Method for preparing ZIF-8 composite film through electro-deposition and application of ZIF-8 composite film

A ZIF-8, electrodeposition technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of difficult control of defects and uneven thickness, and achieve less defects, uniform thickness, and mild synthesis conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

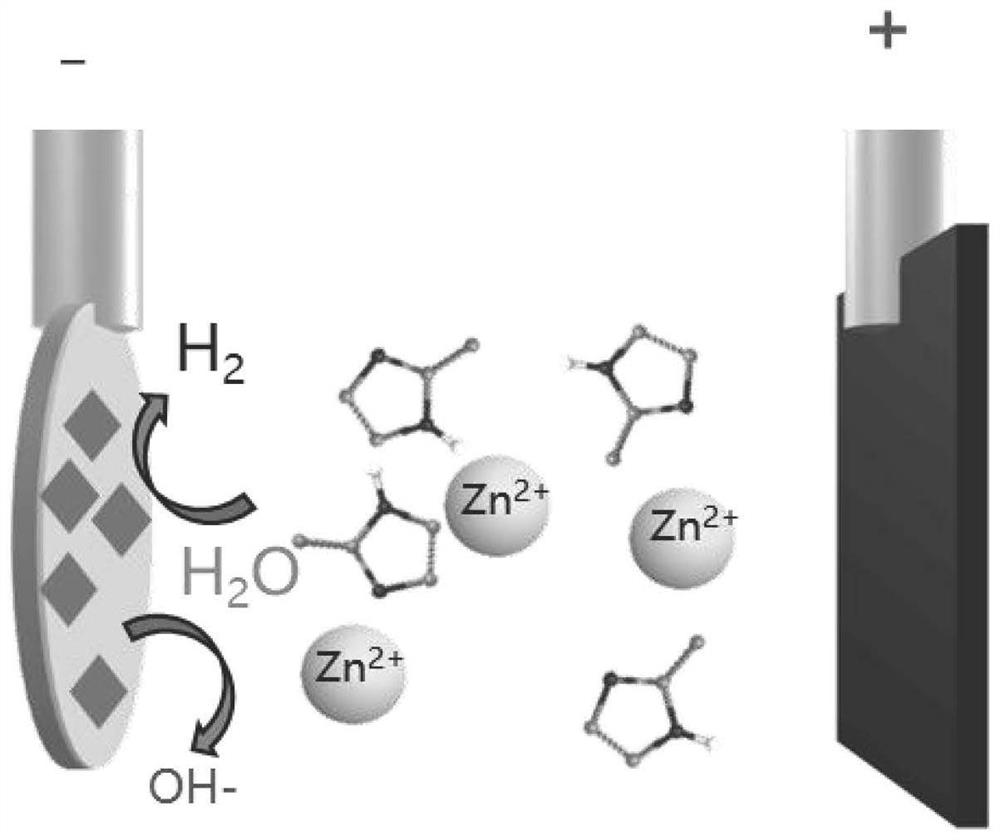

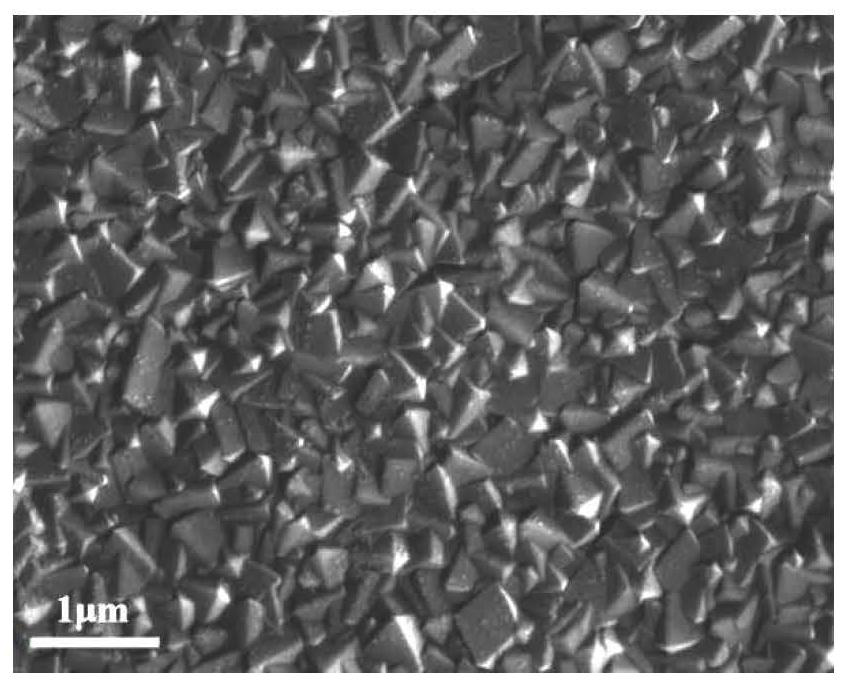

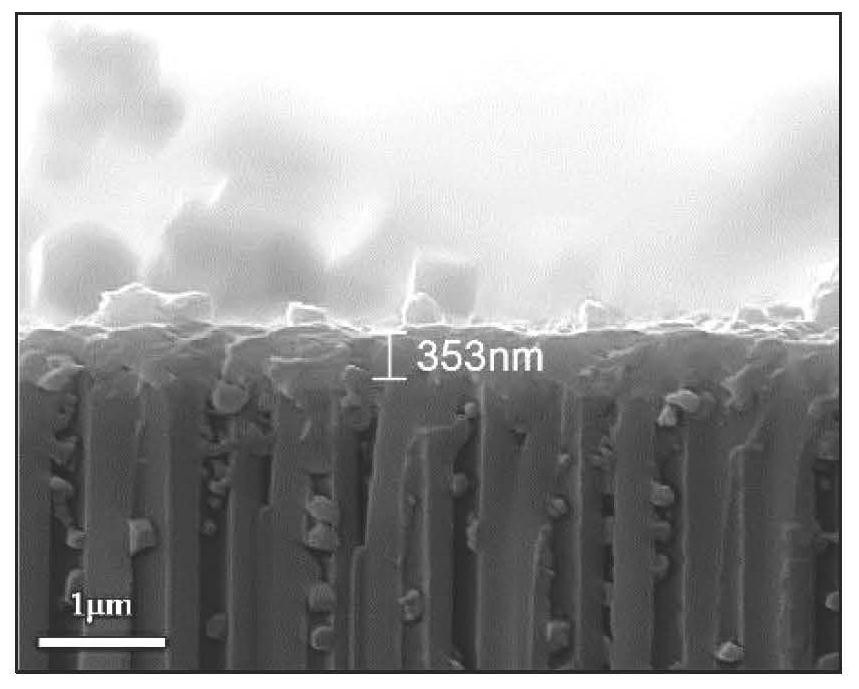

[0031] Specific Embodiment 1: In this embodiment, a method for preparing a ZIF-8 composite film by electrodeposition uses analytically pure zinc acetate dihydrate and 2-methylimidazole dissolved in deionized water as raw materials, and conducts electrodeposition at normal temperature and pressure. Synthesize, specifically, carry out according to the following steps:

[0032] 1. Preparation of electrodeposition precursor solution: 2-methylimidazole and zinc nitrate dihydrate were completely dissolved in deionized water respectively to obtain 2-methylimidazole solution and zinc nitrate dihydrate solution, and the two solutions were mixed and stirred to obtain ZIF -8 precursor solution;

[0033] 2. Pretreatment of the base film: rinse the base film in deionized water and dry it, sputter and deposit precious metals on the base film to obtain a conductive base film;

[0034] 3. Electrodeposition: Using a two-electrode deposition system, fix the conductive base film and graphite pa...

specific Embodiment approach 2

[0037] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the molar ratio of 2-methylimidazole to zinc nitrate dihydrate in step 1 is (60-70):1. Others are the same as the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment differs from Embodiment 1 to Embodiment 2 in that the 2-methylimidazole described in step 2 is dissolved in deionized water at a concentration of 0.8-1.2 mol / L. Others are the same as one of the specific embodiments 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com