Organic framework copolymer supported porous ion conducting membrane as well as preparation and application of porous ion conducting membrane

A technology of ion-conducting membranes and organic frameworks, which is applied in the application field of such membranes in flow batteries, can solve the problems of large pore size and low Coulombic efficiency of porous ion-conducting membranes, achieve high Coulombic efficiency and voltage efficiency, and avoid membrane Reduced ion conductivity, widening the effect of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

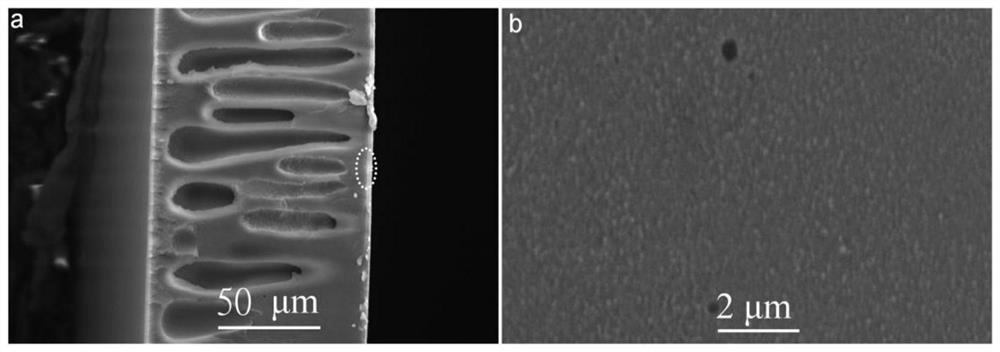

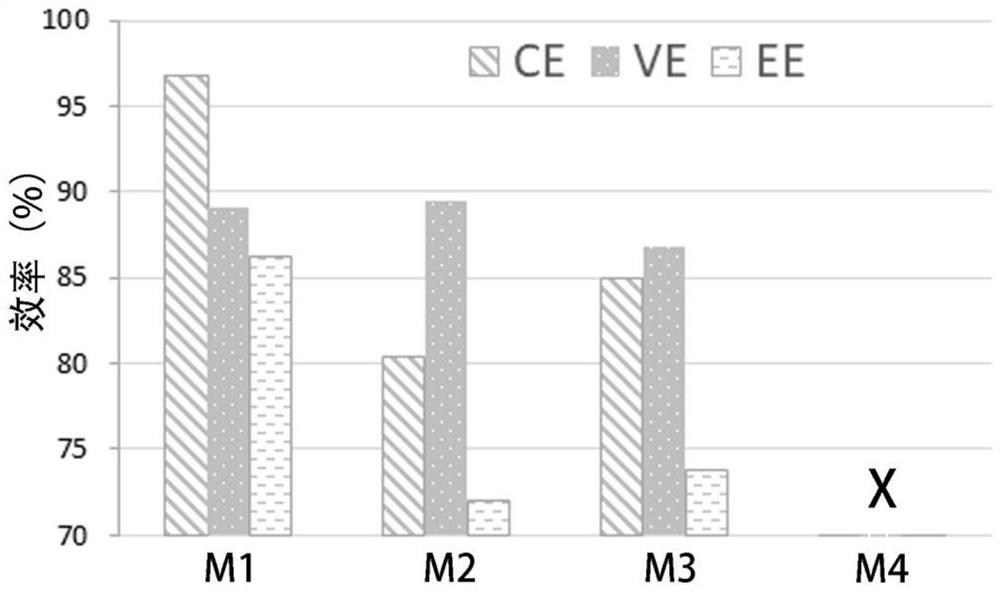

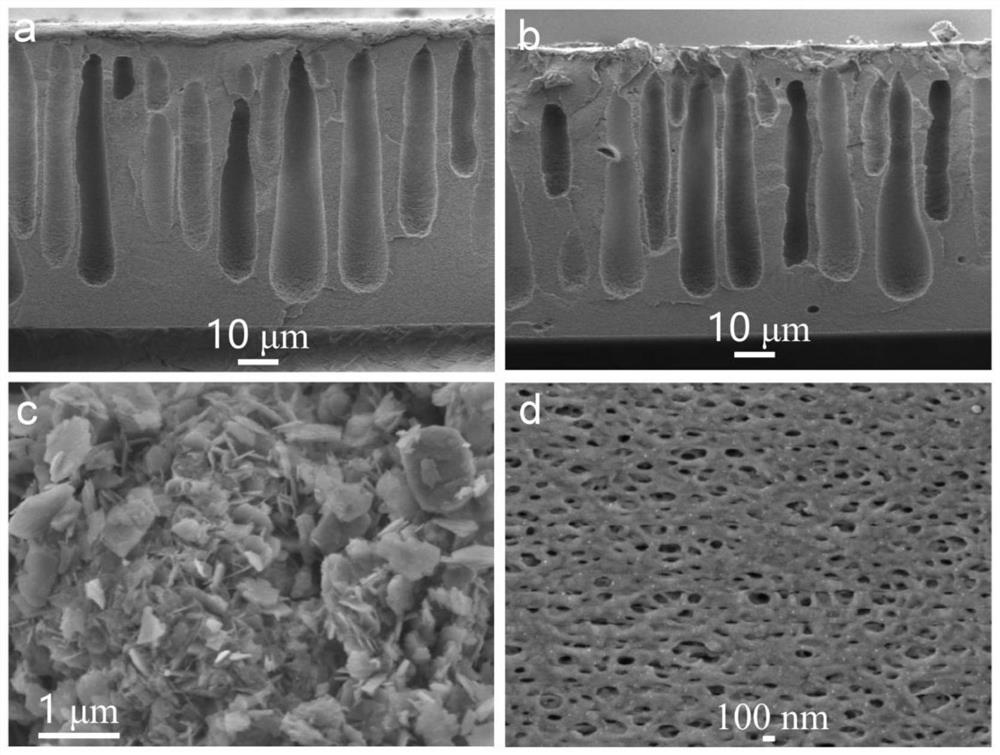

Embodiment 1

[0032]Using PES / (PVP+imidazole) as the base material, dissolve PES / (PVP+imidazole) in DMAC solvent to obtain a blend solution with a mass concentration of 30%, wherein the mass ratio of PES to PVP is 9:1, and the mass ratio of PVP to imidazole 1:1; pour the above blended solution on a clean and flat glass plate, volatilize the solvent for 10s under 20% humidity, and then immerse it as a whole in an aqueous solution containing 3wt% mass fraction of zinc chloride for 700s to form During the membrane process, imidazole in the casting solution and zinc chloride in the non-solvent generate ZIF in situ in the membrane, and a PES-(PVP+ZIF) porous ion-conducting membrane with a thickness of ~75 μm is prepared at 25°C (using M2 express). From image 3 a It can be seen that the cross-section of the prepared membrane has an obvious finger-like pore structure, which further enlarges the cross-sectional cortex structure ( image 3 c), it can be seen that ZIF (thickness ~ 80nm) with obvio...

Embodiment 2

[0034] Using PES / (PVP+imidazole) as the base material, dissolve PES / (PVP+imidazole) in DMAC solvent to obtain a blend solution with a mass concentration of 30%, wherein the mass ratio of PES to PVP is 9:1, and the mass ratio of PVP to imidazole 1:1; pour the above blended solution on a clean and flat glass plate, volatilize the solvent for 10s under 20% humidity, and then immerse it as a whole in a zinc chloride solution containing 3wt% mass fraction for 700s to form a film During the process, imidazole in the casting solution and zinc chloride in the non-solvent generate ZIF in situ in the membrane, and a PES-(PVP+ZIF) porous ion-conducting membrane with a thickness of ~75 μm is prepared at 25°C. After soaking the PES-(PVP+ZIF) porous ion-conducting membrane prepared above in ethanol for 30 minutes, dry it at room temperature for 60 minutes. During the drying process, the ZIF in the membrane pores can maintain its pore structure and remain unchanged, thereby Prevent the colla...

Embodiment 3

[0037] Using PES / imidazole as the base material, dissolve PES / imidazole in DMAC solvent to obtain a blend solution with a mass concentration of 26%, wherein the mass ratio of PES to imidazole is 8:2, pour the above blend solution on a clean and flat glass On the board, volatilize the solvent for 10s under 20% humidity, and then immerse it as a whole in a zinc chloride solution containing 3wt% mass fraction for 700s. Zinc generates ZIF in situ in the membrane, and a PES-ZIF porous ion-conducting membrane with a thickness of ~63 μm is prepared at 25 °C. The prepared porous ion-conducting membrane was soaked in ethanol for 30 minutes, and then dried at room temperature for 60 minutes. During the drying process, the ZIF in the membrane pores could maintain its pore structure, thus preventing the membrane pore structure from collapsing. Immerse it in 10wt% dilute hydrochloric acid solution to remove the ZIF generated in the membrane to obtain a ZIF-free PES porous ion-conducting me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com