Preparation method of bifunctional polymer adsorbent and application of bifunctional polymer adsorbent in gold recovery

A polymer and adsorbent technology, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., to achieve the effect of improving adsorption capacity, simple preparation method, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

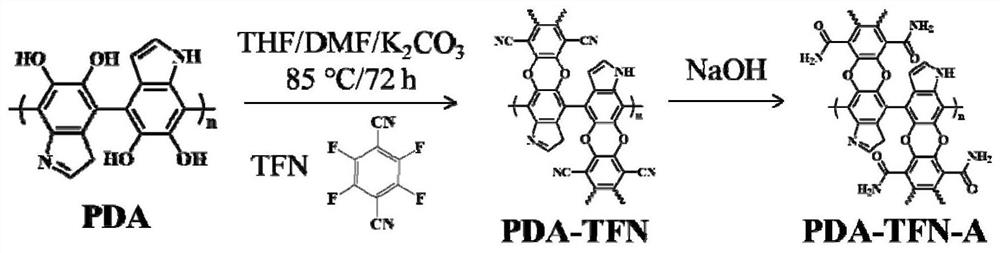

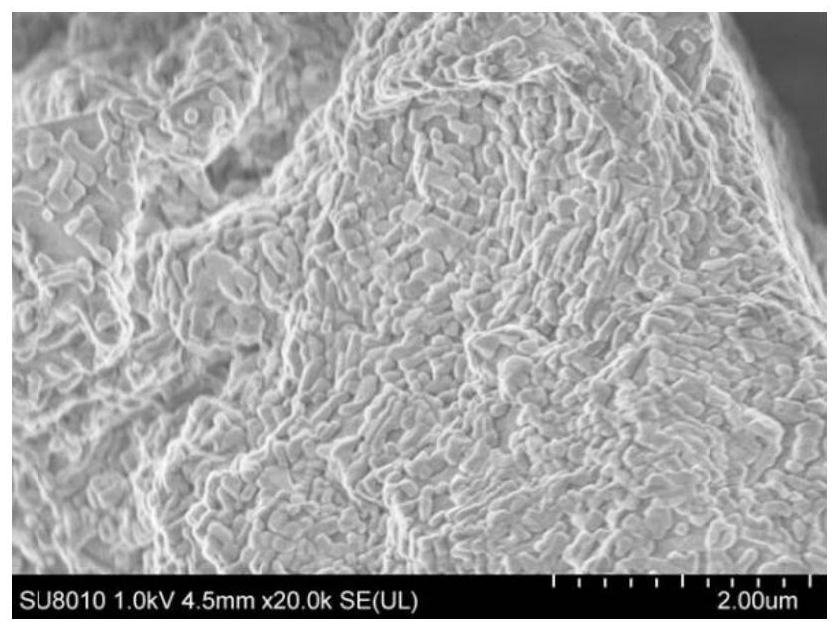

[0030] Example 1: Preparation method and characterization of a bifunctional polymer adsorbent

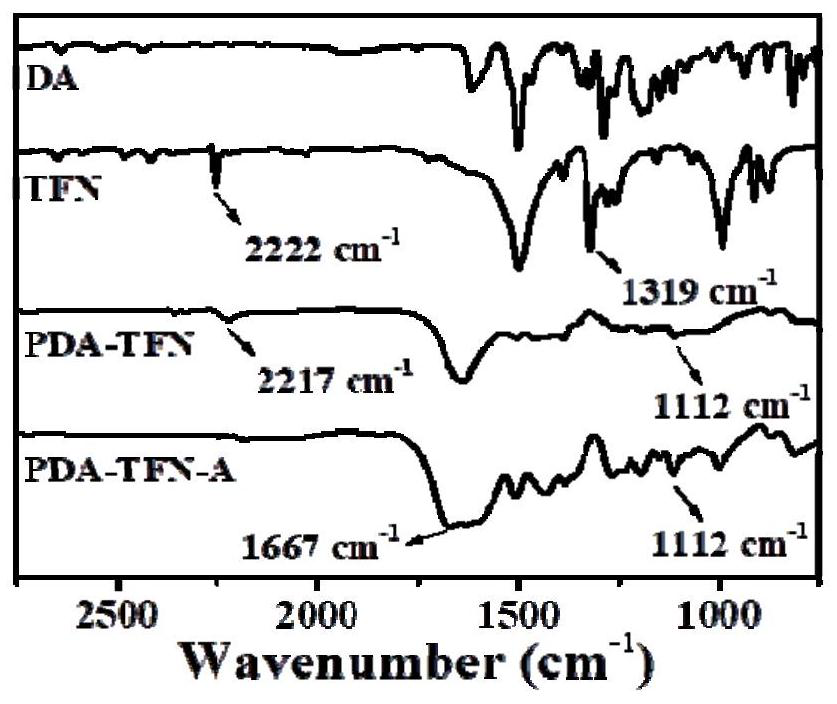

[0031] 1.8964g of dopamine, 1.0005g of tetrafluoroterephthalonitrile (TFN) and 2.764g of anhydrous potassium carbonate were placed in a three-neck round bottom flask, and then 80mL of anhydrous tetrahydrofuran / N,N-dimethylformamide (9 :1v / v), mix evenly and seal, vacuumize with vacuum pump for 20min, then feed nitrogen and stir at 85°C for 3 days under nitrogen atmosphere, take it out and cool to room temperature, remove nitrogen source, continue stirring at room temperature for 24h, The mixture was taken out and the precipitate was collected by filtration, and 0.5mol / L HCl solution was added dropwise until no CO 2 Effort to remove unreacted K 2 CO 3 , washed the precipitate with water, tetrahydrofuran, N,N-dimethylformamide, and acetone, and finally Soxhlet extracted in THF and acetone for 24 hours, and dried in vacuum at 60°C for 12 hours to obtain brown-black polymer PDA-TFN; ...

Embodiment 2

[0033] Example 2: Application of a dual-functional polymer adsorbent in the adsorption of gold

[0034] The pH value of the Au(III) solution was optimized. The results showed that when the pH of Au(III) solution was 2.0, the adsorption efficiency of Au(III) by the bifunctional polymer adsorbent PDA-TFN-A was the greatest. When the pH of the solution is higher than 5.0, the efficiency of PDA-TFN-A to adsorb Au(III) is low, which is due to the OH in aqueous chloride solution. - with Cl - Competing to form hydroxyl-containing gold complexes. Therefore, the optimal reaction pH value of Au(III) aqueous solution was selected as 2.0.

[0035] The adsorption capacity and adsorption kinetics of Au(III) on bifunctional polymer adsorbent PDA-TFN-A were studied. Potassium chloroaurate was dissolved in ultrapure water to prepare Au(III) solutions with different concentrations, and the pH value of the solution was adjusted to 2.0 with HCl or NaOH, and 5 mg of PDA-TFN-A was added to 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com