Ternary material, preparation method thereof and lithium ion battery

A lithium-ion battery and ternary material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of slow lithium ion diffusion rate, poor material rate performance and low-temperature discharge performance, and difficulty in satisfying power batteries, etc., to achieve Good high temperature cycle performance and low temperature discharge performance, high specific capacity, high rate performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

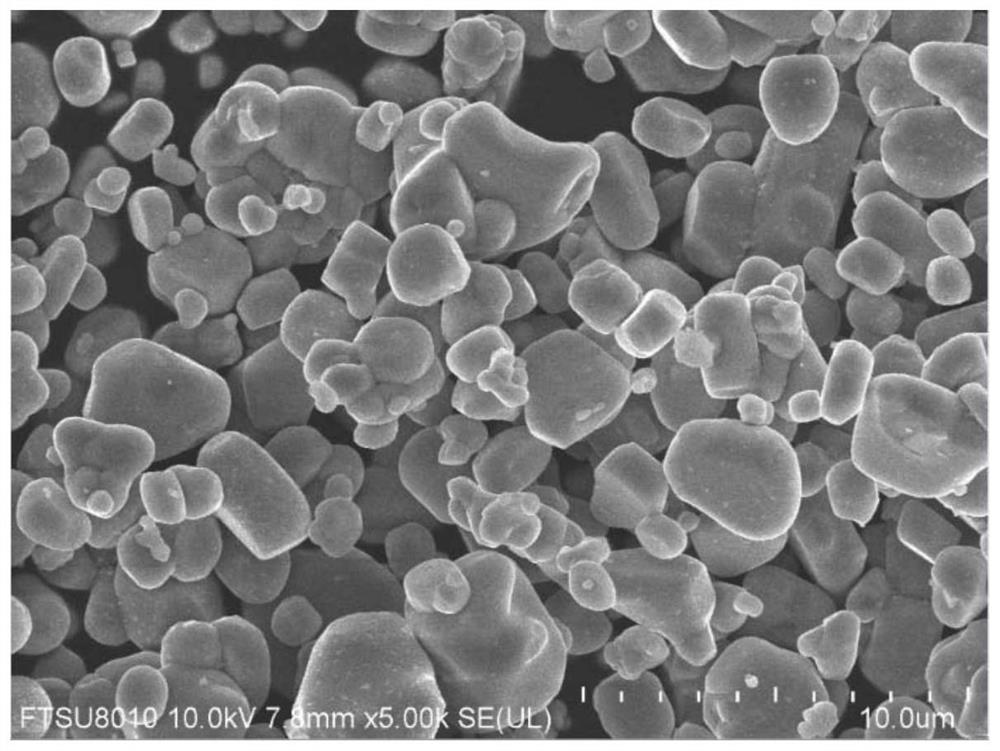

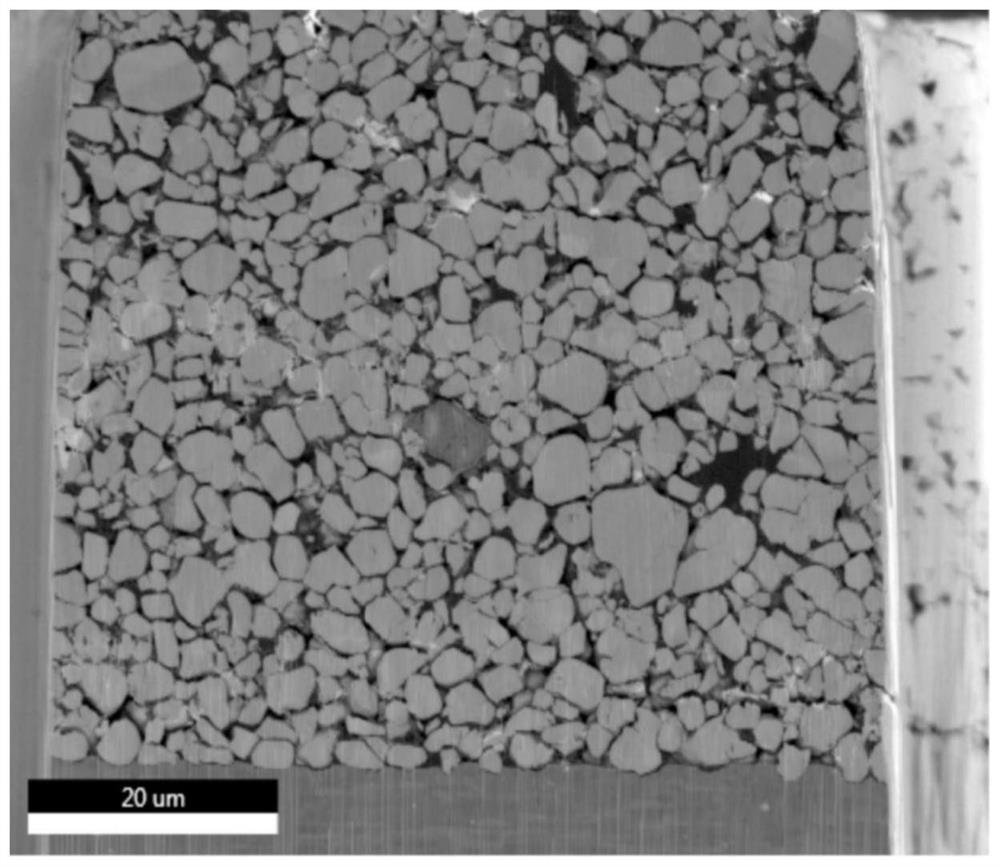

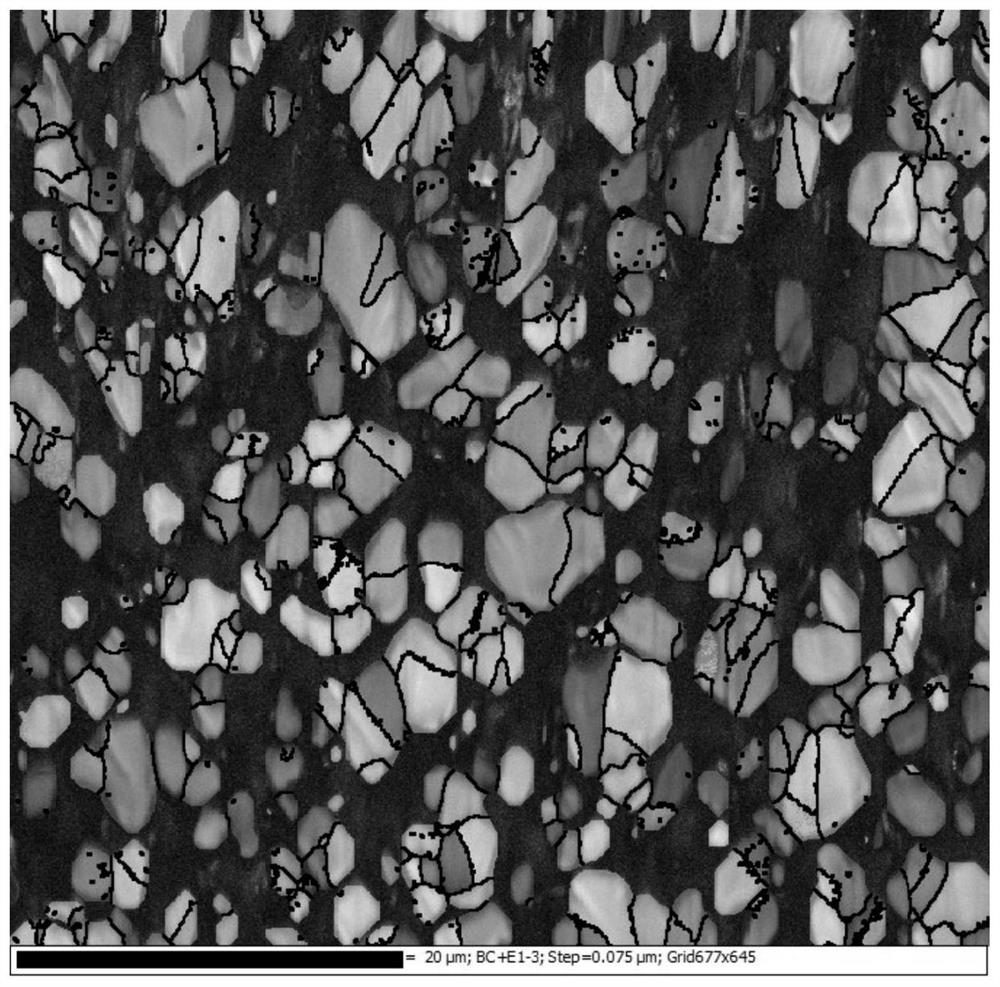

[0036] The preparation method of the present disclosure controls the BET specific surface area, sintering and crushing parameters of the precursor in the preparation process, so that the prepared ternary material has uniform particle size distribution and high mesoporosity, thereby having high specific capacity and high rate performance And good high temperature cycle performance and low temperature discharge performance.

[0037] In a specific embodiment according to the present disclosure, the method further includes: adding a doping solution to the co-precipitation solution to enhance the high-temperature cycle performance of the material, and the doping solution may contain Mg, Al, Ti, W, Y and One or more of Zr elements, preferably one or more of Mg, Ti and Zr elements, the disclosure does not limit the type of doping solution containing the above elements, preferably MgCl 2 solution, TiCl 4 solution and Zr(SO 4 ) 2 One or more of them in the solution. The pH of the c...

Embodiment 1

[0047] NiSO 4 ·6H 2 O, MnSO 4 4H 2 O. CoSO 4 ·6H 2 O is dissolved in deionized water and prepared as a reaction feed solution for subsequent use; sodium hydroxide is dissolved in deionized water to prepare a precipitant for subsequent use; ammonia water is prepared as a complexing agent for subsequent use; TiCl is prepared 4 and MgCl 2 The mixed solution is used as a doping solution for later use.

[0048] At the beginning of the co-precipitation reaction, ammonia water is first added to the deionized water as a complexing agent, and then the reaction feed liquid and a precipitating agent are added through a peristaltic pump. The precipitating agent is sodium hydroxide solution. NiSO 4 , MnSO 4 、CoSO 4 The flow rate of the solution is controlled according to the molar ratio of 6:2:2. After adjusting the valve and flow meter, it enters the reactor for stirring and mixing reaction. The amount of the precipitating agent and the complexing agent is controlled to maintain...

Embodiment 2

[0054] The ternary material was prepared by the method of Example 1, the only difference being: the temperature of the first constant temperature section in the first sintering was 780°C, and the time was 8.5h; the temperature of the second constant temperature section was 780°C, and the time was 10.5h ; The temperature of the third constant temperature section is 880°C, and the time is 10.5h; the temperature of the first heating section is 200-580°C, and the time is 3.5h; the temperature of the second heating section is 580-780°C, and the time is 3.5h; The temperature of the third heating section is 780-880°C, and the time is 3.5h; the temperature of the first cooling section is 880-700°C, and the time is 4.5h; the temperature of the second cooling section is 700-200°C, and the first The cooling time is 5h.

[0055] D of the resulting ternary material 99 11 μm, D 50 5.0 μm, D 1 The average pore diameter is 6nm, the porosity is 6%, and the volume ratio of pores with a pore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com