Novel biodegradable frozen product packaging film bag

A biodegradable and frozen product technology, applied in the direction of biological packaging, sustainable packaging, packaging, etc., can solve the problems of adverse impacts of human sustainable development, pollution of groundwater, marine soil, etc. Degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

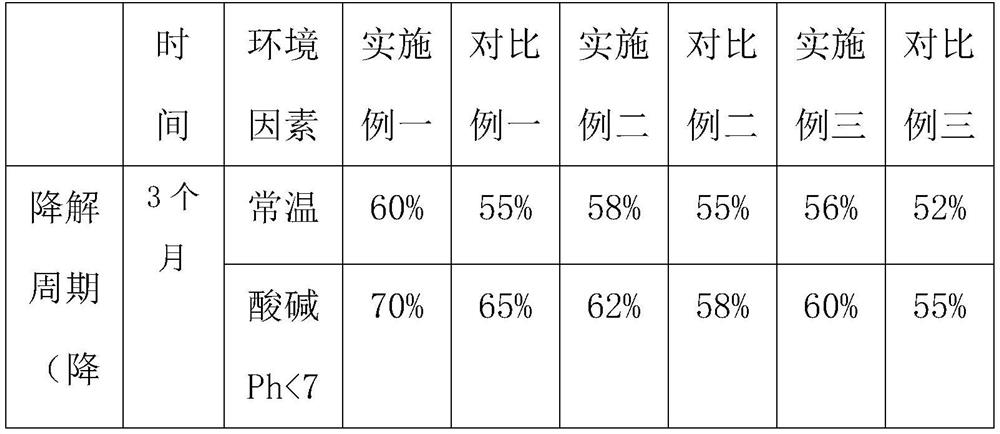

Examples

Embodiment 1

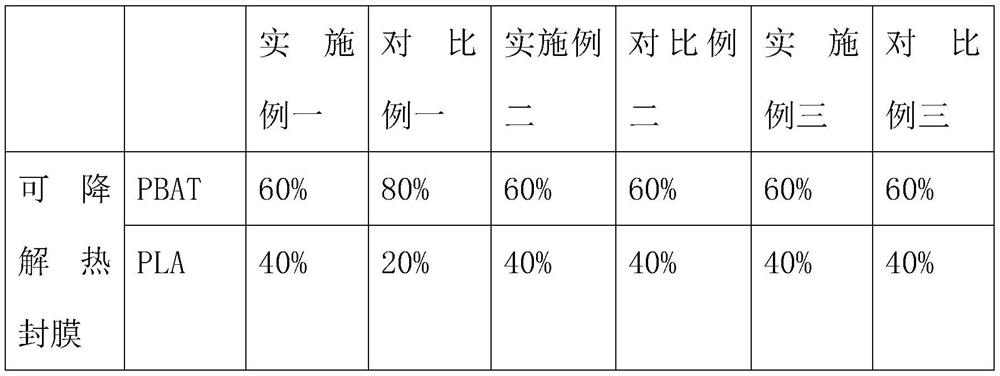

[0036] A new type of biodegradable frozen product packaging film bag, the packaging film bag is composed of a degradable heat-sealing film on the outer layer and a cellulose film on the inner layer without solvents:

[0037] The degradable heat-sealing film is composed of 60% by mass of PBAT and 40% by mass of PLA;

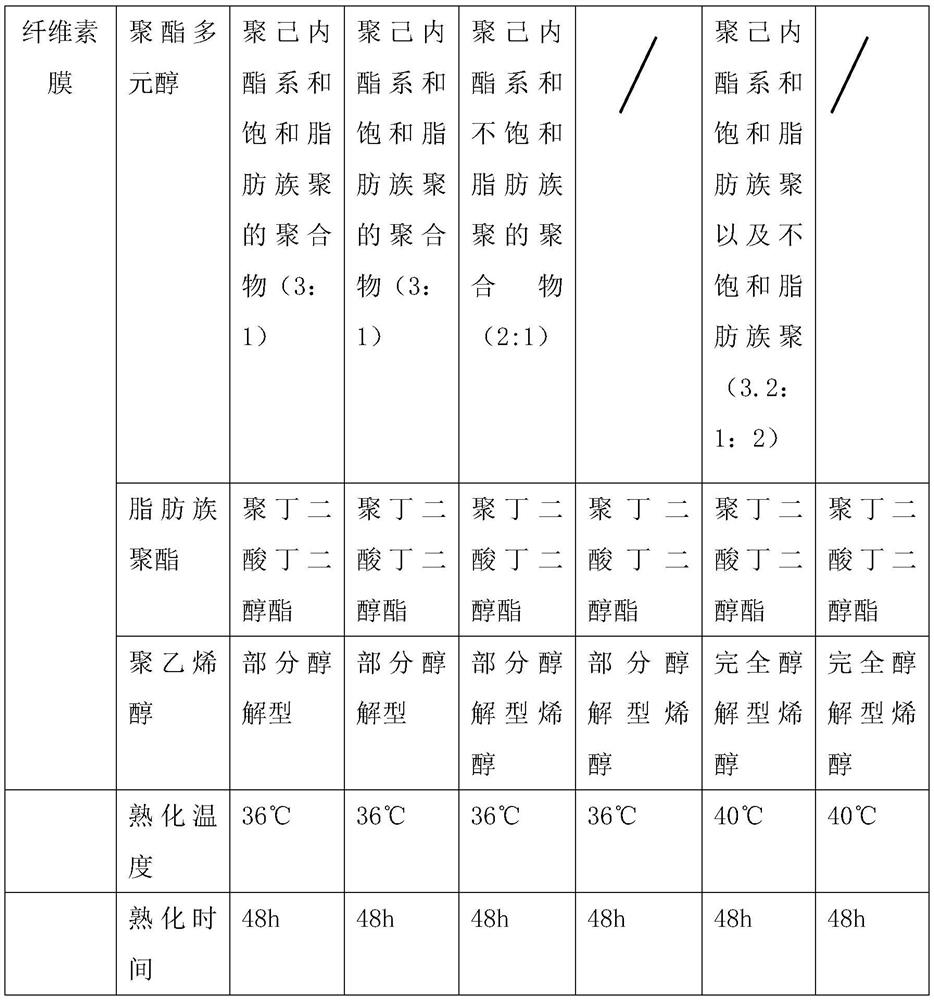

[0038] The cellulose film is made by polymerizing 30% polyester polyol, 50% aliphatic polyester and 20% polyvinyl alcohol;

[0039] Wherein, the polyester polyol is a polymer of polycaprolactone-based polyester polyol and saturated aliphatic polyester polyol, and polycaprolactone-based polyester polyol:aliphatic polyester polyol=3:1;

[0040] Aliphatic polyesters are selected from polybutylene succinates.

[0041] The polyvinyl alcohol is a partially alcoholysed enol, and the polyvinyl alcohol is polyvinyl alcohol 17-88.

[0042] A preparation method of a novel biodegradable frozen product packaging film bag, comprising the following steps:

[0043] S1, take th...

Embodiment 2

[0072] A new type of biodegradable frozen product packaging film bag, the packaging film bag is composed of a degradable heat-sealing film on the outer layer and a cellulose film on the inner layer without solvents:

[0073] The degradable heat-sealing film is composed of 60% by mass of PBAT and 40% by mass of PLA;

[0074] The cellulose film is made by polymerizing 30% polyester polyol, 50% aliphatic polyester and 20% polyvinyl alcohol;

[0075] Among them, polyester polyol is a polymer of polycaprolactone-based polyester polyol and unsaturated aliphatic polyester polyol, and polycaprolactone-based polyester polyol: a polymer of unsaturated aliphatic polyester polyol =2:1;

[0076] Aliphatic polyesters are selected from polybutylene succinates.

[0077] The polyvinyl alcohol is a partially alcoholysed enol, and the polyvinyl alcohol is polyvinyl alcohol 17-88.

[0078] A preparation method of a novel biodegradable frozen product packaging film bag, comprising the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com