A two-dimensional semiconductor material snse 2 Single crystal preparation method

A two-dimensional semiconductor and single crystal technology, applied in the field of two-dimensional materials, can solve the problems of limited development, unavailability, high quality, etc., and achieve the effect of simple and easy preparation process, simple equipment, and improved preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

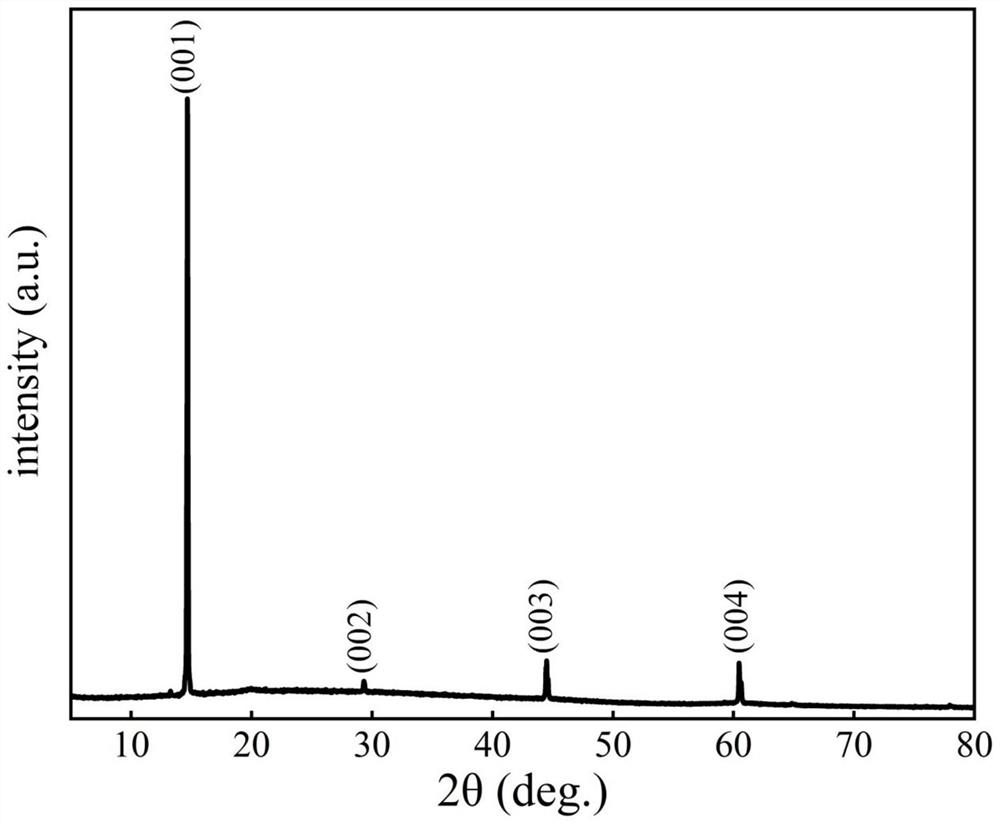

[0031] A method of chemical vapor transport (CVT) based on the preparation of sheet-like easy-to-exfoliate two-dimensional SnSe 2 Single crystal method, the steps are as follows:

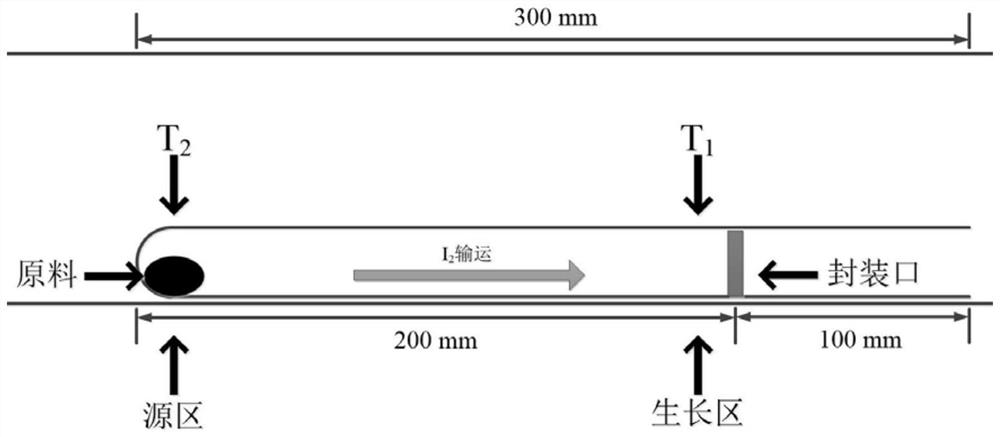

[0032] Step (1), according to the molar ratio of Se powder and Sn powder is 2:1, weigh elemental selenium powder and elemental tin powder, the total mass is 1g; according to the stickiness on weighing paper, put Sn powder and Se powder into Mortar, grind in the mortar for 10-15min until the color is uniform gray-black; through the paper cylinder channel, the uniformly mixed powder sample is transported to the quartz tube (quartz tube size: length 300mm, inner diameter 25mm, seal The closed end (100mm away from the quartz nozzle) (can be called the source area);

[0033] Add an appropriate amount of iodine particles into the quartz tube as a transfer agent. Generally, the amount of iodine used in 1g of sample is 50 mg. Also, iodine particles are placed in the closed end of the quartz tube; since iod...

Embodiment 2

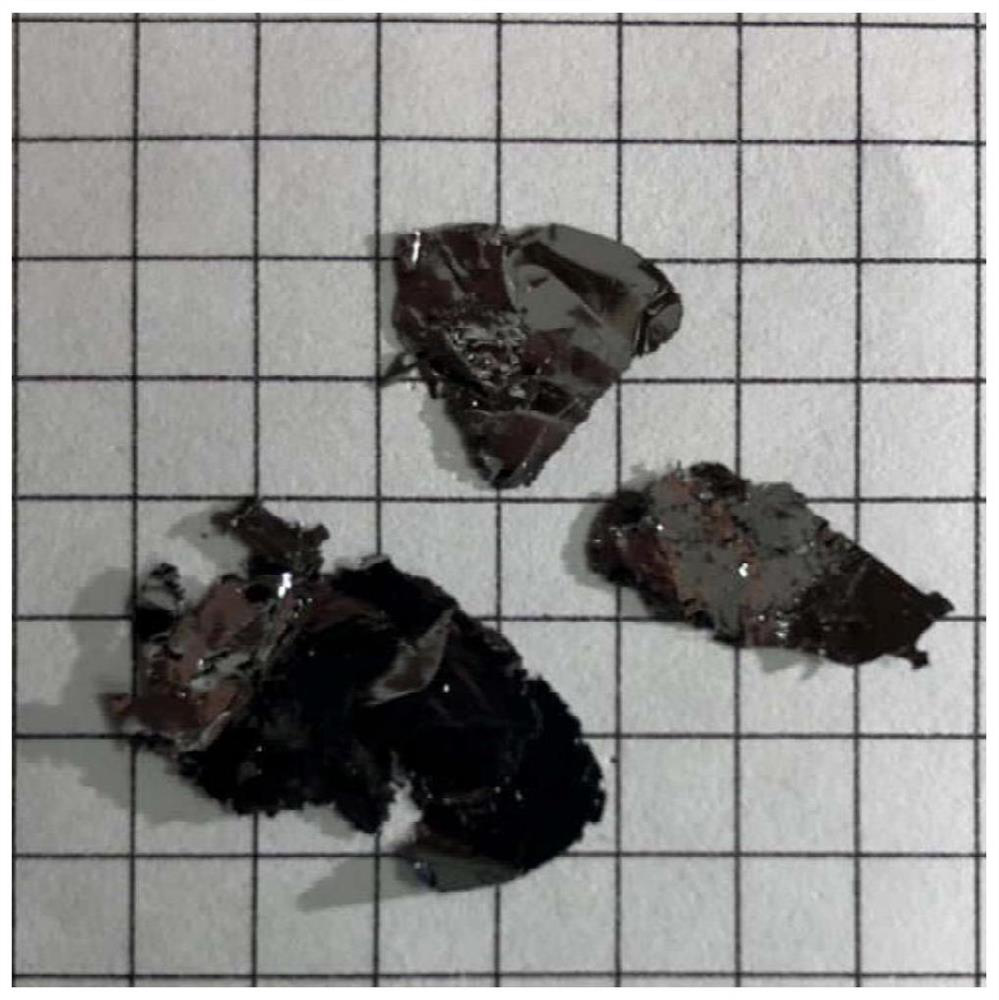

[0041] Referring to the method of Example 1, only adjust step (2) The temperature difference between the high temperature zone and the low temperature zone in the growth stage and cooling stage is maintained at 20°C, and the temperature in the low temperature zone is kept at 550°C. This embodiment can also make SnSe 2 single crystal (see Figure 5 ).

[0042] With the SnSe that embodiment 1 makes 2 Compared with single crystal, the present example SnSe 2 The area of the single crystal is relatively small, and the surface is not as good as that of the SnSe prepared in Example 1. 2 Single crystal flat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com