Carbodiimide modified polyisocyanate, preparation method thereof and catalyst system

A polyisocyanate and carbodiimide technology, applied in the field of modified isocyanates, can solve problems such as reducing the crystallization point of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

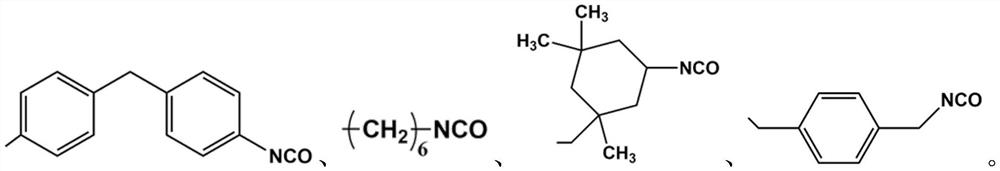

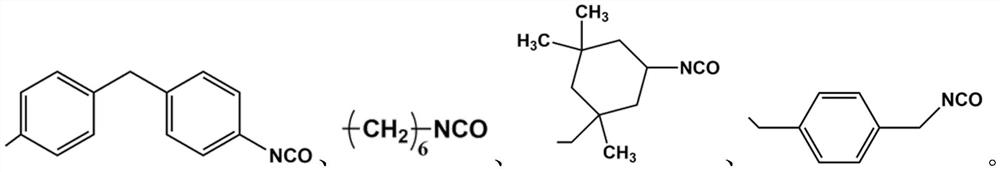

Method used

Image

Examples

Embodiment 1

[0056] Tetramethylgermanium and triethyl phosphate are mixed uniformly at 45°C in a mass ratio of 1:1000 as a composite catalyst for later use. 600g diphenylmethane diisocyanate in N 2 Stir in the atmosphere, add 1wt% compound catalyst, mix evenly and quickly heat to 150°C, add 120g of diphenylmethane diisocyanate quickly after 3 hours of reaction, and cool down to 80°C with circulating water at the same time, continue stirring for 30min to get the final product . At this time, the monomer content in the product is 75%, the composition of carbodiimide and uretonimine is 20%, the content of the structural component of formula I is 5%, and the product can be stored in a liquid state for 180 days at -15°C.

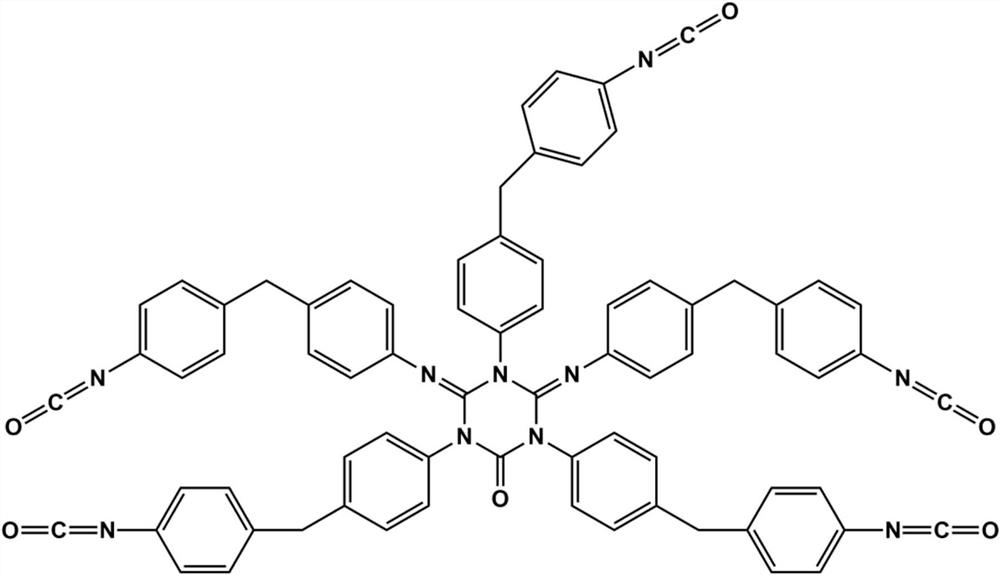

[0057] Formula I structural formula:

[0058]

[0059] The mass spectrum result of formula I is as follows:

[0060] Chemical Formula: C 73 h 50 N 10 o 6

[0061] Exact Mass: 1162.39

[0062] Molecular Weight: 1163.24

[0063] m / z: 1162.39 (100.0%), 1163.39 (82.6...

Embodiment 2

[0067] Mix dibutyltin dilaurate and triethyl phosphate at a mass ratio of 3:1000 at 45°C and use it as a composite catalyst for future use. 600g diphenylmethane diisocyanate in N 2 Stir in the atmosphere, add 3wt% of the compound catalyst, mix evenly and quickly heat to 180°C, react for 2.5h and quickly add 180g of diphenylmethane diisocyanate, and cool down to 80°C with circulating water at the same time, continue stirring for 30min to get the final product. At this time, the monomer content in the product is 72%, the composition of carbodiimide and uretonimine is 22%, the content of the structural component of formula I is 6%, and the product can be stored in a liquid state for 200 days at -15°C.

Embodiment 3

[0069] Mix tetraethylgermanium and triethyl phosphate at a mass ratio of 5:1000 at 45°C and use it as a composite catalyst for later use. 600g diphenylmethane diisocyanate in N 2 Stir in the atmosphere, add 5wt% compound catalyst, mix evenly and quickly heat to 195°C, add 200g of diphenylmethane diisocyanate quickly after 2 hours of reaction, and cool down to 80°C with circulating water at the same time, continue stirring for 30min to get the final product . At this time, the monomer content in the product is 69%, the composition of carbodiimide and uretonimine is 23%, the content of the structural component of formula I is 8%, and the product can be stored in a liquid state for 220 days at -15°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com