Highlight traceless spraying-free ABS material

An ABS material, high-gloss and non-marking technology, applied in the field of plastics, can solve the problems of affecting the effect of pearlescent, large damage to metal powder, etc., achieve good brightening effect, low cost, and improve toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

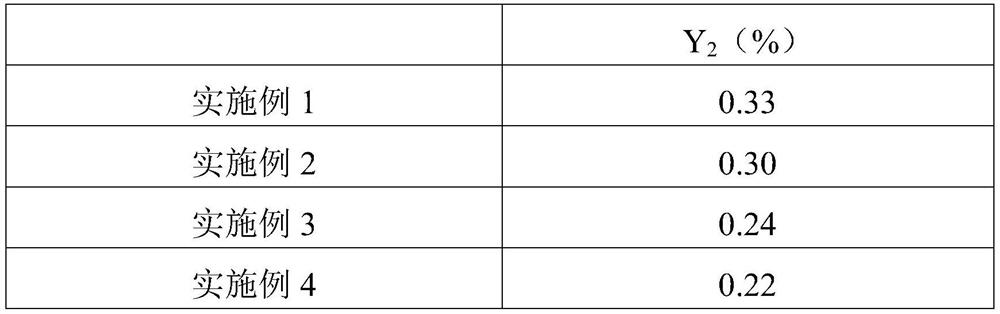

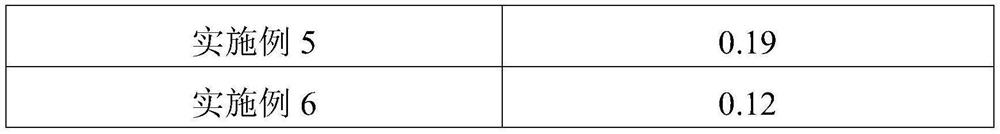

Examples

Embodiment 1

[0047] A high-gloss, traceless, spray-free ABS material is composed of the following raw materials in parts by weight: 80 parts by weight of ABS resin, 10 parts by weight of PMMA resin, and 1 part by weight of β-(3,5-di-tert-butyl-4-hydroxyphenyl) Octadecyl propionate, 2 parts by weight of potassium hexatitanate, 0.5 parts by weight of ethylene-acrylic acid copolymer, 3 parts by weight of ethylene-methyl acrylate-glycidyl methacrylate terpolymer, and 1 part by weight of melamine resin.

[0048] The preparation method of the high-gloss non-trace-free spray-free ABS material comprises the following steps: ABS resin, PMMA resin, β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, hexatitanium Potassium acrylate, ethylene-acrylic acid copolymer, ethylene-methyl acrylate-glycidyl methacrylate terpolymer, and melamine resin were added to a high-speed mixer and mixed evenly, then mixed by a twin-screw extruder, cooled and cut Granules to produce high-gloss non-marking spray-f...

Embodiment 2

[0050] A high-gloss non-marking spray-free ABS material, consisting of the following raw materials in parts by weight: 80 parts by weight of ABS resin, 10 parts by weight of PMMA resin, 5 parts by weight of glass beads, 1 part by weight of β-(3,5-di-tert-butyl -4-hydroxyphenyl) octadecyl propionate, 2 parts by weight of potassium hexatitanate, 0.5 parts by weight of ethylene-acrylic acid copolymer, 3 parts by weight of ethylene-methyl acrylate-glycidyl methacrylate terpolymer, 1 part by weight of melamine resin.

[0051] The preparation method of the high-gloss non-trace-free spray-free ABS material comprises the following steps: ABS resin, PMMA resin, glass microspheres, β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecanoic acid Ester, potassium hexatitanate, ethylene-acrylic acid copolymer, ethylene-methyl acrylate-glycidyl methacrylate terpolymer, and melamine resin are added to a high-speed mixer and mixed evenly, and then mixed by a twin-screw extruder , after cooling, pell...

Embodiment 3

[0053] A high-gloss non-marking spray-free ABS material is composed of the following raw materials in parts by weight: 80 parts by weight of ABS resin, 10 parts by weight of PMMA resin, 5 parts by weight of functionalized glass beads, 1 part by weight of β-(3,5-ditert Butyl-4-hydroxyphenyl) octadecyl propionate, 2 parts by weight of potassium hexatitanate, 0.5 parts by weight of ethylene-acrylic acid copolymer, 3 parts by weight of ethylene-methyl acrylate-glycidyl methacrylate terpolymer Material, 1 part by weight of melamine resin.

[0054] The preparation method of the functionalized glass microspheres comprises the following steps: S1 adding 10 parts by weight of glass microspheres and 15 parts by weight of vinyltriethoxysilane into 80 parts by weight of absolute ethanol for ultrasonic treatment for 20 minutes, wherein the ultrasonic power 800W, the ultrasonic frequency is 20kHz, centrifuged and dried to obtain pretreated glass beads;

[0055] S2 Add 4 parts by weight of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com