Preparation method of lead lanthanum zirconate titanate piezoelectric ceramic formed by thermocuring powder injection molding

A powder injection molding, lead lanthanum zirconate titanate technology, which is applied in the field of preparation of lead lanthanum zirconate titanate piezoelectric ceramics, can solve the problem that the strength of the ceramic injection blank is not very high, and can overcome the problems of low molding efficiency, high density, and the high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

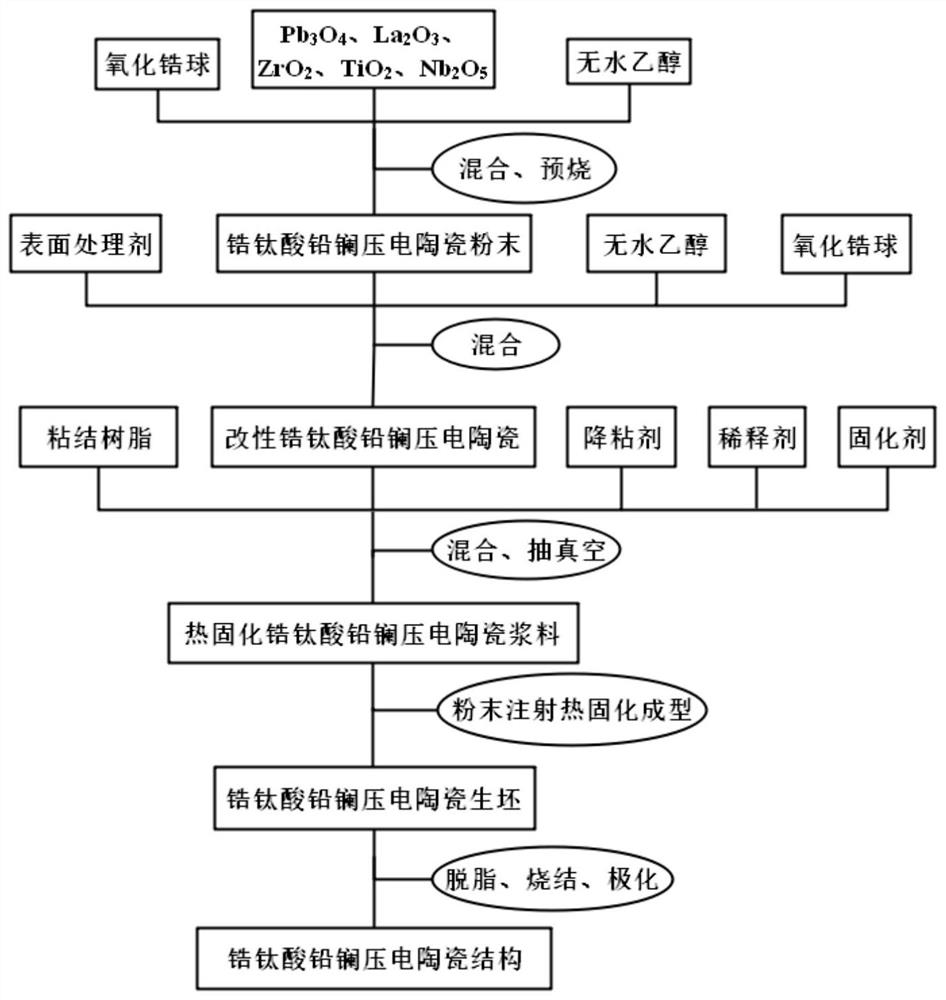

Method used

Image

Examples

Embodiment 1

[0032] The preparation formula is Pb 0.91 La 0.06 (Zr 0.58 Ti 0.42 ) 0.975 Nb 0.02 o 3 The lead lanthanum zirconate titanate piezoelectric ceramic powder, the Pb 3 o 4 (64.4%), La 2 o 3 (3.08%), ZrO 2 (21.9%), TiO 2 (10.31%) and Nb 2 o 5 (0.39%) mixed uniformly and pre-fired at 850° C. for 5 hours to obtain piezoelectric ceramic powder.

[0033]Weigh 100g of lead zirconate titanate lanthanum piezoelectric ceramic powder, and take by weighing a surface treatment agent (stearic acid) whose mass is 1% of the powder mass, pour it into a ball mill jar and add zirconia grinding balls and grinding medium dehydrated alcohol Perform ball milling; the rotating speed is 400rmp, and the time is 24 hours. This process can grind the ceramic particles to reduce the particle size of the powder, and at the same time make the surfactant evenly attached to the surface of the ceramic powder. The mass ratio of ceramic powder and zirconia ball is 1:2, and the volume ratio of ceramic ...

Embodiment 2

[0042] The preparation formula is Pb 0.91 La 0.06 (Zr 0.58 Ti 0.42 ) 0.975 Nb 0.02 o 3 Lead lanthanum zirconate titanate piezoelectric ceramic powder, which is prepared by the method described in Example (1).

[0043] Take by weighing 100g lead lanthanum zirconate titanate piezoelectric ceramic powder, and take by weighing the surface treatment agent (lead stearate) that quality is described powder mass 2%, pour into ball mill pot and add grinding ball zirconia ball and grinding medium without Water and ethanol are ball milled; the rotating speed is 400rmp, and the time is 24 hours. This process can grind the ceramic particles to reduce the particle size of the powder, and at the same time make the surfactant evenly adhere to the surface of the ceramic powder, and modify the lead lanthanum zirconate titanate piezoelectric ceramics. The mass ratio of ceramic powder and zirconia ball is 1:2, and the volume ratio of ceramic powder and absolute ethanol is 1:1. After ball m...

Embodiment 3

[0052] The preparation formula is Pb 0.91 La 0.06 (Zr 0.58 Ti 0.42 ) 0.975 Nb 0.02 o 3 Lead lanthanum zirconate titanate piezoelectric ceramic powder, which is prepared by the method described in Example (1).

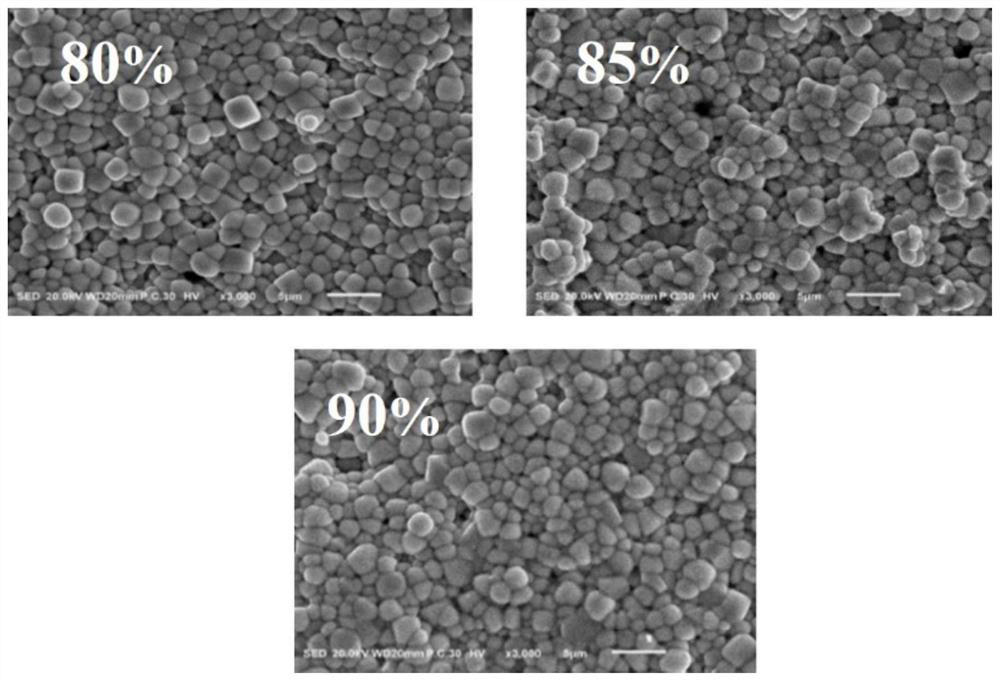

[0053] Weigh the lead zirconate titanate lanthanum piezoelectric ceramic powder, and weigh the surface treatment agent (lead stearate) whose mass is 2% of the powder mass, pour it into the ball mill jar and add grinding balls, zirconia balls and grinding media anhydrous Ethanol was ball milled; the rotating speed was 400rmp, and the time was 24 hours. This process can grind the ceramic particles to reduce the particle size of the powder, and at the same time make the surfactant evenly adhere to the surface of the ceramic powder, and modify the lead lanthanum zirconate titanate piezoelectric ceramics. The mass ratio of ceramic powder and zirconia ball is 1:2, and the volume ratio of ceramic powder and absolute ethanol is 1:1. After ball milling, it is dried and g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com