Device and method for spinning crystallization of nervonic acid grease

A crystallization device, a technology of nervonic acid, applied in the directions of crystallization separation, solution crystallization, separation method, etc., can solve the problems of destroying the crystal lattice, uneven cooling, and increasing the load of the filtration process, so as to reduce the load, increase the cooling area, The effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

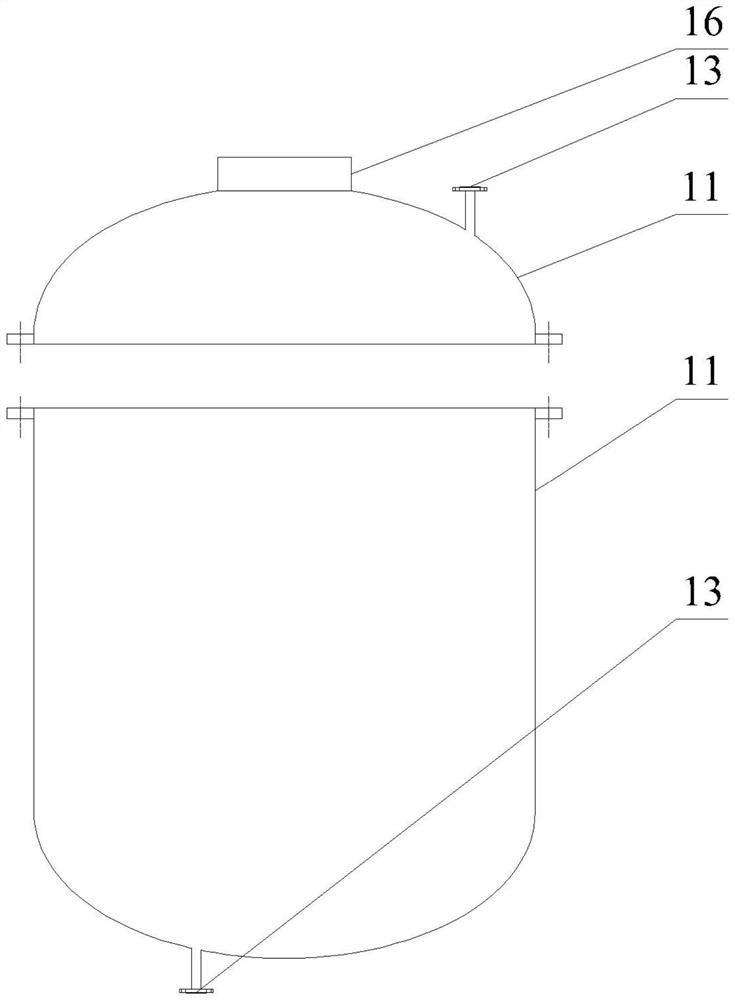

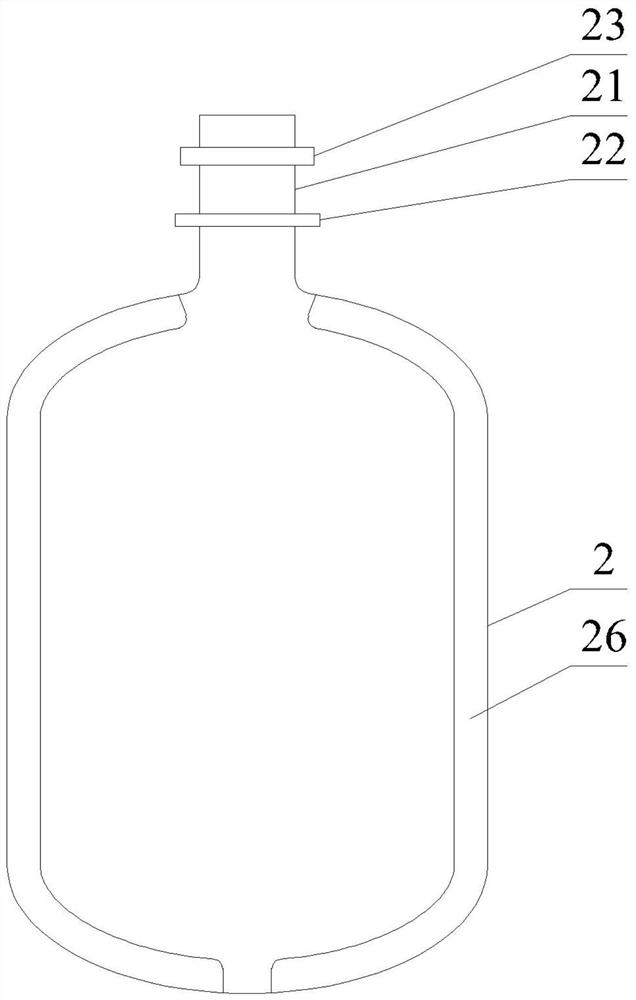

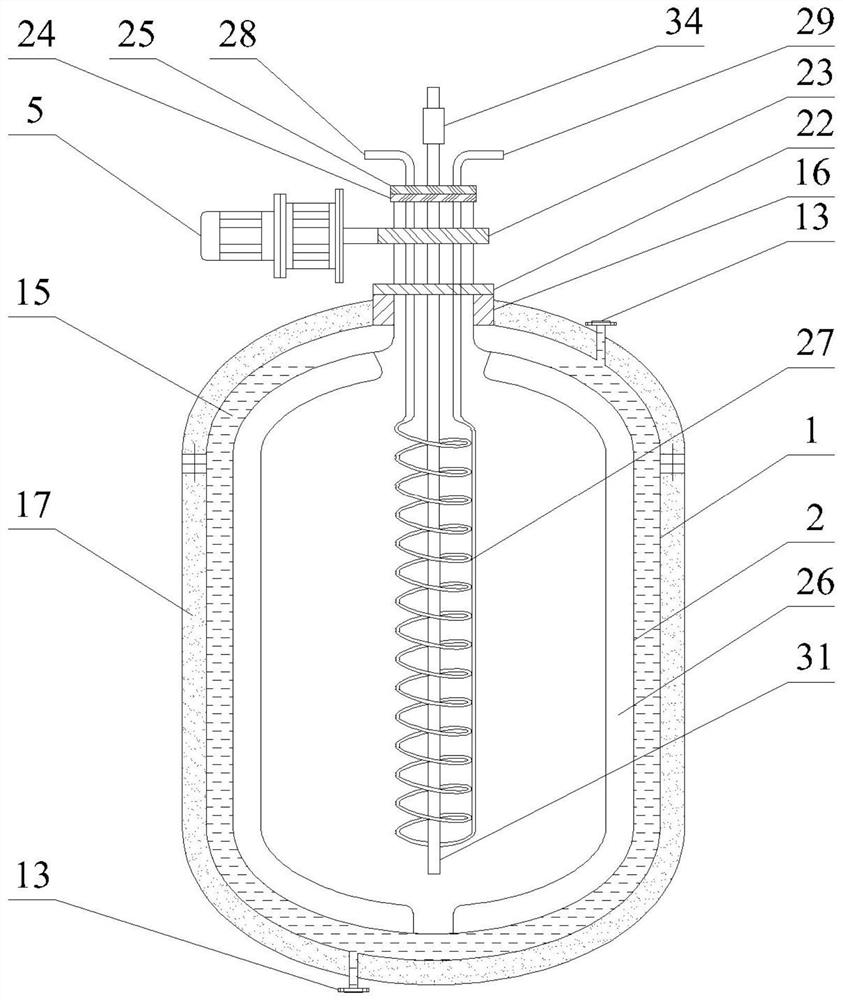

[0034] Such as figure 1 , 2, Shown in 3, a kind of nervonic acid grease spin crystallization device, comprises crystallization tank 22, cooling tank 1, power unit 5, cooling coil 27. The crystallization tank 22 is set in the cooling tank 1, the neck 21 of the crystallization tank protrudes from the top of the cooling tank 1, and a cavity is formed between the crystallization tank 2 and the cooling tank 1; the cooling tank 1 is composed of a tank body 11 and a head 12 The tank body 11 is flexibly connected with the head 12, the bottom of the cooling tank 1 is provided with a coolant inlet 13, the top of the cooling tank 1 is provided with a coolant outlet 14, and the outside of the cooling tank 1 is provided with an insulating material 17. The top opening of the cooling tank 1 is provided with a bearing 16 at the opening, and the crystallization tank neck 21 protrudes from the bearing 16; the crystallization tank neck 21 is provided with a bearing snap ring 22, a transmission ...

Embodiment 2

[0043] Such as figure 1 , 2 , 4, 5, and 6, a nervonic acid oil spin crystallization device includes a crystallization tank 2, a cooling tank 1, a power unit 5, and a cooling coil 27. The crystallization tank 2 is set in the cooling tank 1, the neck 21 of the crystallization tank protrudes from the top of the cooling tank 1, and a cavity is formed between the crystallization tank 2 and the cooling tank 1; the cooling tank 1 is composed of a tank body 11 and a head 12 The tank body 11 is flexibly connected with the head 12, the bottom of the cooling tank 1 is provided with a coolant inlet 13, the top of the cooling tank 1 is provided with a coolant outlet 14, and the outside of the cooling tank 1 is provided with an insulating material 17. The top opening of the cooling tank 1 is provided with a bearing 16 at the opening, and the crystallization tank neck 21 protrudes from the bearing 16; the crystallization tank neck 21 is provided with a bearing snap ring 22, a transmission g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com