A kind of photochromic lens and its production process

A color-changing lens and production process technology, applied in the field of optical films, can solve problems such as photochromic dye damage, achieve good light transmittance, improve hardness and solvent resistance, and improve product qualification rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

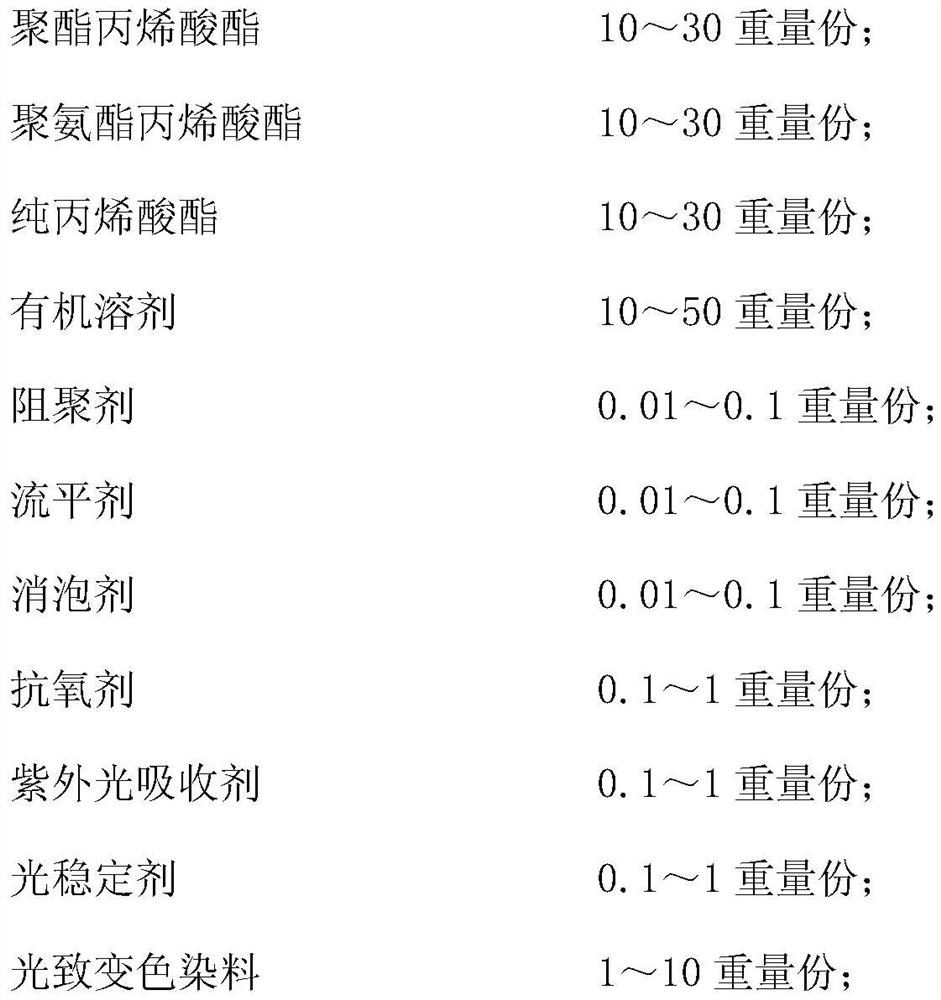

[0058] Prepare the first layer of photochromic composition:

[0059]In the reactor, drop into 3.5g midnight gray (photochromic powder), 3.5g misty gray (photochromic powder), 0.2g BASF Tinuvin292 (light stabilizer), 0.2g Tinuvin 329 (ultraviolet light absorber), 0.2g BHT (antioxidant), 0.1g BYK333 (leveling agent), 0.1g BYK1790 (defoamer) and 50g dimethyl carbonate (organic solvent), heat up to 80-95°C, keep stirring for 1-2 hours, Put in 15g GU3010Z (polyurethane acrylate), 20g GU2168Z (polyester acrylate), 10g GU2271B (pure acrylate), 0.05g MEHQ (polymerization inhibitor), and keep stirring at 55-70°C for 20-50 minutes to obtain photoinduced Color changing composition.

Embodiment 2

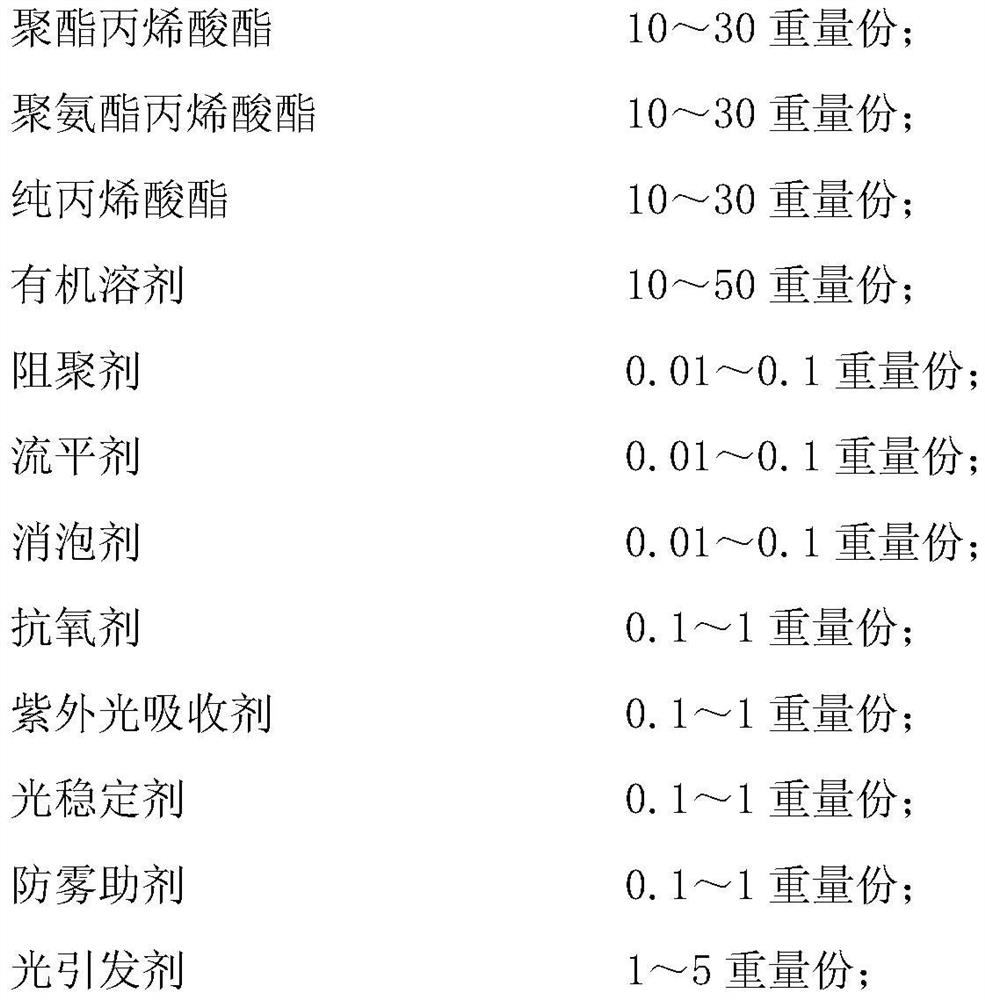

[0061] Prepare the second protective layer composition:

[0062] Drop into 1g sodium acrylate (anti-fog additive), 2g photoinitiator 184, 2g photoinitiator TPO, 0.2g BASF Tinuvin292, 0.2g Tinuvin 329 (ultraviolet absorber), 0.2g BHT (antioxidant) in the reactor ), 0.1g BYK333 (leveling agent), 0.1g BYK1790 (defoamer) and 50g ethanol (organic solvent), heat up to 50-70°C, keep stirring for 20-50 minutes, then put in 15g GU3010Z (polyurethane acrylate) , 20g GU9315Z (polyester acrylate), 10g GU2271B (pure acrylate), 0.05g MEHQ (polymerization inhibitor), after stirring at 55-70°C for 20-50 minutes, the protective layer composition was obtained.

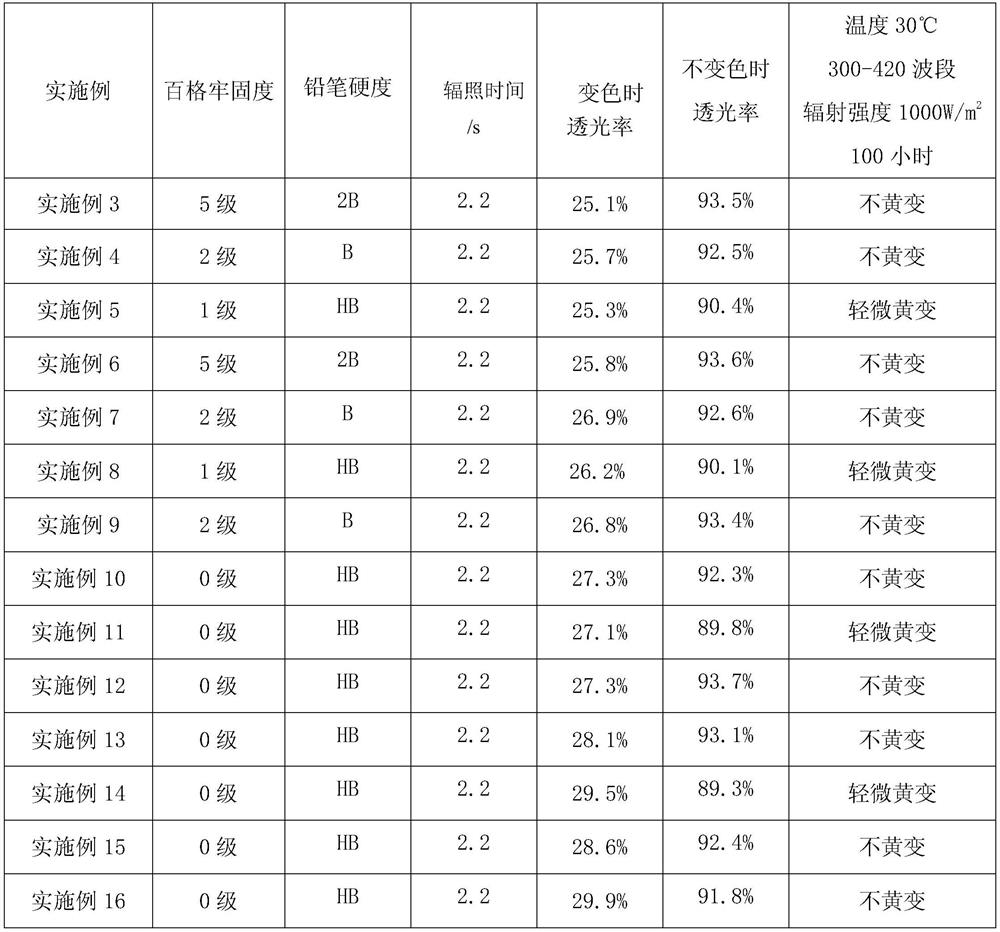

Embodiment 3

[0064] The lens substrate is sucked by the intelligent manipulator, and the lens is placed in a fixed position facing down. The photochromic liquid is sprayed onto the surface of the lens from bottom to top by spraying. After 5 seconds, the intelligent manipulator raises its height and starts to rotate at 1500rpm. After counting and rotating for 20 seconds, it stops, and then the intelligent manipulator puts the side of the lens coated with the color-changing liquid upward on the track, bakes it with a 200W infrared lamp for about 2 minutes, and then passes it through EB Electronics under the protection of nitrogen. Beam curing to form a film, the distance between the electron beam emission window and the lens is set to 5cm, the voltage of the EB electron beam is set to 70kv, the dose is set to 50KGy, and the oxygen content detection value is below 200PPM. The intelligent manipulator absorbs it, puts the side of the lens coated with the color-changing liquid down and places it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com