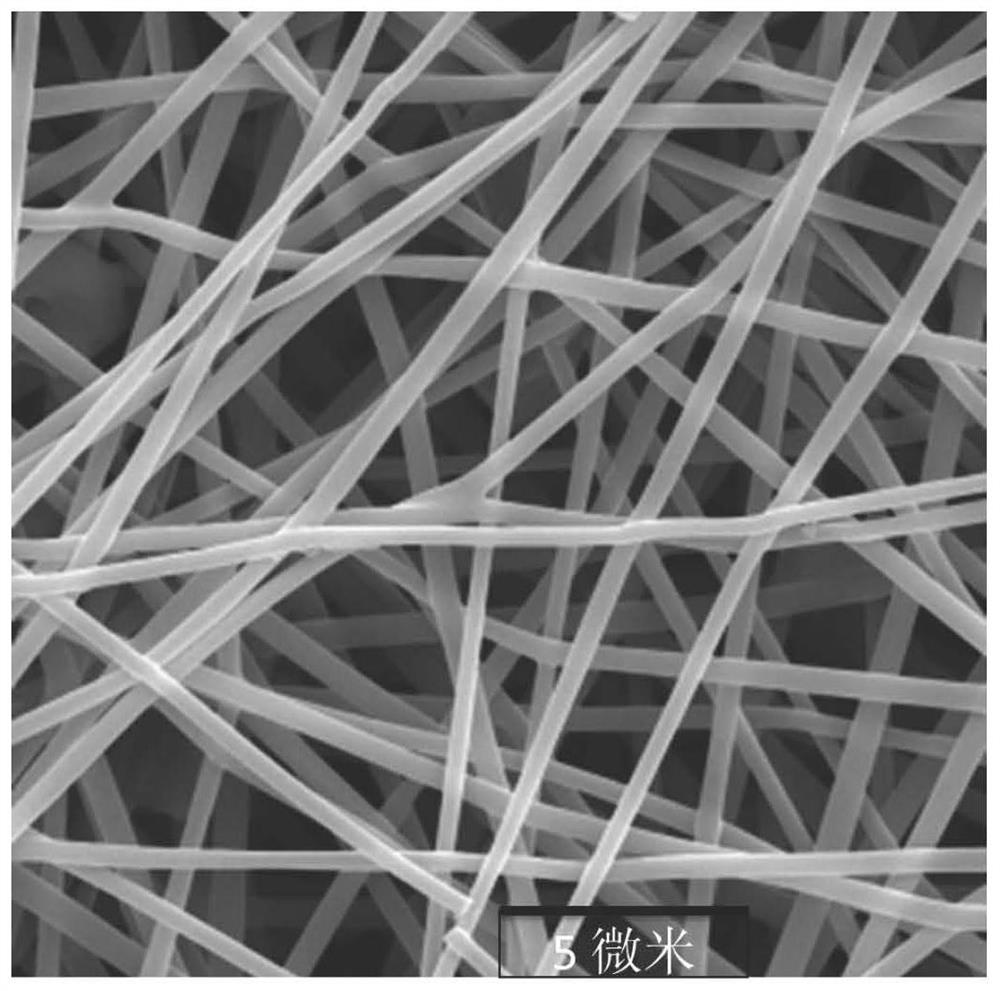

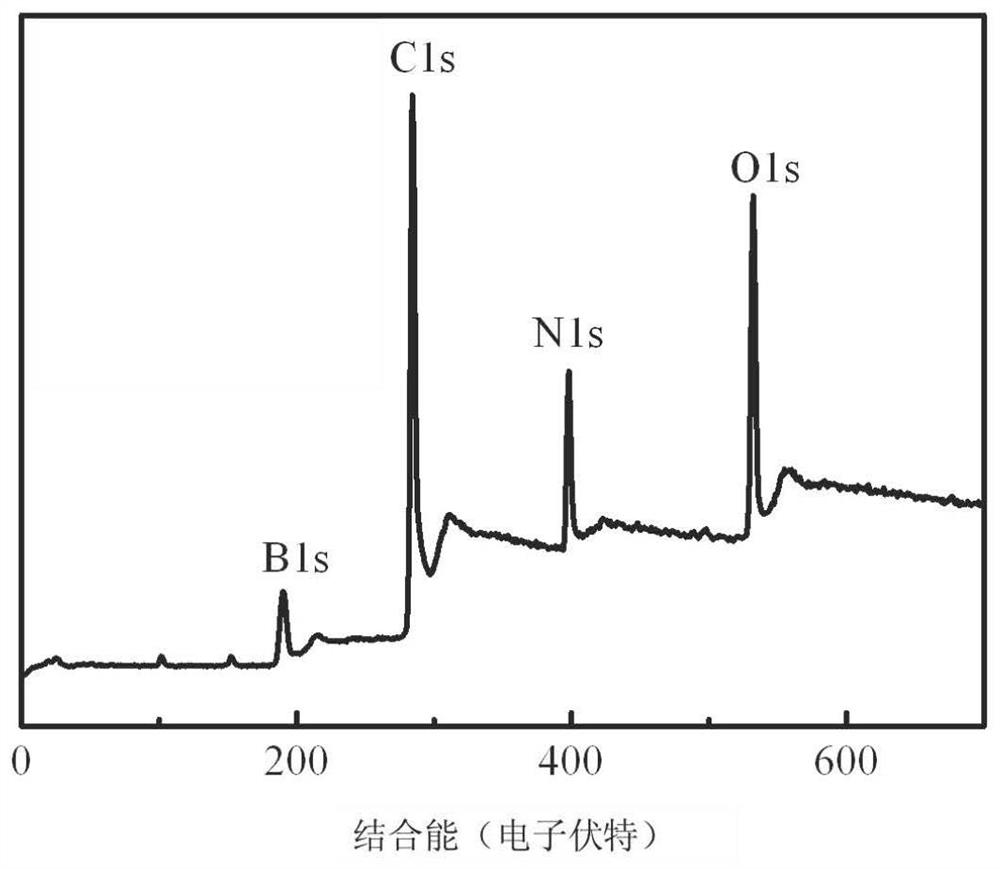

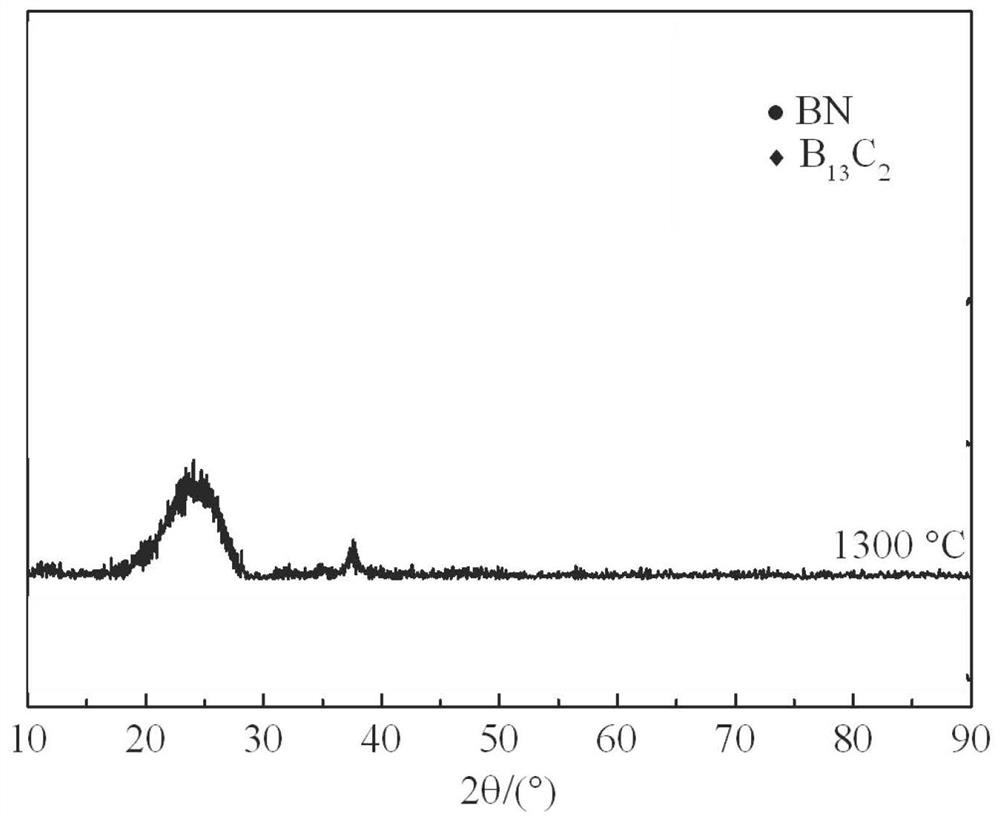

Preparation method of superfine-diameter BCN and BN ceramic fibers

A ceramic fiber and fine-diameter technology, which is applied in the field of preparation of BCN and BN ceramic fibers, can solve the problems of difficult content, low boron content, single composition of BCN nanofibers, etc., and achieve the effect of simple and easy synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the BCN ceramic fiber of superfine diameter, comprises the following steps:

[0035] (1) Synthesis of BCN ceramic precursor: equimolar B 10 h 14 React with diaminodiphenylmethane in tetrahydrofuran at room temperature for 12 hours, and then remove the solvent by distillation at 100°C for 6 hours to obtain a BCN ceramic precursor.

[0036] (2) Solution spinning to prepare superfine fiber felt: get the BCN ceramic precursor body synthesized in the previous step of 1g, weigh 1g polystyrene according to the ratio of 100% of the BCN ceramic precursor body quality, and both dissolve in N, N- 5mL of dimethylformamide was prepared into a spinning solution, and the spinning solution was added to a plastic syringe, and the outlet of the syringe was connected to a spinneret, and the spinning was carried out under a high-purity nitrogen pressure of 3MPa, and a stainless steel wire mesh was used as a receiving device. The propulsion speed of the spinning ...

Embodiment 2

[0040] The preparation method of the BN ceramic fiber of superfine diameter, comprises the following steps:

[0041] (1) Synthesis of BCN ceramic precursor: equimolar B 10 h 14 React with diaminodiphenylmethane in tetrahydrofuran at room temperature for 12 hours, and then remove the solvent by distillation at 100°C for 6 hours to obtain a BCN ceramic precursor.

[0042] (2) Solution spinning to prepare superfine fiber felt: get 1g of the BCN ceramic precursor synthesized in the previous step, weigh 0.5g polystyrene according to the 50% ratio of the BCN ceramic precursor quality, and dissolve the two together in N,N- A mixed solution of dimethylformamide and tetrahydrofuran (volume ratio 3:1) is configured as a spinning solution, and the spinning solution is added to a plastic syringe, and the outlet of the syringe is connected to the spinneret, and is carried out under a high-purity nitrogen pressure of 3MPa. For spinning, a stainless steel wire mesh is used as the receiving d...

Embodiment 3

[0046] The preparation method of the BCN ceramic fiber of superfine diameter, comprises the following steps:

[0047] (1) Synthesis of BCN ceramic precursors: equimolar B 10 h 14 React with 4,4'-diamino-2,2'-dimethylbiphenyl in tetrahydrofuran at room temperature for 12 h, and then remove the solvent by distillation at 100 °C for 6 h to obtain the BCN ceramic precursor.

[0048] (2) solution spinning prepares ultra-fine fiber felt: get the BCN ceramic precursor body synthesized in the previous step of 1g, take by weighing 0.6g polystyrene according to the ratio of 60% of the BCN ceramic precursor body quality, the two are dissolved in N, N - 5 mL of mixed solution of dimethylformamide and tetrahydrofuran (volume ratio 5:1), prepared as spinning solution, adding the spinning solution into a plastic syringe, and connecting the spinneret to the outlet of the syringe, under the high-purity nitrogen pressure of 3MPa Carry out spinning under the ground, adopt stainless steel wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com