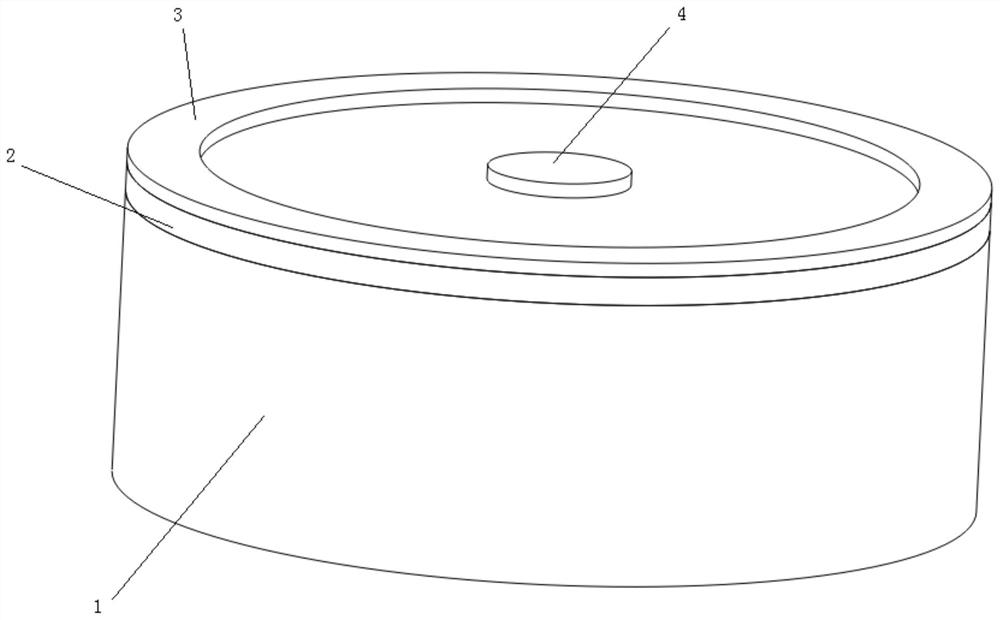

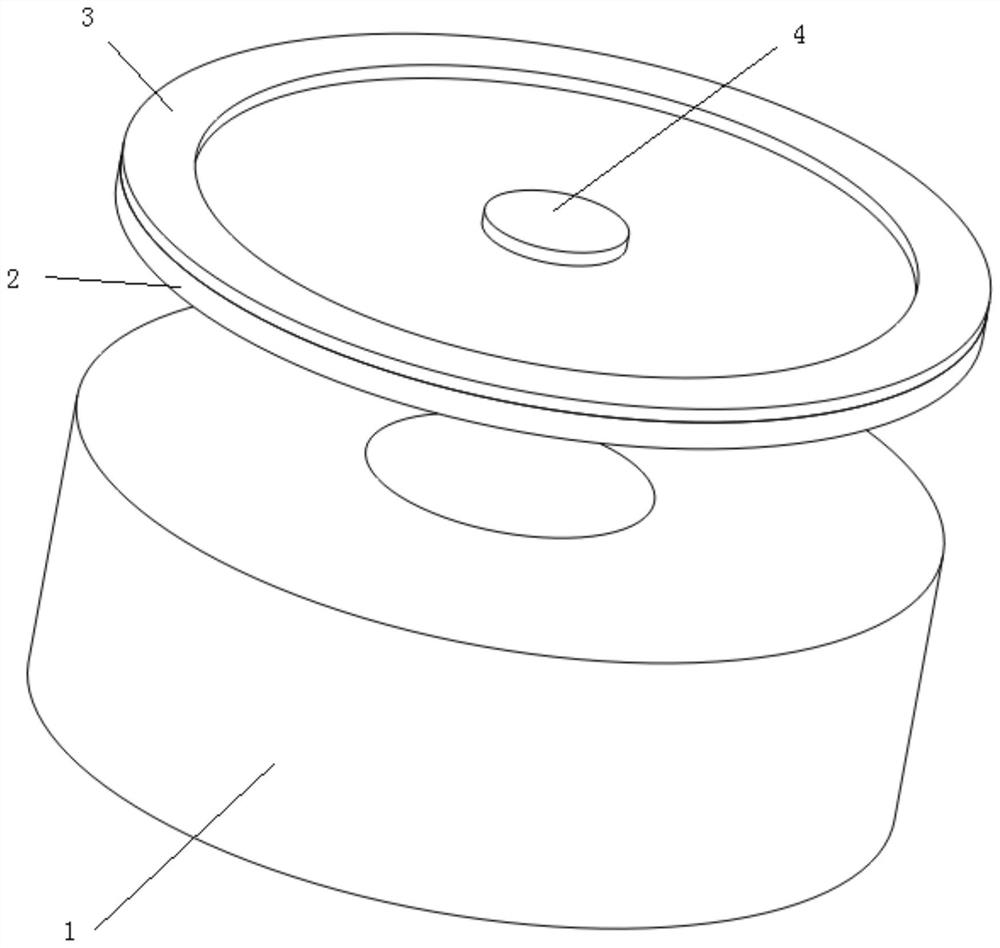

Heating and atomizing structure of miniature semiconductor heating atomizer and manufacturing method thereof

A heating atomization and production method technology, applied in the field of atomizers, can solve the problems of waste of electric energy, cumbersome production process, resistance value change of resistance wire, etc. The effect of a wide range of values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Step 1: Take 2 parts of tin tetrachloride pentahydrate and 3 parts of stannous chloride and mix thoroughly, then add 5 parts of glacial acetic acid, and stir at 8°C until all solid particles are dissolved; then add 0.3 parts of glycerin Continue stirring for 5 minutes to obtain component 1; take 5 parts of hydrochloric acid, add 5 parts of antimony trichloride dihydrate and 0.6 parts of aluminum chloride, and stir evenly at 15°C to obtain component 2; take 15 parts of ethanol, add oxidation Mix 0.5 part of tin and 0.8 part of bismuth oxide to obtain component three.

[0020] Step 2: add all components 1 and 2 obtained in step 1 into component 3, then slowly add 15 parts of distilled water, filter out solid particles after fully reacting, and obtain a semiconductor electrothermal membrane treatment solution with a good ratio; store Place it in a room at 15°C during use, and fully stir it at room temperature during use.

[0021] Step 3, heat the processed substrate to 38...

Embodiment 2

[0024] Step 1: Take 10 parts of tin tetrachloride pentahydrate and 6 parts of stannous chloride and mix thoroughly, then add 10 parts of glacial acetic acid and stir at 12°C until all solid particles are dissolved; then add 1 part of glycerol Continue stirring for 10 minutes to obtain component 1; take 10 parts of hydrochloric acid, add 10 parts of antimony trichloride dihydrate and 1 part of aluminum chloride, and stir evenly at 20°C to obtain component 2; take 25 parts of ethanol, add oxidation Mix 0.7 parts of tin and 1.5 parts of bismuth oxide to obtain component three.

[0025] Step 2: add all components 1 and 2 obtained in step 1 to component 3, then slowly add 30 parts of distilled water, and filter out solid particles after fully reacting to obtain a semiconductor electrothermal membrane treatment solution with a good ratio; store Place it in a room at 25°C when using it, and stir it well at room temperature when using it.

[0026] Step 3: Heat the processed substrate...

Embodiment 3

[0029] Step 1: Take 6 parts of tin tetrachloride pentahydrate and 4.5 parts of stannous chloride and mix thoroughly, then add 7.5 parts of glacial acetic acid and stir at 10°C until all solid particles are dissolved; then add 0.65 parts of glycerol Continue stirring for 7.5 minutes to obtain component 1; take 7.5 parts of hydrochloric acid, add 7.5 parts of antimony trichloride dihydrate and 0.8 parts of aluminum chloride, and stir evenly at 17.5°C to obtain component 2; take 20 parts of ethanol, add Mix 0.6 parts of tin oxide and 1.15 parts of bismuth oxide to obtain component three.

[0030] Step 2: add all components 1 and 2 obtained in step 1 to component 3, then slowly add 22.5 parts of distilled water, and filter out solid particles after fully reacting to obtain a semiconductor electrothermal membrane treatment solution with a good ratio; store Place it in a room at 20°C when using it, and stir it well at room temperature when using it.

[0031] Step 3, heat the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com