Natamycin-grafted oxidized alginic acid fiber membrane and preparation method thereof

A technology for oxidizing alginic acid and catacinamycin, which is applied in the field of medical materials and can solve the problem of low degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

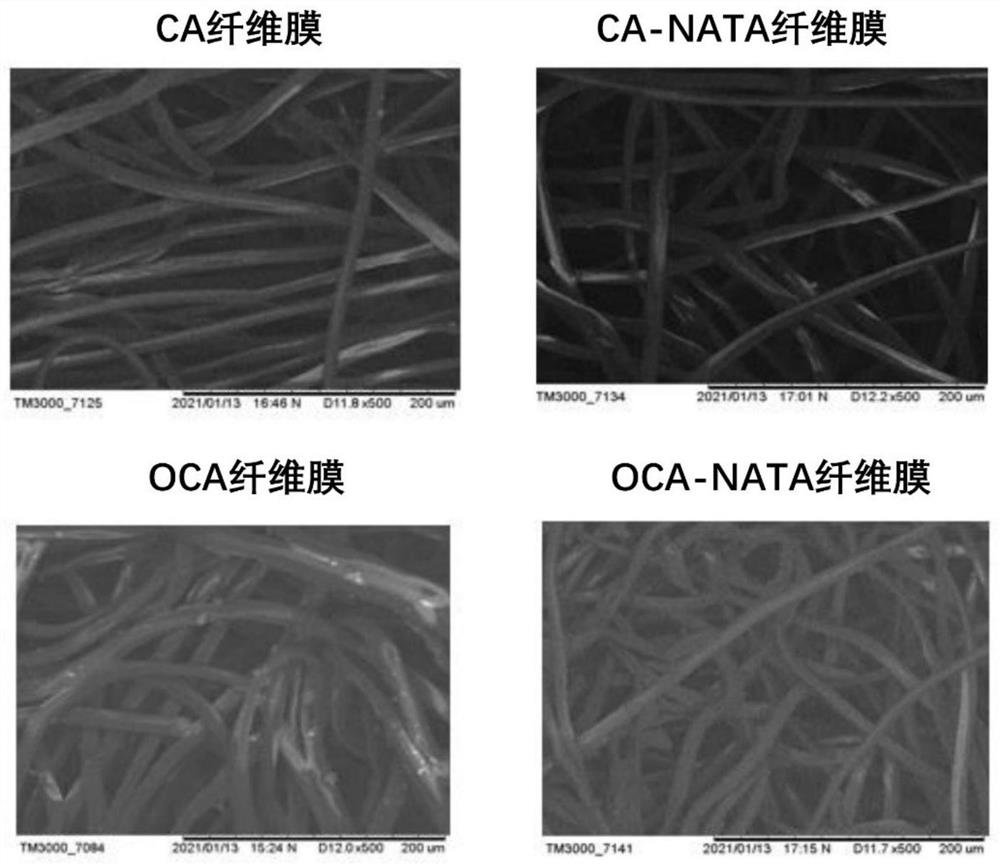

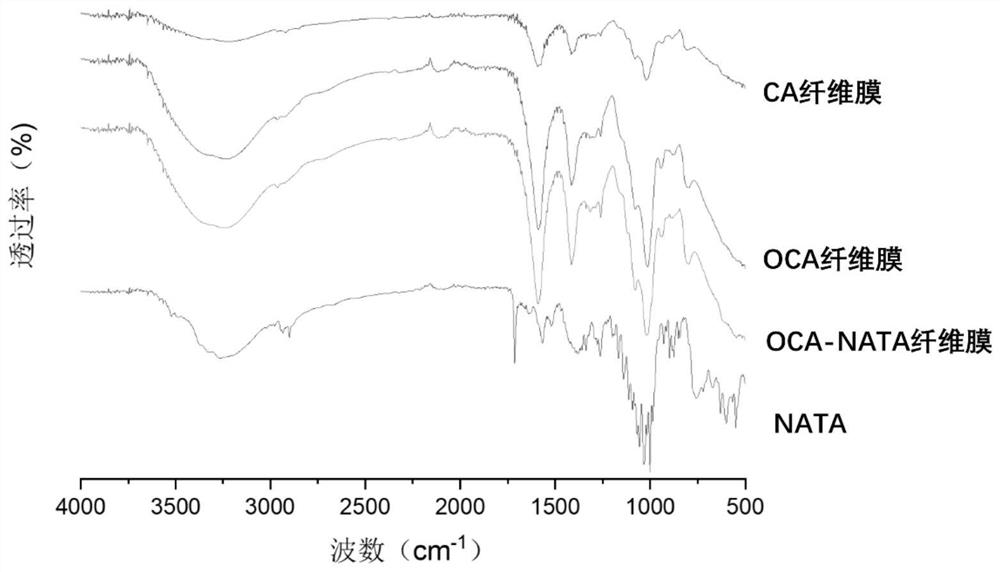

[0023] This example relates to an oxidized alginate fiber membrane grafted with natamycin, which is prepared by soaking the oxidized alginate fiber in an aqueous solution of natamycin, and reacting the oxidized alginate fiber with natamycin in a Schiff base, specifically The preparation process is as follows:

[0024] (1) Preparation of oxidized alginic acid fiber: take alginic acid fiber, rinse it with sterilized double distilled water, remove impurities on the surface of the fiber, then dry it at 45°C to constant weight, and then put it into Soak in sodium periodate aqueous solution, stir and react at 40°C for 0.5-1.5 hours at a constant temperature in the dark, to generate oxidized alginic acid (OCA) fibers;

[0025] (2) Soak the oxidized alginic acid fiber in a glycerol aqueous solution with a molar concentration of 0.1mol / L for half an hour to remove unreacted sodium periodate, then rinse it with sterilized double distilled water for 3 times, and put it in an oven Dry at...

Embodiment 2

[0029] This example relates to an oxidized alginate fiber membrane grafted with natamycin, which is prepared by soaking the oxidized alginate fiber in an aqueous solution of natamycin, and reacting the oxidized alginate fiber with natamycin in a Schiff base, specifically The preparation process is as follows:

[0030] (1) Preparation of oxidized alginic acid fiber: take alginic acid fiber, rinse with sterilized double distilled water to remove impurities on the surface of the fiber, then dry at 45°C to constant weight, and then add high iodine with a mass concentration of 1g / L Soak in sodium nitrite aqueous solution, stir and react at 40°C for 1 hour at a constant temperature in the dark, to generate oxidized alginic acid (OCA) fibers;

[0031] (2) Soak the oxidized alginic acid fiber in a glycerol aqueous solution with a molar concentration of 0.1mol / L for half an hour to remove unreacted sodium periodate, then rinse it with sterilized double distilled water for 3 times, and ...

Embodiment 3

[0035] This example relates to an oxidized alginate fiber film grafted with natamycin, which is prepared by soaking the oxidized alginate fiber in an aqueous solution of natamycin, and the oxidized alginate fiber undergoes a Schiff base reaction with natamycin, specifically The preparation process is as follows:

[0036](1) Preparation of oxidized alginic acid fiber: take the woven alginic acid fiber, rinse it with sterilized double distilled water to remove impurities on the surface of the fiber, then dry it at 45°C to constant weight, and then put it into the Soak in L of sodium periodate aqueous solution, stir and react at 40°C for 0.5 hours at a constant temperature in the dark to avoid light, and generate oxidized alginic acid (OCA) fibers;

[0037] (2) Soak the oxidized alginic acid fiber in a glycerol aqueous solution with a molar concentration of 0.1mol / L for half an hour to remove unreacted sodium periodate, then rinse it with sterilized double distilled water for 3 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com