Preparation method of cross-linked polyurethane microspheres coated with carbon black particles, polyurethane microspheres and application thereof

A cross-linked polyurethane and carbon-coated technology, which is used in the preparation of microspheres, polyurea/polyurethane coatings, microcapsule preparations, etc. cracking and other problems, to achieve the effect of easy dispersion, excellent matting and UV protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

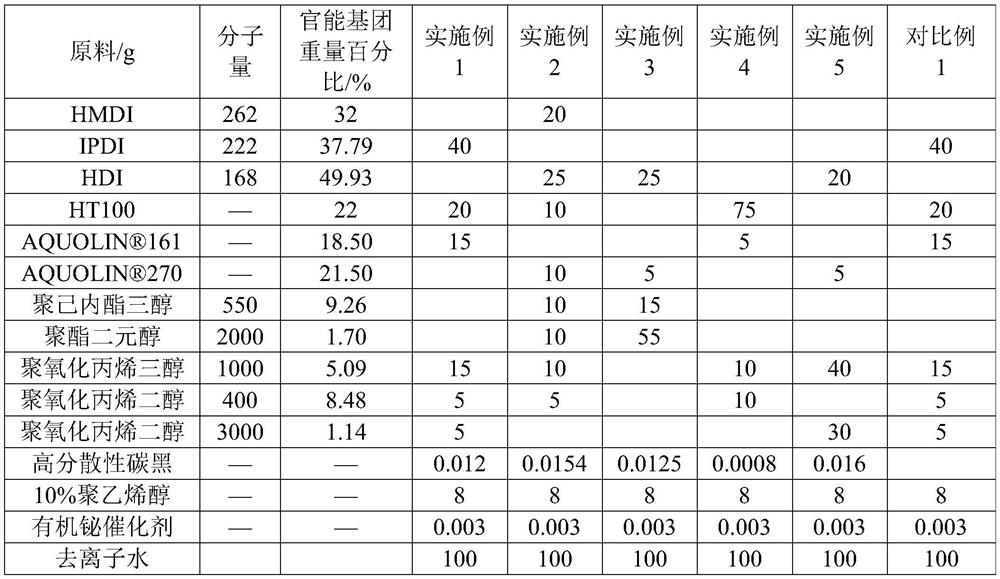

[0074] According to the components and their parts by weight shown in Table 1, at room temperature, take the polyisocyanate monomer first, and use a high-speed disperser at 1500 rpm to uniformly disperse the carbon black into the polyisocyanate monomer. Speed to 500rpm and stir for 15min. Then, polyester and / or polyether polyol, hydrophilized polyisocyanate and catalyst are sequentially added under stirring conditions, stirred for 5 minutes, and mixed uniformly to form an organic phase mixture. Stop stirring, add deionized water to the organic phase at one time, use a high-speed disperser at 2000 rpm, disperse for 10 minutes, then pour it into a 500 ml three-necked flask, add a 10% mass concentration of polyvinyl alcohol solution, at 150 rpm The temperature was raised to 50°C under stirring, and the temperature was raised to 90°C for 1 hour after reaction for 6 hours, cooled to room temperature, and filtered through a 100-mesh filter to obtain a suspension of polyurethane mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com