Preparation method of nitrated graphene oxide

A graphene, nitration technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., to achieve the effects of good dispersion, low cytotoxicity, and strong antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

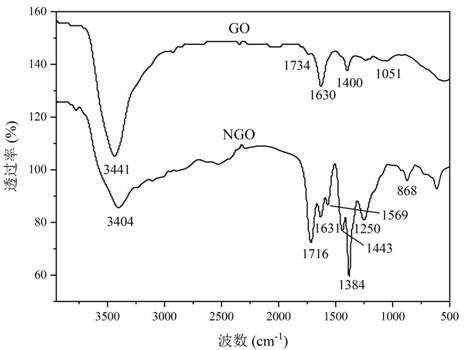

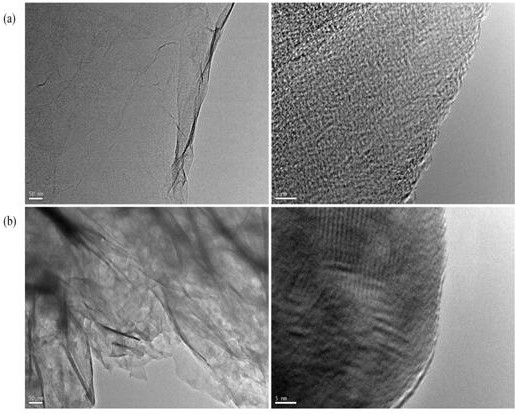

[0021] (1) Preparation of GO

[0022] ① Take 24 mL concentrated H 2 SO 4 into a 100 mL beaker, heated in an oil bath to 80°C, and added K 2 S 2 o 8 and P 2 o 5 5g each, stir evenly, then add 6g of graphite powder, pre-oxidize for 4.5 h. After the reaction was completed, 1000 mL of deionized water was added to the above mixture and allowed to stand for 12 h, the supernatant was discarded, the precipitate was suction-filtered to dryness, and dried at 60 °C for 24 h before use.

[0023] ② Add the above pre-oxidized dry graphite powder to 240 mL of cold concentrated H 2 SO 4 , stir well and add KMnO 4 Powder 30 g, put the beaker in an ice-water bath, keep the temperature of the reaction system in this step below 20 ° C, to KMnO 4 completely dissolved.

[0024] ③The temperature of the mixed system was raised to 35 °C and stirred for 2 h, then 500 mL of deionized water was added to the reaction system and stirred for 2 h. Then add 1.4 L of deionized water and 40 mL of 30...

Embodiment 2

[0033] (1) Preparation of GO: Same as Example 1;

[0034] (2) Preparation of nitrated graphene oxide (NGO)

[0035] ① Add the above GO to deionized water to obtain a GO dispersion with a concentration of 1-3 mg / mL;

[0036] ②Take 80 mL of GO with a concentration of 2 mg / mL, add 20 mL of concentrated nitric acid (wt≥65%) while stirring gently, and continue stirring for 10-30 min to make it fully mixed;

[0037] ③The reaction solution was transferred to a 100 mL stainless steel Teflon-lined autoclave, and the reaction was sealed at 150 °C for 20 h;

[0038] ④ After the reaction, the cooled reaction solution was transferred to a 250 mL beaker, heated and evaporated to dryness in a water bath at 60-80 °C, and the resulting brown-yellow powder was NGO.

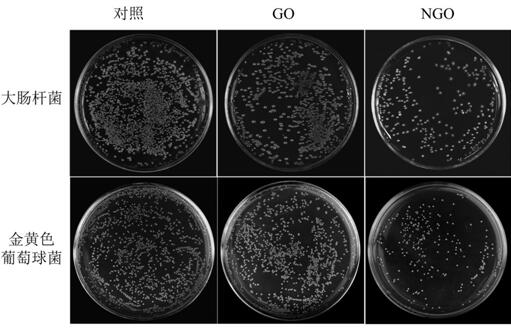

[0039] Bactericidal performance of NGO: NGO with a concentration of 30 μg / mL was effective against Escherichia coli (10 7 CFU / mL) bactericidal rate of 91.26%, against Staphylococcus aureus (10 7 CFU / mL) the bactericidal rate ...

Embodiment 3

[0041] (1) Preparation of GO: Same as Example 1;

[0042] (2) Preparation of nitrated graphene oxide (NGO)

[0043] ① Add the above GO to deionized water to obtain a GO dispersion with a concentration of 1-3 mg / mL;

[0044] ② Take 70 mL of GO with a concentration of 3 mg / mL, add 30 mL of concentrated nitric acid (wt ≥ 65%) while stirring gently, and continue stirring for 10-30 min to make it fully mixed;

[0045] ③Transfer the reaction solution to a 100 mL stainless steel Teflon-lined autoclave, and react in a sealed environment at 180°C for 15 hours;

[0046] ④ After the reaction, transfer the cooled reaction liquid to a 250 mL beaker, heat and evaporate to dryness in a water bath at 60°C-80°C, and the resulting brown-yellow powder is NGO.

[0047] Bactericidal performance of NGO: NGO with a concentration of 30 μg / mL was effective against Escherichia coli (10 7 CFU / mL) bactericidal rate of 85.32%, against Staphylococcus aureus (10 7 CFU / mL) the bactericidal rate was 70....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com