Ruthenium-based hydrogenation catalyst, ruthenium-based hydrogenation catalyst aqueous solution, preparation method and application thereof

A technology of hydrogenation catalyst and aqueous solution, which is applied in the direction of catalyst, hydrogenation hydrocarbon, metal/metal oxide/metal hydroxide catalyst, etc. Difficulties and other problems, to achieve the effect of strong ability to resist fluctuations in process conditions, long service life, and simple regeneration steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

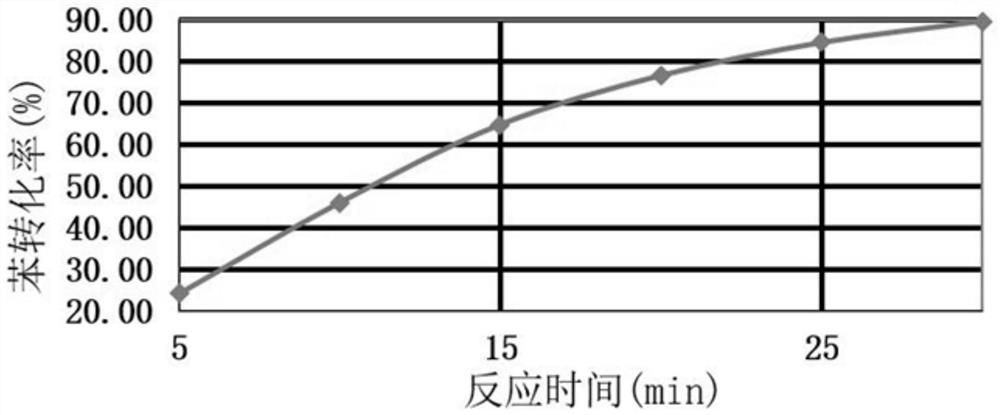

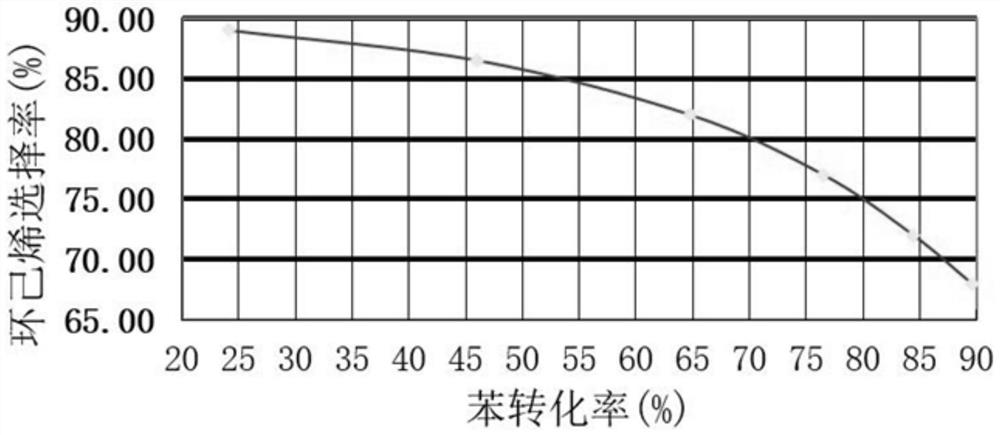

Embodiment 1

[0044]This embodiment provides an aqueous solution of a ruthenium-based hydrogenation catalyst, including 4.5 g of ruthenium as an active component, 0.43 g of zinc as a first auxiliary agent, and 0.001 g of platinum as a second auxiliary agent;

[0045] The preparation method of above-mentioned ruthenium-based hydrogenation catalyst aqueous solution, comprises the steps:

[0046] 1) adding ruthenium chloride, zinc sulfate and platinum chloride to water at room temperature to prepare a metal salt solution, the mass fraction of metal ruthenium in the metal salt solution is 4.5%, and the mass fraction of metal zinc is 0.43%, The mass fraction of metallic platinum is 0.001%;

[0047] 2) 100g of the above-mentioned metal salt solution is added in the reactor, then 100g of sodium hydroxide aqueous solution is added in the metal salt solution (the mass fraction of sodium hydroxide in the sodium hydroxide aqueous solution is 10%), and the pH value of the mixed solution is controlled t...

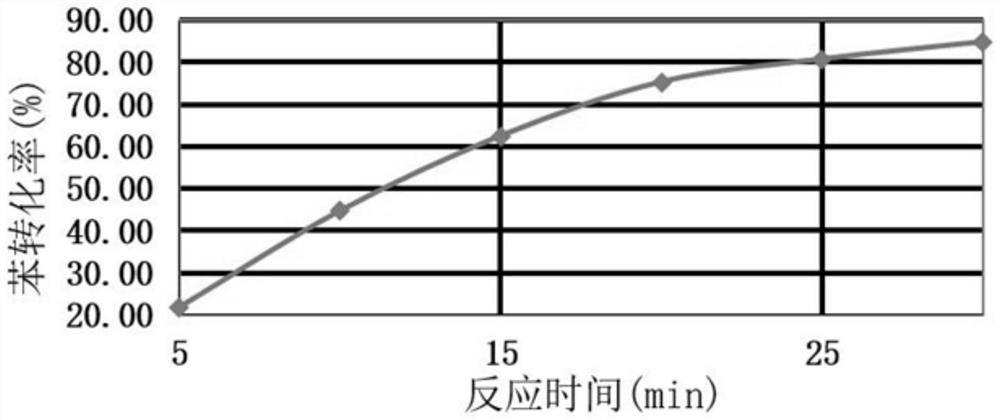

Embodiment 2

[0067] This embodiment provides an aqueous solution of a ruthenium-based hydrogenation catalyst, including 3.8 g of ruthenium as an active component, 0.48 g of zinc as a first auxiliary agent, and 0.001 g of platinum as a second auxiliary agent;

[0068] The preparation method of above-mentioned ruthenium-based hydrogenation catalyst aqueous solution, comprises the steps:

[0069] 1) At room temperature, 8.62g ruthenium chloride, 1.185g zinc sulfate and 0.0017g platinum chloride were added to 90.19g water to prepare a metal salt solution. The mass fraction of metal ruthenium in the metal salt solution was 3.8%. The mass fraction of zinc is 0.48%, and the mass fraction of metallic platinum is 0.001%;

[0070] 2) the above-mentioned metal salt solution is added in the reactor, and then 85g of sodium hydroxide aqueous solution (the mass fraction of sodium hydroxide in the sodium hydroxide aqueous solution is 12%) is added in the metal salt solution, and the pH value of the mixed ...

Embodiment 3

[0077] This embodiment provides an aqueous solution of a ruthenium-based hydrogenation catalyst, including 4.2 g of ruthenium as an active component, 0.4 g of zinc as a first auxiliary agent, and 0.0014 g of platinum as a second auxiliary agent;

[0078] The preparation method of above-mentioned ruthenium-based hydrogenation catalyst aqueous solution, comprises the steps:

[0079] 1) adding ruthenium chloride, zinc sulfate and platinum chloride to water at room temperature to prepare a metal salt solution, the mass fraction of metal ruthenium in the metal salt solution is 4.2%, and the mass fraction of metal zinc is 0.4%, The mass fraction of metallic platinum is 0.0014%;

[0080] 2) 100g of the above-mentioned metal salt solution is added into the reactor, then 100g of sodium hydroxide aqueous solution is added to the metal salt solution (the mass fraction of sodium hydroxide in the sodium hydroxide aqueous solution is 10%), and the pH value of the mixed solution is controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com