BaSO4-doped negative electrode material of sodium ion battery and preparation method thereof

A technology of sodium ion battery and negative electrode material, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of insufficient cycle performance and rate performance of negative electrode materials of sodium ion battery, and improve the initial capacity, cycle stability, and preparation cost. Low, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a doped BaSO 4 A negative electrode material for a sodium ion battery and a preparation method thereof, comprising the following preparation steps:

[0035] (1) One-step hydrothermal method to prepare SnO 2 Materials: Use tin source, dispersant and NaOH as raw materials for hydrothermal reaction, wherein the molar ratio of tin source to NaOH is 1:10-15, and the volume ratio of dispersant to NaOH is 1:1-1.5. After the reaction, centrifuge to collect the precipitate. SnO obtained after drying 2 material precursors;

[0036] The tin source is one or more of stannous chloride, tin tetrachloride, sodium thiostannate; the dispersant is one or more of PEG-400, PVP, DMF; the concentration of NaOH is 1~ 2mol / L; the hydrothermal reaction temperature is 120-200°C, and the reaction time is 10-24h.

[0037] (2) SnO 2 The material precursor is dissolved in deionized water, slowly adding dilute sulfuric acid solution and Ba(OH) 2 solution, magnetic stirrin...

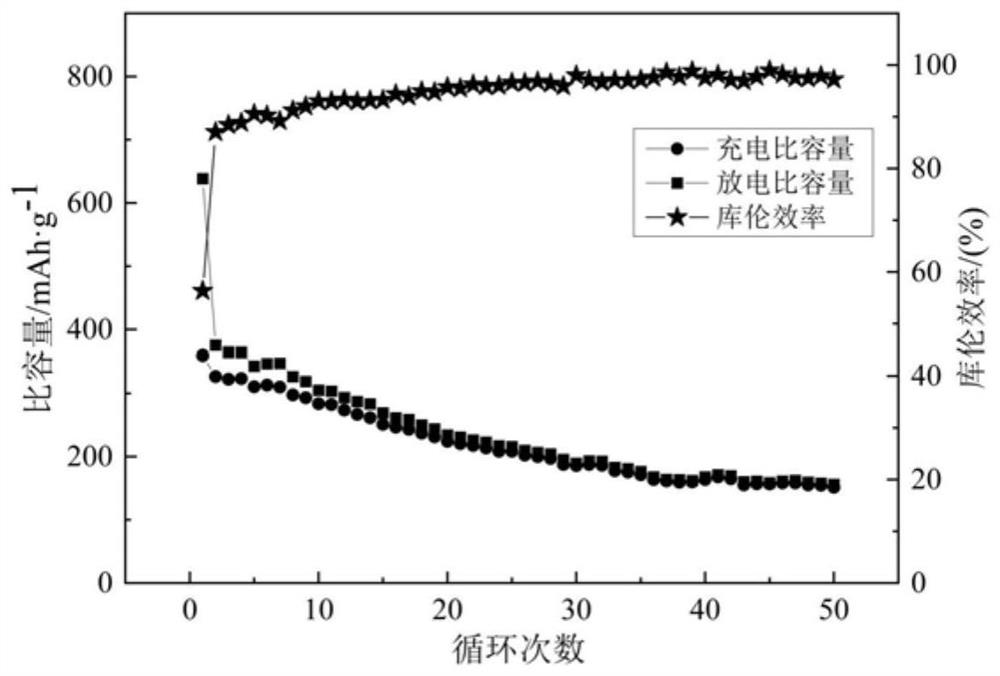

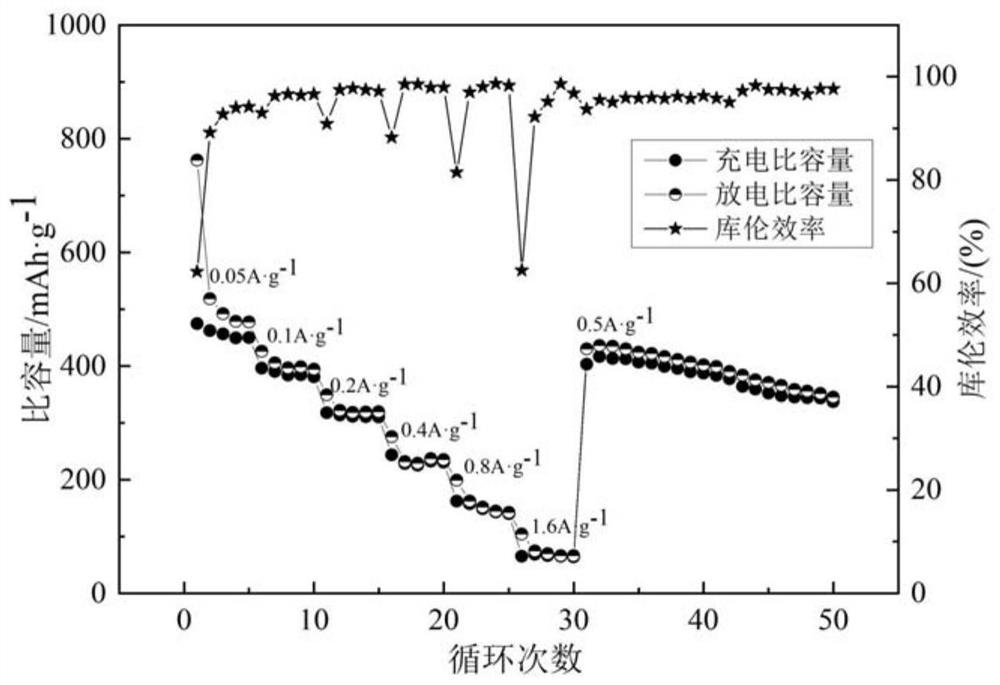

Embodiment 1

[0051] ①Using crystalline tin tetrachloride, N,N-dimethylformamide and sodium hydroxide as raw materials, weigh 2mmol SnCl 4 ·5H 2 O and 10ml of DMF were dissolved in 10ml of distilled water, and 10ml of NaOH solution with a concentration of 2mol / L was added dropwise with stirring. Stir the solution evenly and transfer it into the reactor. After hydrothermal reaction at 160°C for 15 hours, wash the precipitate with distilled water and absolute ethanol three times, and dry at 60°C for 12 hours to obtain white SnO 2 Precursor.

[0052] ② Take 5g SnO 2 Dissolve the powder in 50ml deionized water, add 5ml 0.5mol / L Ba(OH) to it under magnetic stirring 2 The prepared solution and 7.5ml 0.5mol / L dilute sulfuric acid solution were magnetically stirred at room temperature for 1 hour, and then the resulting solution was washed with distilled water and absolute ethanol three times to achieve solid-liquid separation, and then placed in a drying oven at 60°C for 12 hours. , Grind the d...

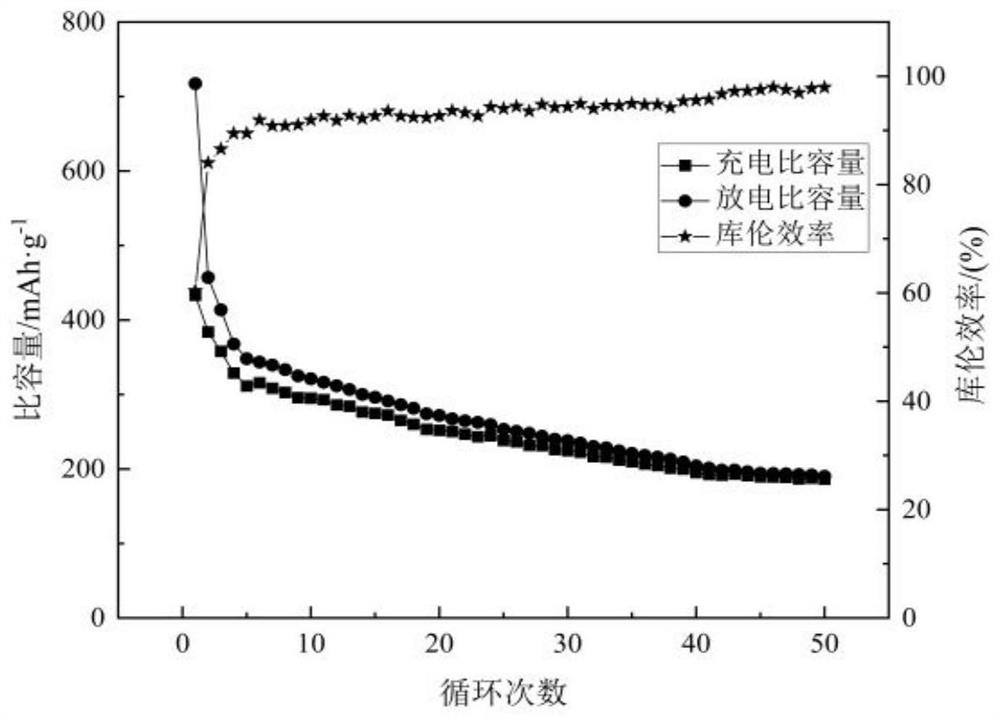

Embodiment 2

[0058] ①Using crystalline tin tetrachloride, N,N-dimethylformamide and sodium hydroxide as raw materials, weigh 2mmol SnCl 4 ·5H 2 O and 10ml of DMF were dissolved in 10ml of distilled water, and 10ml of NaOH solution with a concentration of 2mol / L was added dropwise with stirring. Stir the solution evenly and transfer it into the reactor. After hydrothermal reaction at 160°C for 15 hours, wash the precipitate with distilled water and absolute ethanol three times, and dry at 60°C for 12 hours to obtain white SnO 2 Precursor.

[0059] ② Take 5g SnO 2 Dissolve the powder in 50ml deionized water, add 3.5ml 0.5mol / LBa(OH) to it under magnetic stirring 2 The prepared solution and 10ml of 0.5mol / L dilute sulfuric acid solution were magnetically stirred at room temperature for 1 hour, and the resulting solution was washed with distilled water and absolute ethanol three times to achieve solid-liquid separation, and then placed in a drying oven at 60°C for 12 hours. Grind the dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com