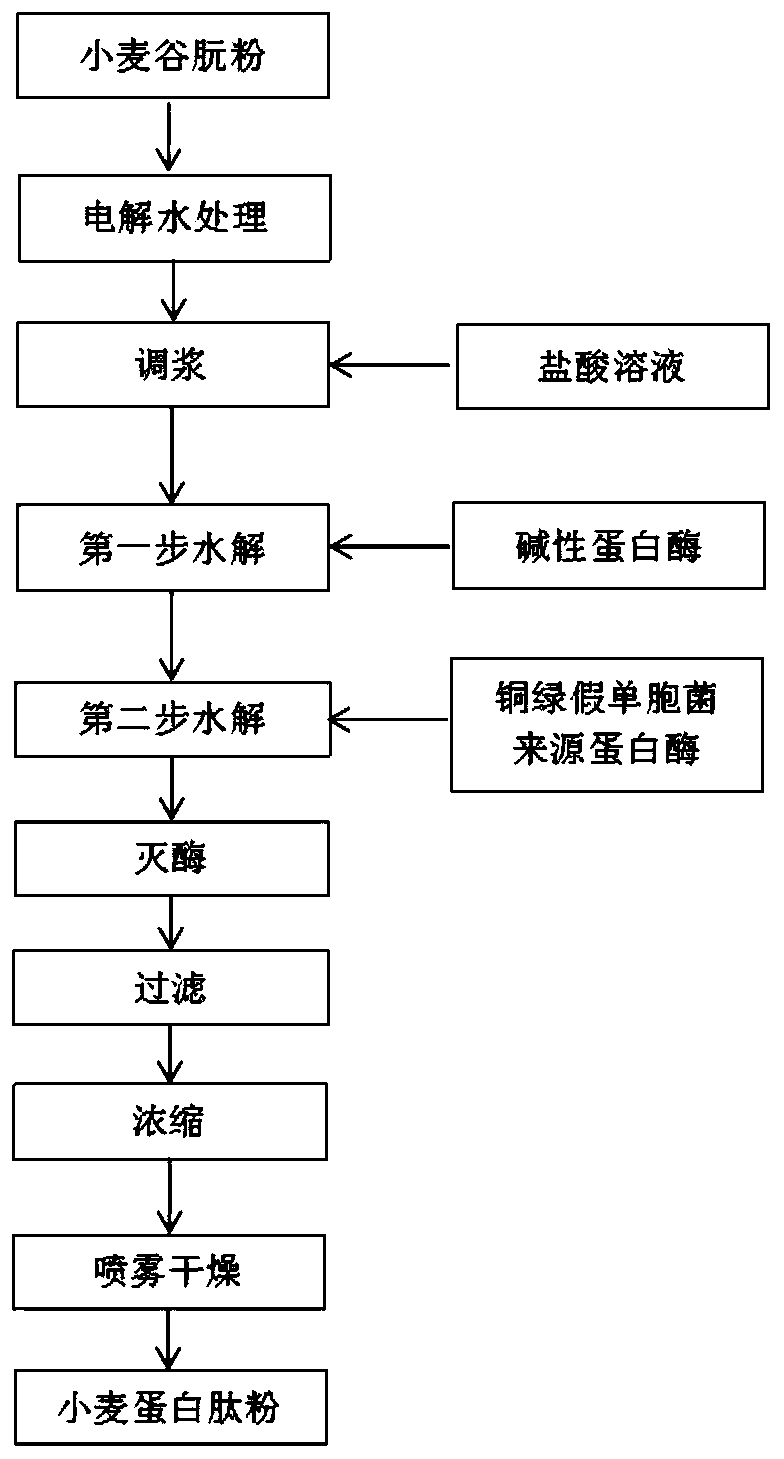

[0070] The preparation process flow diagram of hypotensive active wheat protein peptide is as follows figure 1 As shown, the specific steps are as follows:

[0071] Add laboratory-made electrolyzed water (using CE-7001 electrolyzer (Guangzhou Saiai Environmental Protection Technology Development Co., Ltd.), electrolytic solution is 0.1% sodium chloride solution, electrolyzed for 5min under 40V voltage condition) into the enzymolysis tank. Start the stirring paddle, add wheat gluten slowly, and stir for 2-4 hours after adding; add 1M hydrochloric acid solution or 1M sodium hydroxide solution to the enzymolysis tank with a peristaltic pump to adjust the pH value to 8.0-9.5, and continue stirring for 30 minutes to obtain For the wheat gluten suspension, heat the heater to 45-55°C and keep it warm; add alkaline protease to the wheat gluten suspension, the addition amount is 500-1500U / g, after hydrolysis for 6 hours, add Pseudomonas aeruginosa Source protease, add 500-1000U / g, con...

Embodiment 1

[0079] Embodiment 1 wheat gluten hydrolysis condition optimization

[0080] Prepare 100mL of wheat gluten suspension with 5% concentration (adding 5g wheat gluten in 100ml distilled water), use 1M sodium hydroxide solution or 1M hydrochloric acid to adjust the pH of the suspension to the optimum condition, and use Danoxin respectively Weixin alkaline protease, compound protease and laboratory-made Pseudomonas aeruginosa-derived protease hydrolyze wheat gluten suspension step by step with single enzyme or two enzymes, and the total enzyme amount added is 5000U. After hydrolysis for 10 hours under optimal conditions, inactivate in a boiling water bath for 10 minutes, centrifuge to obtain wheat gluten hydrolyzate, measure the ACE inhibition rate of each, and calculate its IC 50 value. The hydrolysis conditions and the results of the ACE inhibition rate determined are shown in Table 1. Determination of ACE inhibitory activity was slightly modified with reference to the method of...

Embodiment 2

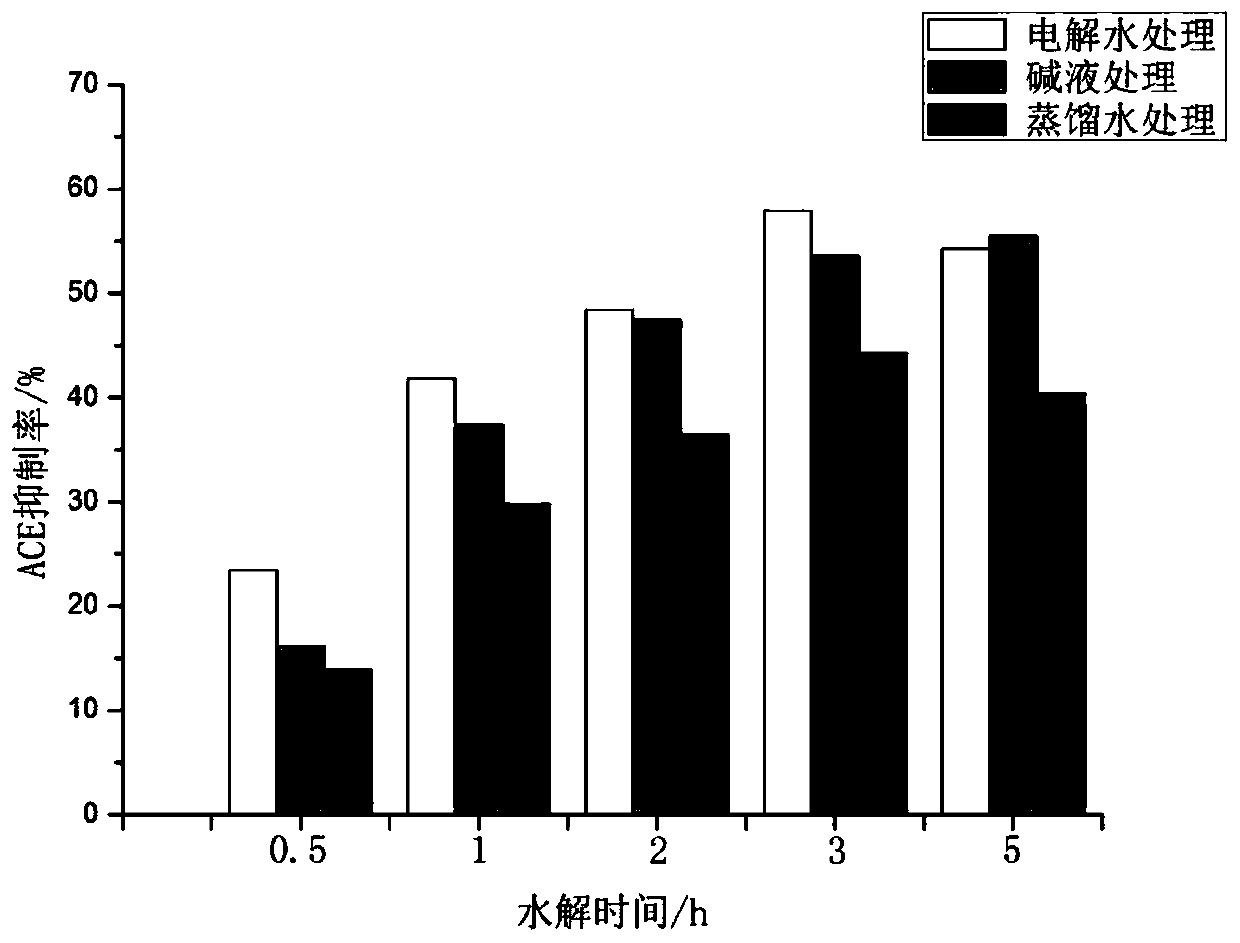

[0090] Example 2 Effects of alkaline electrolyzed water immersion treatment and lye immersion treatment on the hydrolysis of wheat gluten

[0091] Respectively adopt self-made alkaline electrolyzed water with a pH value of 11 (using CE-7001 electrolytic cell (Guangzhou Saiai Environmental Protection Technology Development Co., Ltd.), the electrolytic solution is 0.1% sodium chloride solution, electrolyzed at 40V for 5min, The solution produced near the cathode is alkaline electrolyzed water) and sodium hydroxide solution soaking wheat gluten for 8h, and then freeze-dried for subsequent use. In addition, wheat gluten was soaked in distilled water for 8 hours and then freeze-dried for later use. Take three pretreated gluten powders to prepare 100mL of 5% suspension, adjust the pH to 8.5, add 5000U Novozymes alkaline protease, hydrolyze at 50°C for 5h, take 30min, 1h, 2h respectively , 3h, and 5h samples were inactivated in a boiling water bath for 10 minutes, centrifuged to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com