Water-based organic silicon modified fluorocarbon wind turbine blade coating and preparation method thereof

A technology for modifying fluorocarbon and wind turbine blades, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of environmental pollution, waste of energy costs, etc., and achieve good chemical resistance, hard and wear-resistant coating performance, Good heat and humidity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

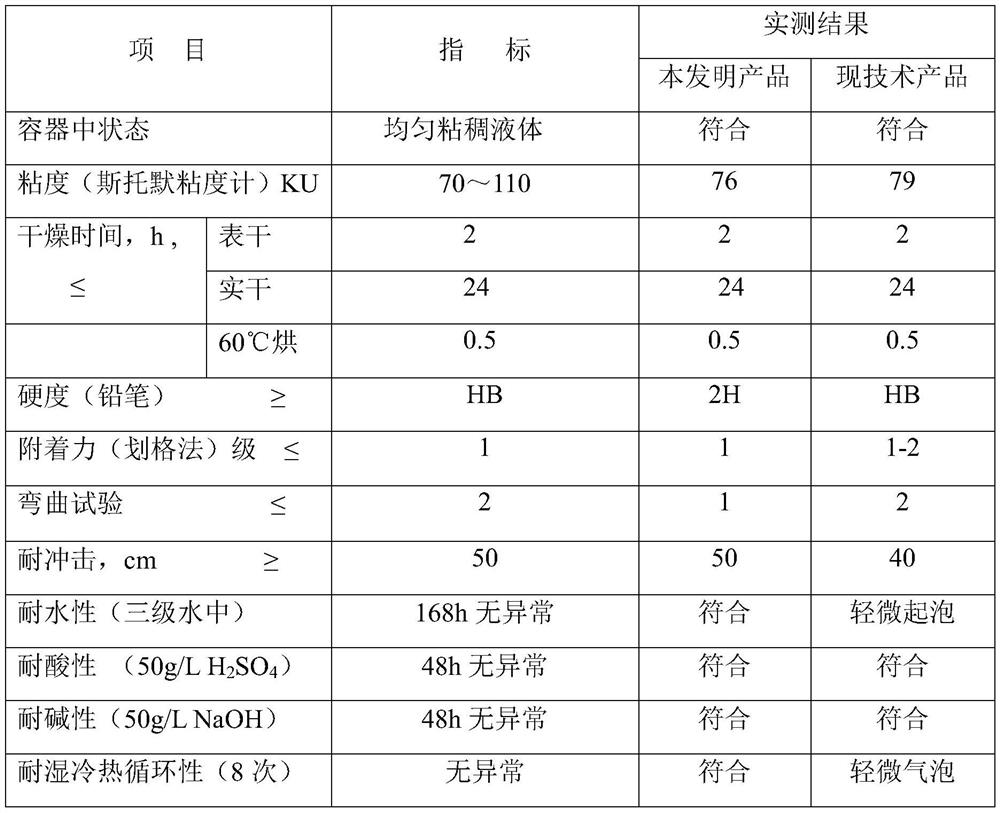

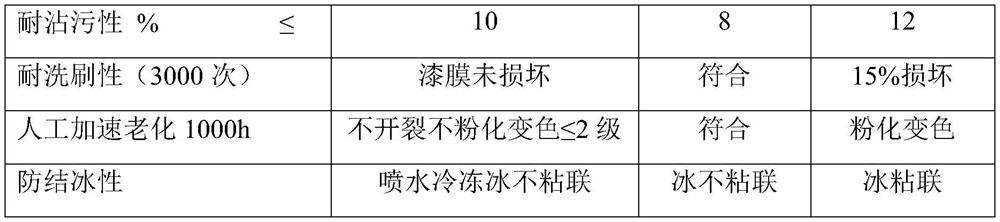

Examples

Embodiment 1

[0059] Water-based organosilicon modified fluorocarbon wind power blade coating main paint, including the following raw materials in parts by weight: water-based fluorocarbon resin (model DF-M105A) 57kg, polyether modified polydimethylsiloxane (model WE-D9750R) 8kg, SN9750 preservative 0.1kg, SN-5780 defoamer 0.3kg, 2105-3SiW substrate wetting agent 0.5kg, SN3760 leveling agent 0.5kg, SN-7520 adhesion promoter 1kg, water-based industrial color paste 30kg, Thickener 0.3kg, SN-9730pH regulator 0.1kg, deionized water 2.3kg. The thickener in this example is made by mixing Gel0434 thickener and Gel0620 thickener, and the mass ratio of Gel0434 thickener to Gel0620 thickener is 1:1.

[0060] The preparation method of main paint comprises the following steps:

[0061] (1) Add water-based fluorocarbon resin, preservative, defoamer, substrate wetting agent, leveling agent, and adhesion promoter into the mixing tank according to the proportion of weight components and mix them, then add...

Embodiment 2

[0068] Water-based organosilicon-modified fluorocarbon wind power blade coating main paint, including the following raw materials in parts by weight: 60 kg of water-based fluorocarbon resin, 5 kg of polyether modified polydimethylsiloxane, 0.1 kg of SN9750 preservative, 0.1 kg of SN-5780 disinfectant Foaming agent 0.3kg, 2105-3SiW substrate wetting agent 0.5kg, SN3760 leveling agent 0.5kg, SN-7520 adhesion promoter 1kg, water-based industrial color paste 30kg, thickener 0.2kg, SN-9730pH regulator 0.1 kg, deionized water 2.3kg. The thickener in this example is made by mixing Gel0434 thickener and Gel0620 thickener, and the mass ratio of Gel0434 thickener to Gel0620 thickener is 1:1.

[0069] The preparation method of main paint comprises the following steps:

[0070] (1) Add water-based fluorocarbon resin, preservative, defoamer, substrate wetting agent, leveling agent, and adhesion promoter into the mixing tank according to the proportion of weight components and mix them, th...

Embodiment 3

[0076] Water-based organosilicon modified fluorocarbon wind power blade coating main paint, including the following raw materials in parts by weight: 58.5 kg of water-based fluorocarbon resin, 6.5 kg of polyether modified polydimethylsiloxane, 0.1 kg of SN9750 preservative, SN- 5780 defoamer 0.3kg, 2105-3SiW substrate wetting agent 0.5kg, SN3760 leveling agent 0.5kg, SN-7520 adhesion promoter 1kg, water-based industrial color paste 30kg, thickener 0.2kg, SN-9730pH adjustment Agent 0.1kg, deionized water 2.3kg. In this embodiment, the thickener is formed by mixing the Gel0434 thickener and the Gel0620 thickener, and the mass ratio of the Gel0434 thickener to the Gel0620 thickener is 1 / 1.

[0077] The preparation method of main paint comprises the following steps:

[0078] (1) Add water-based fluorocarbon resin, preservative, defoamer, substrate wetting agent, leveling agent, and adhesion promoter into the mixing tank according to the proportion of weight components and mix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com