Foamy copper/epoxy resin electronic packaging material and preparation method thereof

A technology of electronic packaging materials and epoxy resin, which is applied in the field of foamed copper/epoxy resin electronic packaging materials and its preparation, can solve the problem that the high thermal conductivity of electronic packaging materials, the small increase in thermal conductivity, and the lack of electromagnetic Shielding performance and other issues, to achieve excellent electromagnetic shielding performance, improve compression strength, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

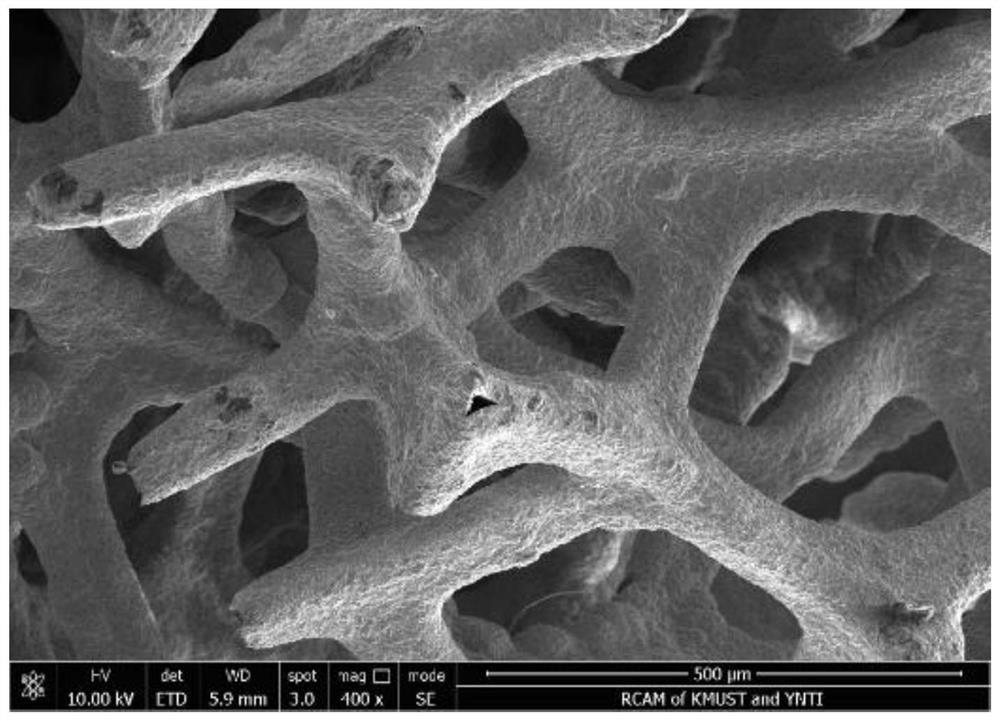

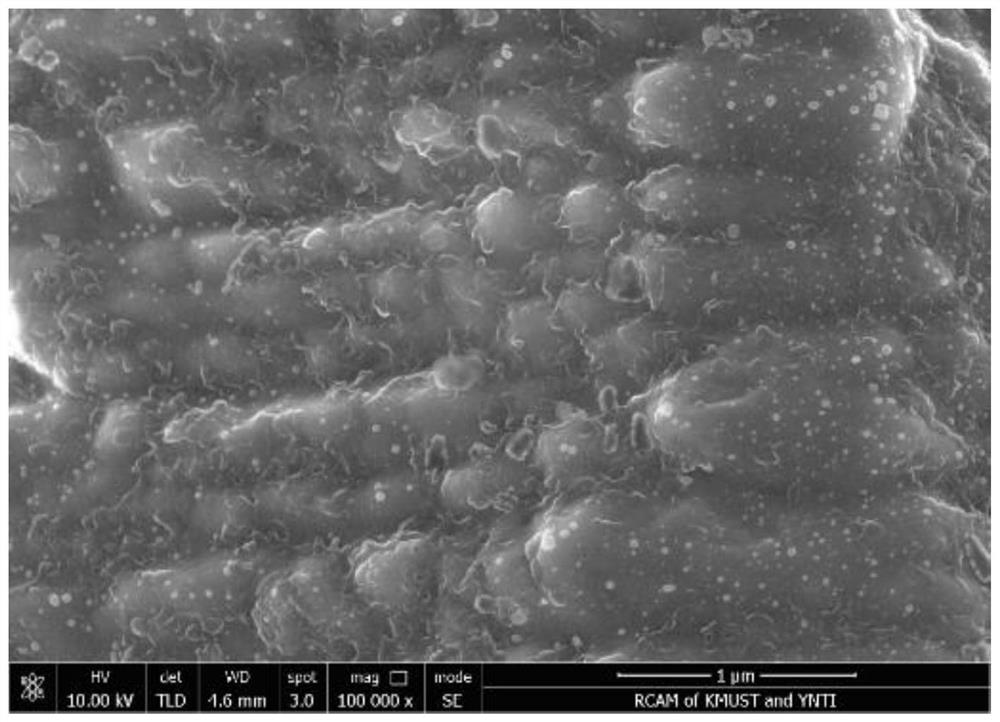

[0040] Step 1: Prepare the electroplating solution of foamed copper doped with carbon nanotubes, the electroplating solution is made of CuSO 4 ·5H 2 O, concentrated H 2 SO 4 , brightener 1-4 butynediol, surfactant polyethylene glycol and carbon nanotubes CNTs, in which CuSO 4 ·5H 2 The concentration of O is 100g / L, concentrated H 2 SO 4 The concentration of the brightener is 60g / L, the concentration of the brightener is 0.23g / L, the concentration of the surfactant is 0.7g / L, the concentration of the CNTs is 1g / L, the diameter of the carbon nanotubes is 30-80nm, and the length is less than 10μm, set the current density to 4A·dm -2 , the electroplating time is 9h, and the copper foam doped with carbon nanotubes is prepared by electrodeposition; the porosity of the copper foam doped with carbon nanotubes is 98%, and the volume fraction of carbon nanotubes in the copper foam doped with carbon nanotubes is 0.579%.

[0041]Step 2: prepare curing agent polyacrylamide and bisp...

Embodiment 2

[0045] The difference from Example 1 is that the mass ratio of SiC and epoxy resin in step 2 is 3.2:1, and the particle size of SiC is 50 μm.

[0046] Results: The thermal conductivity of the SiC-containing epoxy resin prepared in step 2 was 4.3W / (m·K), and the electromagnetic shielding performance reached 7.5dB at the electromagnetic wave frequency of 8-12GHz. The massfraction of SiC in the prepared copper foam / epoxy resin electronic packaging material is 40wt%; the thermal conductivity of the prepared foam copper / epoxy resin electronic packaging material is 47.2W / (m K), electromagnetic shielding The performance reaches 44.3dB when the electromagnetic wave frequency is 8-12GHz.

Embodiment 3

[0048] The difference from Example 1 is that the mass ratio of SiC and epoxy resin in step 2 is 3.4:1, and the particle size of SiC is 60 μm.

[0049] Results: The thermal conductivity of the SiC-containing epoxy resin prepared in step 2 is 5.6W / (m·K). The electromagnetic shielding performance reaches 8.7dB at the frequency of electromagnetic waves of 8-12GHz. The mass fraction of SiC in the prepared foamed copper / epoxy resin electronic packaging material is 50wt%; the thermal conductivity of the prepared foamed copper / epoxy resin electronic packaging material is 47.2W / (m K), electromagnetic shielding The performance reaches 49.5dB when the electromagnetic wave frequency is 8-12GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com