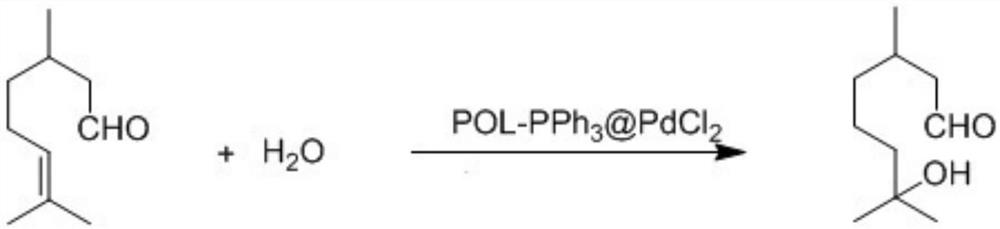

Efficient green synthesis method of hydroxycitronellal

A hydroxycitronellal, green synthesis technology, applied in the field of flavor and fragrance synthesis, can solve the problems of affecting the living environment, difficult to prepare, pollute the environment, etc., and achieve high yield and production efficiency, high yield and high selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] POL-PPh used in the present invention 3 The preparation method is as follows: 1.0g 3V-PPh 3 Dissolve in 10ml of THF, then add 25mg of azobisisobutyronitrile, mix well and transfer to a reaction kettle, react at 100°C for 24h, evaporate the solvent in vacuo, and obtain white powder POL-PPh 3 .

[0026] The 3V-PPh 3 The preparation process is as follows: 22mmol of PPh 3 Dissolve it in 30ml THF, and slowly drop it into the pre-prepared 4-vinylmagnesium bromide Grignard reagent at 0°C. After the addition is completed, continue the reaction at room temperature for 2 hours. 4 The reaction was quenched with Cl solution, extracted with excess ethyl acetate, the organic phase was washed with saturated brine, dried over anhydrous magnesium sulfate, and finally the product was purified with a silica gel column to obtain a white 3V-PPh3 solid.

Embodiment 1

[0028] A kind of efficient green synthetic method of hydroxycitronellal, comprises the steps:

[0029] (1) Catalyst preparation: 500mg POL-PPh 3 and 25mgPdCl 2 Add 25 mL into a sealed tube filled with nitrogen, then add 5 mL of anhydrous THF, react overnight at 32 ° C, filter, remove the filtrate, wash the filter residue twice with ethyl acetate and ethanol, and collect the solid to obtain 519 mg of POL-PPh 3 @PdCl 2 solid catalyst;

[0030] (2) Catalyzed synthesis reaction: weigh 200mgPOL-PPh in a 500mL round bottom flask 3 @PdCl 2 , add citronellal 4.629g (30mmol), water 2.7g (100mmol) and toluene 150mL, stir evenly, react at 200°C for 12h to obtain a reaction solution;

[0031] (3) After the reaction liquid is cooled, filter and separate the solid catalyst, then fractionate the reaction liquid through a fractionating tower, and collect the distillate at about 257° C. to obtain 3.725 g of hydroxycitronellal.

[0032] The productive rate of this example hydroxycitronell...

Embodiment 2

[0036]A kind of efficient green synthetic method of hydroxycitronellal, comprises the steps:

[0037] (1) Catalyst preparation: 500mg POL-PPh 3 and 35mgPdCl 2 Add it into a 25mL sealed tube filled with nitrogen, then add 5mL of anhydrous THF, react overnight at 35°C, filter, remove the filtrate, wash the filter residue twice with ethyl acetate and ethanol, and collect the solid to obtain 524mg of POL-PPh 3 @PdCl 2 solid catalyst;

[0038] (2) Catalytic synthesis reaction: Weigh 200mgPOL-PPh3@PdCl in a 500mL round bottom flask 2 , add 6.172g (40mmol) of citronellal, 4.05g (150mmol) of water and 160mL of toluene, stir well, and react at 180°C for 18h to obtain a reaction solution;

[0039] (3) After the reaction liquid is cooled, filter and separate the solid catalyst, then fractionate the reaction liquid through a fractionating tower, and collect the distillate at about 257° C. to obtain 4.826 g of hydroxycitronellal.

[0040] The productive rate of this example hydroxycit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com