Phosphorus-free green environment-friendly water treatment agent for hot water boiler

A hot water boiler and water treatment agent technology, applied in water/sludge/sewage treatment, descaling and water softening, chemical instruments and methods, etc., can solve national property losses, affect heating, and fail to prevent corrosion Scale and other problems, to avoid secondary pollution, slow down metal corrosion, avoid the effect of new scale formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A non-phosphorus, green and environment-friendly water treatment agent for hot water boilers, comprising the following components in percentage by weight: maleic anhydride 20%, ammonia water 16%, disodium edetate 11%, sodium polyaspartate 14% %, sodium hydroxide 10%, copper corrosion inhibitor 0.1%, additives 5%, imidazoline 0.6% and water 23.3%.

[0029] Auxiliaries include any one or a mixture of dispersants, bactericides, and pre-film protection agents.

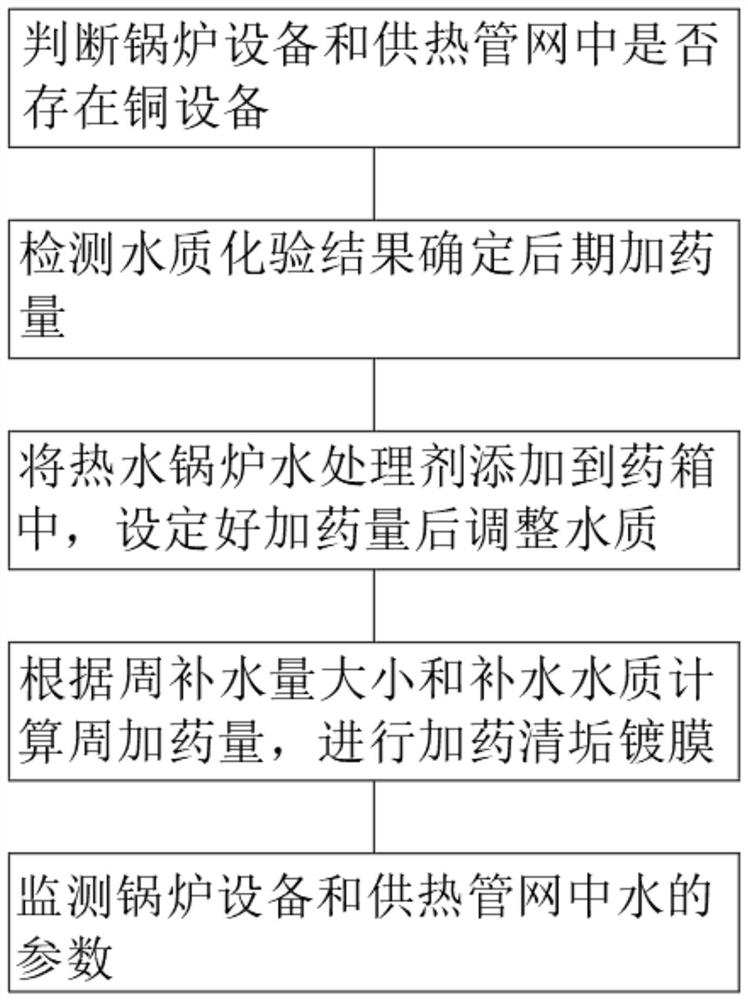

[0030] A method for using a phosphorus-free, green and environmentally friendly hot water boiler water treatment agent comprises the following steps:

[0031] ①. Determine whether there is copper equipment in the boiler equipment and heating pipe network.

[0032] ②. Test the results of water quality tests to determine the amount of dosing in the later stage;

[0033] The dosing amount is determined according to the water capacity and water quality of boiler equipment and heating pipe network.

[0034] ③. Add the...

Embodiment 2

[0041] A non-phosphorus, green and environment-friendly water treatment agent for hot water boilers, comprising the following components in percentage by weight: maleic anhydride 20%, ammonia water 20%, edetate disodium 10%, polyaspartic acid sodium 13% %, sodium hydroxide 10%, copper corrosion inhibitor 0.1%, additives 5%, imidazoline 0.5% and water 21.4%.

[0042] A method for using a phosphorus-free, green and environmentally friendly hot water boiler water treatment agent comprises the following steps:

[0043] ①. Determine whether there is copper equipment in the boiler equipment and heating pipe network.

[0044] ②. Test the results of water quality tests to determine the amount of dosing in the later stage;

[0045] The dosing amount is determined according to the water capacity and water quality of boiler equipment and heating pipe network.

[0046] ③. Add the hot water boiler water treatment agent to the medicine box, and adjust the water quality after setting the d...

Embodiment 3

[0053]A non-phosphorus, green and environment-friendly water treatment agent for hot water boilers, comprising the following components in percentage by weight: maleic anhydride 20%, ammonia water 17%, disodium edetate 10%, sodium polyaspartate 13% %, sodium hydroxide 11%, copper corrosion inhibitor 0.2%, additives 6%, imidazoline 0.6% and water 22.2%.

[0054] A method for using a phosphorus-free, green and environment-friendly hot water boiler water treatment agent, comprising the following steps:

[0055] ①. Determine whether there is copper equipment in the boiler equipment and heating pipe network.

[0056] ②. Test the results of water quality tests to determine the amount of dosing in the later stage;

[0057] The dosing amount is determined according to the water capacity and water quality of boiler equipment and heating pipe network.

[0058] ③. Add the hot water boiler water treatment agent to the medicine box, and adjust the water quality after setting the dosage; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com