Preparation method for synthesizing ZIF-67 membrane through in-hole membrane formation

A ZIF-67, film-forming technology, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problems of high process difficulty, swelling, poor stability, low strength, etc., to reduce environmental pollution and simple preparation process. , high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

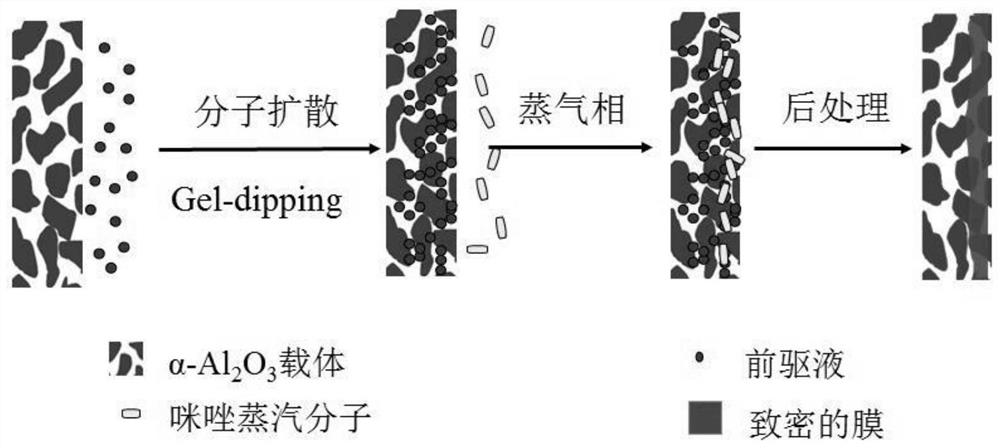

Method used

Image

Examples

Embodiment 1

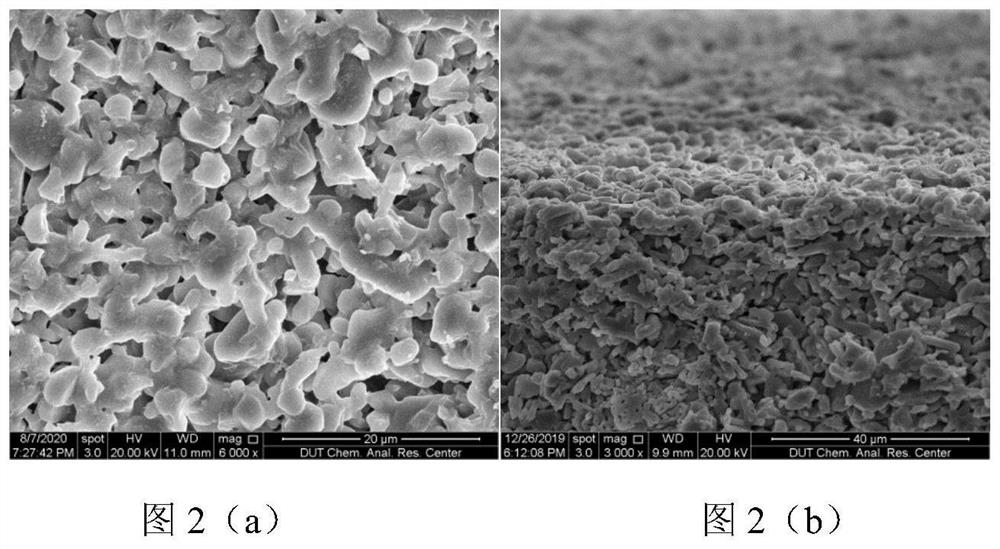

[0040] (1) Pretreatment α-Al 2 o 3Carrier tube: the outer diameter of the tube is 12mm, the inner diameter of the tube is 8mm, the average pore diameter is 2-3μm, and the porosity is about 30-40%; the outer surface of the carrier tube is polished with 800 mesh and 1500 mesh sandpaper; it is removed by ultrasonic vibration with deionized water The remaining sand particles on the carrier tube are repeated several times until the water used for washing the tube is no longer turbid, then ultrasonically shake with acid and alkali in order to remove the residue in the carrier pores, and wash with deionized water until neutral; finally The tube was dried in an oven, then calcined in a muffle furnace at 550°C for 6 hours, and both ends were sealed for later use;

[0041] (2) Add 5g of cobalt acetate and 30mL of ethylene glycol methyl ether into a 100mL beaker, stir in a water bath at 75°C for 60min, then add 2ml of 2-aminoethanol, and stir at room temperature for 12h to obtain a prec...

Embodiment 2

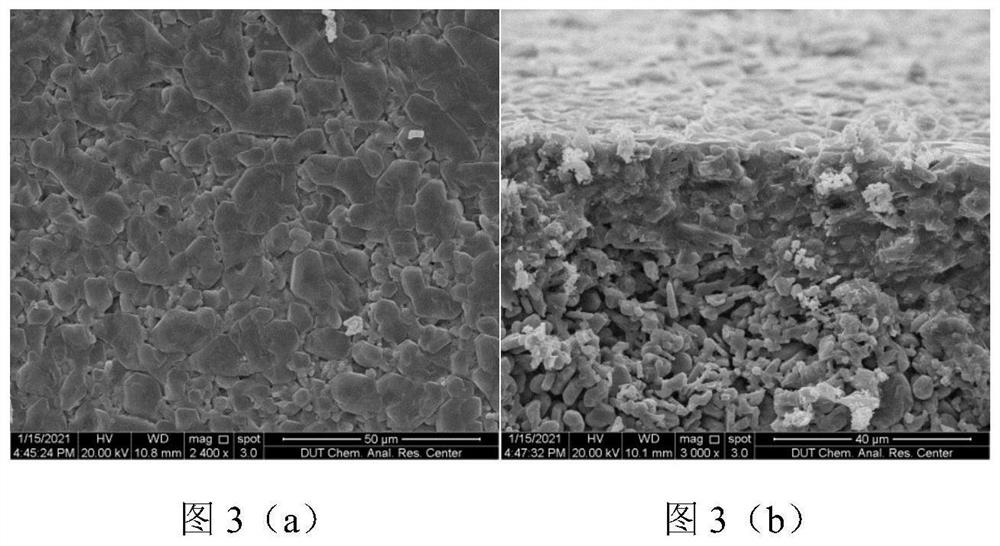

[0046] (1) Pretreatment α-Al 2 o 3 Carrier tube: the outer diameter of the tube is 12mm, the inner diameter of the tube is 8mm, the average pore diameter is 2-3μm, and the porosity is about 30-40%; the outer surface of the carrier tube is polished with 800 mesh and 1500 mesh sandpaper; it is removed by ultrasonic vibration with deionized water The remaining sand particles on the carrier tube are repeated several times until the water used for washing the tube is no longer turbid, then ultrasonically shake with acid and alkali in order to remove the residue in the carrier pores, and wash with deionized water until neutral; finally The tube was dried in an oven, then calcined in a muffle furnace at 550°C for 6 hours, and both ends were sealed for later use;

[0047] (2) Add 5g of cobalt nitrate hexahydrate and 30mL of ethylene glycol methyl ether into a 100mL beaker, stir in a water bath at 75°C for 60min, then add 2ml of 2-aminoethanol, and stir at room temperature for 12h to ...

Embodiment 3

[0052] The gas-phase filled synthetic ZIF-67 membrane prepared in Example 1 was tested for single-component gas and pressure, and the test results are shown in the figure below. After testing, H 2 The permeate flux range is 2.50×10 -7 mole m -2 ·s -1 pa -1 , H 2 / CH 4, The separation factor is 15, which is far greater than Knudsen diffusion, which proves the feasibility of this method and has a certain separation ability for gases; when the pressure is increased, H 2 / CH 4 The separation factor remained basically stable, indicating strong applicability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Tube inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com