Liquefied aromatic amine curing agent composition and preparation method thereof, epoxy resin composition and application

A technology of aromatic amine curing agent and epoxy resin, which is applied in the field of liquefied aromatic amine curing agent composition and its preparation, and epoxy resin composition, and can solve the mechanical properties of POSS such as high synthesis cost, complicated process, and epoxy resin toughness No significant improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

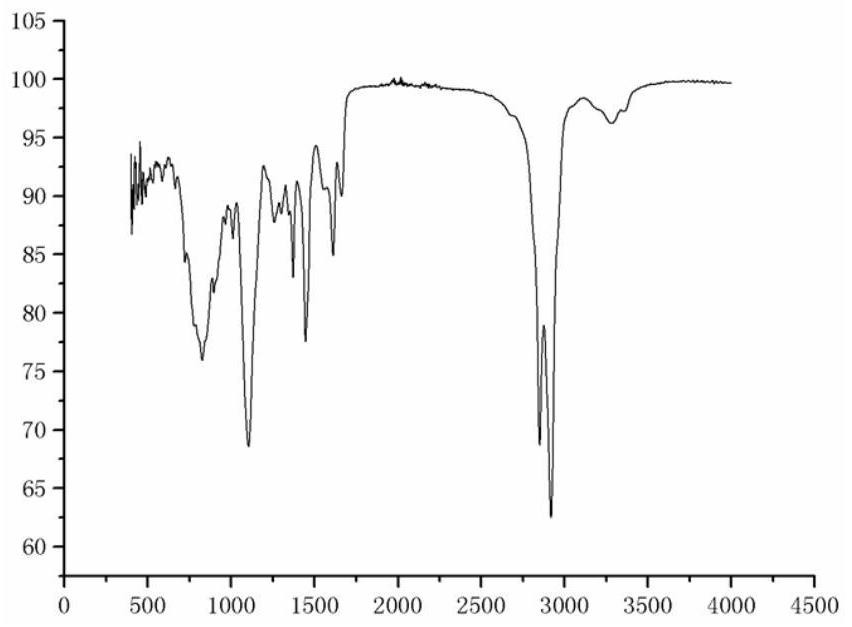

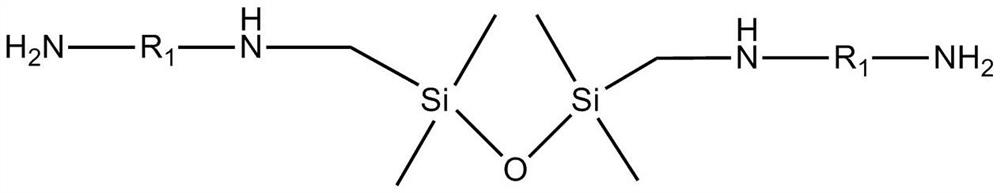

[0041] (1) Diaminodiphenylmethane and 1,3-bis(chloromethyl)-1,1,3,3-tetramethyldisiloxane were dissolved in xylene at a molar ratio of 2:1, The amount of xylene is: 7.5 mL of xylene solvent is needed for every 1 mmol of reactant, the reaction time is 0.5 hour, and the reaction temperature is 80°C; triethylamine catalyst is used, the amount is 3mol% of diaminodiphenylmethane, and the temperature is 150°C after the reaction Atmospheric pressure distillation removes impurities such as solvents to obtain product A, which is characterized by infrared, and the results are as follows figure 1 shown; figure 1 Medium 800cm -1 and 1080cm -1 The absorption peak indicates that the silicon-oxygen bond is introduced into the A structure molecule, 1630cm -1 The absorption peak indicates the existence of Si-N-H bond, thus proving that 1,3-bis(chloromethyl)-1,1,3,3-tetramethyldisiloxane modified aromatic amine A structure curing agent was successfully prepared;

[0042] (2) Dissolve diamin...

Embodiment 2

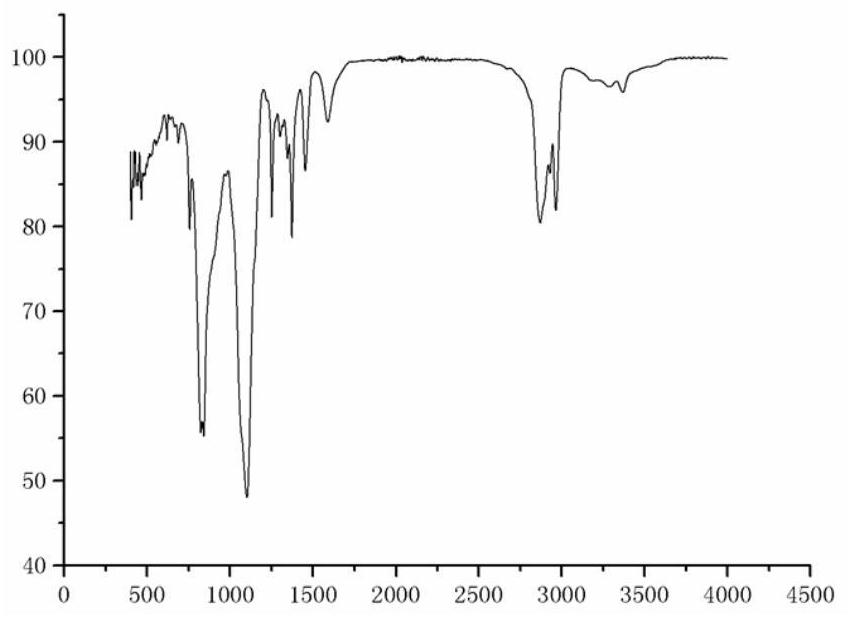

[0045] (1) Diaminodiphenylsulfone and 1,3-bis(chloromethyl)-1,1,3,3-tetramethyldisiloxane were dissolved in tetrahydrofuran at a molar ratio of 3:1, and the amount of tetrahydrofuran For: every 1mmol reactant needs 10mL of THF solvent, the reaction time is 1 hour, using sodium carbonate catalyst, the dosage is 5mol% of diaminodiphenyl sulfone, and the reaction temperature is 60°C; after the reaction is completed, the solvent is removed by 80°C normal pressure distillation and other impurities to obtain the A product; (2) dissolving diaminodiphenyl sulfone and trichloroethyl phosphate in tetrahydrofuran according to a molar ratio of 3:1, and the amount of tetrahydrofuran is: 10 mL of tetrahydrofuran solvent is required for every 1 mmol of the reactant. The reaction time is 2 Hour, adopt sodium carbonate catalyzer, consumption is the 5mol% of diaminodiphenyl sulfone, and temperature of reaction is 40 ℃; 80 ℃ of normal pressure distillations after reaction finishes and remove impu...

Embodiment 3

[0047] (1) Dissolve m-phenylenediamine and 1,3-bis(chloromethyl)-1,1,3,3-tetramethyldisiloxane in DMF at a molar ratio of 2:1, and the amount of DMF is : 5mL of DMF solvent is required for every 1mmol of reactant, the reaction time is 1.5 hours, triethylamine catalyst is used, the dosage is 1mol% of m-phenylenediamine, and the reaction temperature is 100°C; after the reaction is completed, the solvent is distilled off at 200°C under normal pressure, etc. (2) dissolving m-phenylenediamine and trichloroethyl phosphate in DMF according to the molar ratio of 3:1, the amount of DMF is: 5mL of DMF solvent is needed for every 1mmol reactant, and the reaction time is 3 hours , adopt triethylamine catalyst, consumption is the 1mol% of m-phenylenediamine, and temperature of reaction is 80 ℃; 200 ℃ of normal pressure distillations after reaction finishes and removes impurities such as solvent, obtains B product; (3) (1) and ( 2) The medium product is mixed according to the mass ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com