Defoaming method of sodium tungstate solution

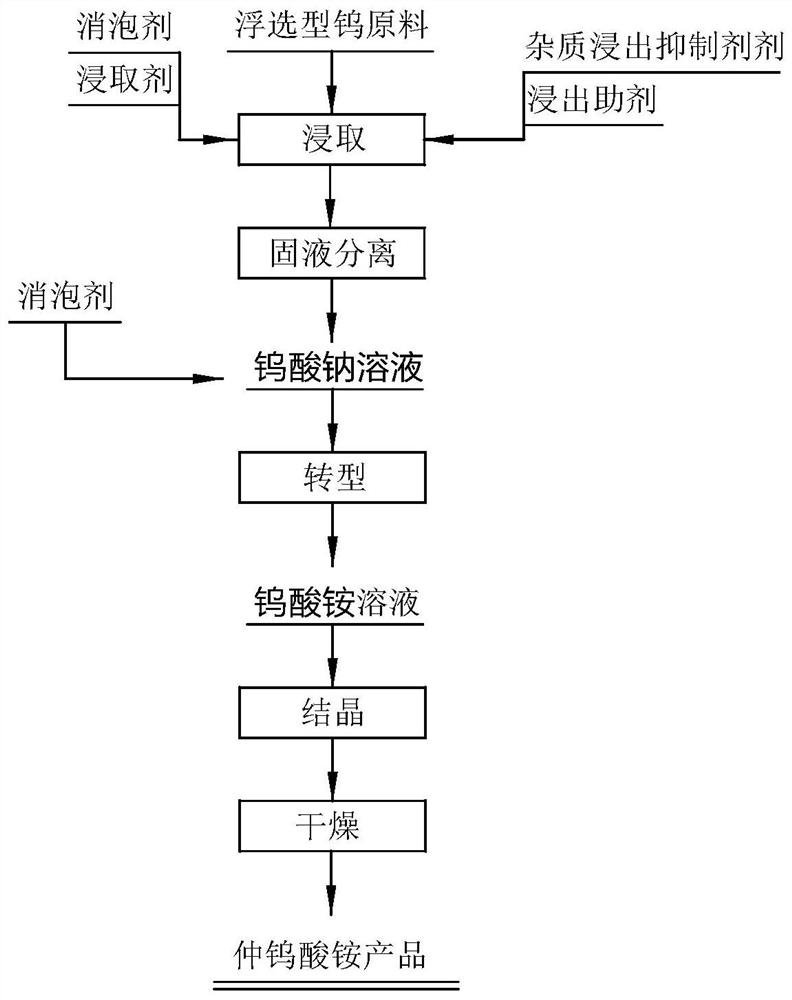

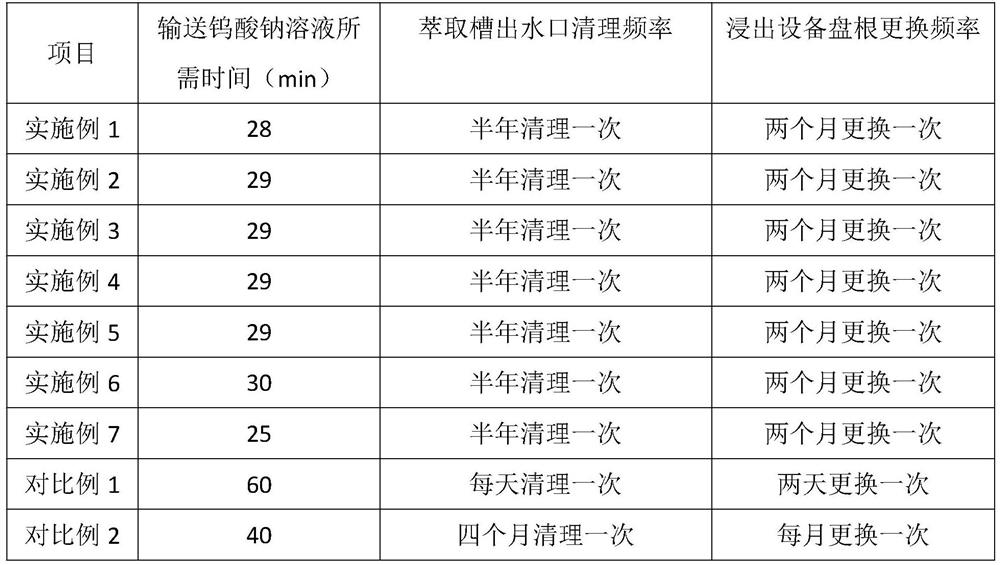

A sodium tungstate solution technology, which is applied in the defoaming of sodium tungstate solution and tungsten smelting process, can solve the problems of affecting ingredients, leaching, unclear grade of tungsten mineral raw materials entering smelting, and large differences in tungsten content. Achieve the effects of shortening the time of material liquid transportation, improving the effect of solution purification and improving the effect of leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A kind of defoaming method of sodium tungstate solution, comprises the following steps:

[0054] S1. Leaching of tungsten mineral raw materials: Add the flotation-type tungsten raw material and leaching agent into the leaching reactor at a mass ratio of 1:2, and add a defoamer. The mass ratio of the defoamer to the flotation-type tungsten raw material is 1 :1×10 9 , mixed evenly, and leached at 100°C for 8 hours to obtain a mixed slurry of sodium tungstate solution and leaching residue; wherein, the leaching agent was sodium carbonate.

[0055] S2. Solid-liquid separation: filter the mixed slurry obtained from the leaching reaction to obtain sodium tungstate solution and leaching residue, and the leaching residue is discharged out of the production system after being washed.

[0056] S3. Add defoamer to the sodium tungstate solution obtained by solid-liquid separation, add 100 mg of defoamer per liter of sodium tungstate solution, and disperse the defoamer in the sodiu...

Embodiment 2

[0064] A kind of defoaming method of sodium tungstate solution, comprises the following steps:

[0065] S1. Leaching of tungsten mineral raw materials: add the flotation-type tungsten raw material and leaching agent into the leaching reactor at a mass ratio of 1:3, and add a defoamer. The mass ratio of the defoamer to the flotation-type tungsten raw material is 1 :1×10 8 , mixed evenly, and leached for 7 hours at 120°C to obtain a mixed slurry of sodium tungstate solution and leaching residue; wherein, the leaching agent was sodium hydroxide.

[0066] S2. Solid-liquid separation: filter the mixed slurry obtained from the leaching reaction to obtain sodium tungstate solution and leaching residue, and the leaching residue is discharged out of the production system after being washed.

[0067] S3. Add defoamer to the sodium tungstate solution after solid-liquid separation, add 90 mg of defoamer per liter of sodium tungstate solution, and disperse the defoamer in the sodium tungs...

Embodiment 3

[0070] A kind of defoaming method of sodium tungstate solution, comprises the following steps:

[0071] S1. Leaching of tungsten mineral raw materials: add the flotation-type tungsten raw material and leaching agent into the leaching reactor at a mass ratio of 1:3, and add a defoamer. The mass ratio of the defoamer to the flotation-type tungsten raw material is 1 :1×10 6 , mixed evenly, and leached at 150°C for 6 hours to obtain a mixed slurry of sodium tungstate solution and leaching residue; wherein, the leaching agent was sodium fluoride.

[0072] S2. Solid-liquid separation: filter the mixed slurry obtained from the leaching reaction to obtain sodium tungstate solution and leaching residue, and the leaching residue is discharged out of the production system after being washed.

[0073] S3, often add defoamer to the sodium tungstate solution after solid-liquid separation, add 80 mg of defoamer per liter of sodium tungstate solution, and disperse the defoamer in the sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com