Main-grid-free solar battery, preparation method and application thereof, and battery module and preparation method thereof

A technology of solar cells and battery components, applied in the field of solar cells, can solve the problems of high manufacturing cost, high technical cost, and complicated manufacturing process of solar cells without bus bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

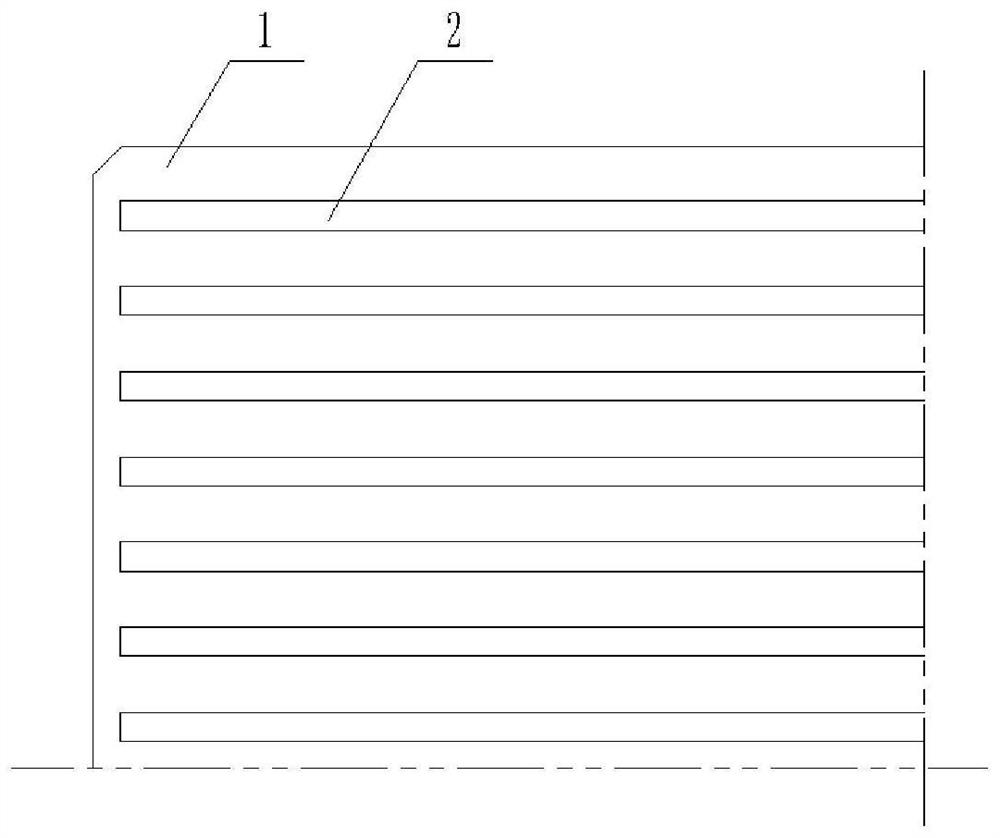

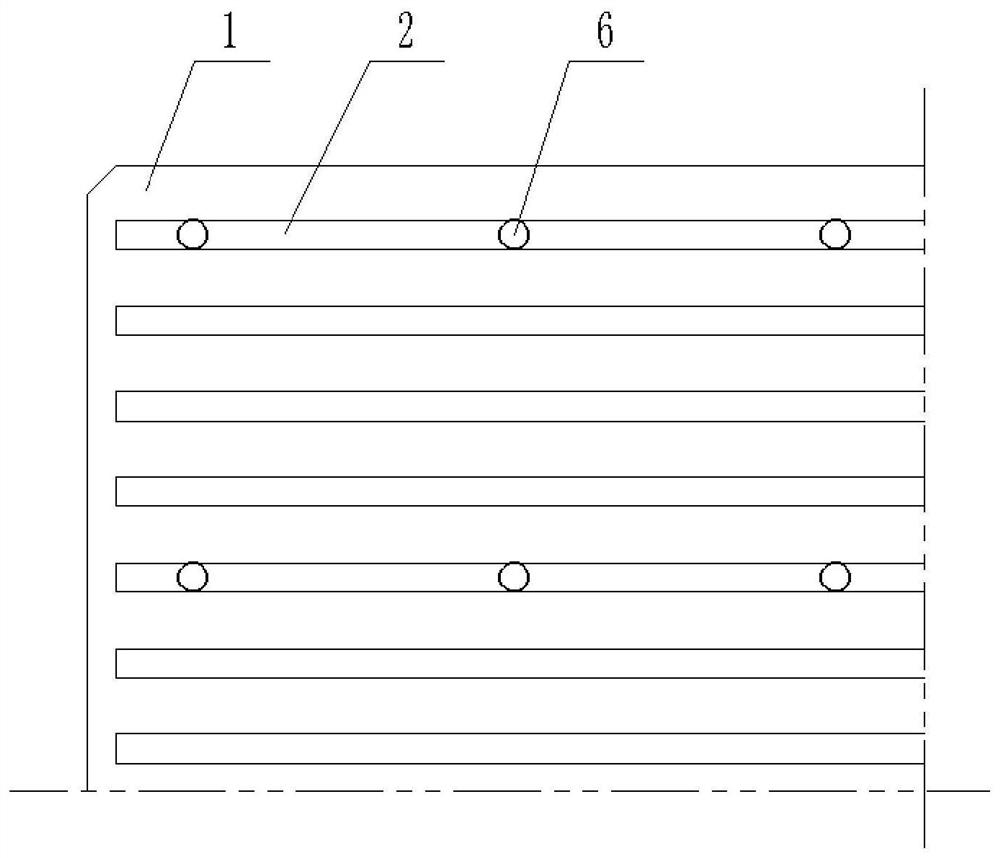

[0051] like Figure 1 to Figure 5 As shown, a busbar-free solar cell of the present invention includes a battery sheet 1 without a busbar and a plurality of upper and tinned metal wires 3 that do not intersect with each other and intersect each fine grid line 2 on the front side of the battery sheet 1 A plurality of solder paste pads 6 are distributed on the thin grid lines 2 on the front side of the battery sheet 1, and the tinned metal wire 3 passes through the solder paste pads 6 to connect each thin grid line 2 provided with the solder paste pads 6 Electrically connected in series in the arrangement direction of the fine grid lines.

[0052] The electrode pattern of the solar cell designed by the present invention only prints thin grid lines at the battery end, and cancels the main grid line; at the same time, the tinned metal wire used as the "main grid" is connected to the component end through the solder paste pad, so that the tinned metal wire Combines nicely with the...

Embodiment 2

[0056] This embodiment is based on the embodiment 1 to further describe the busbarless solar cell.

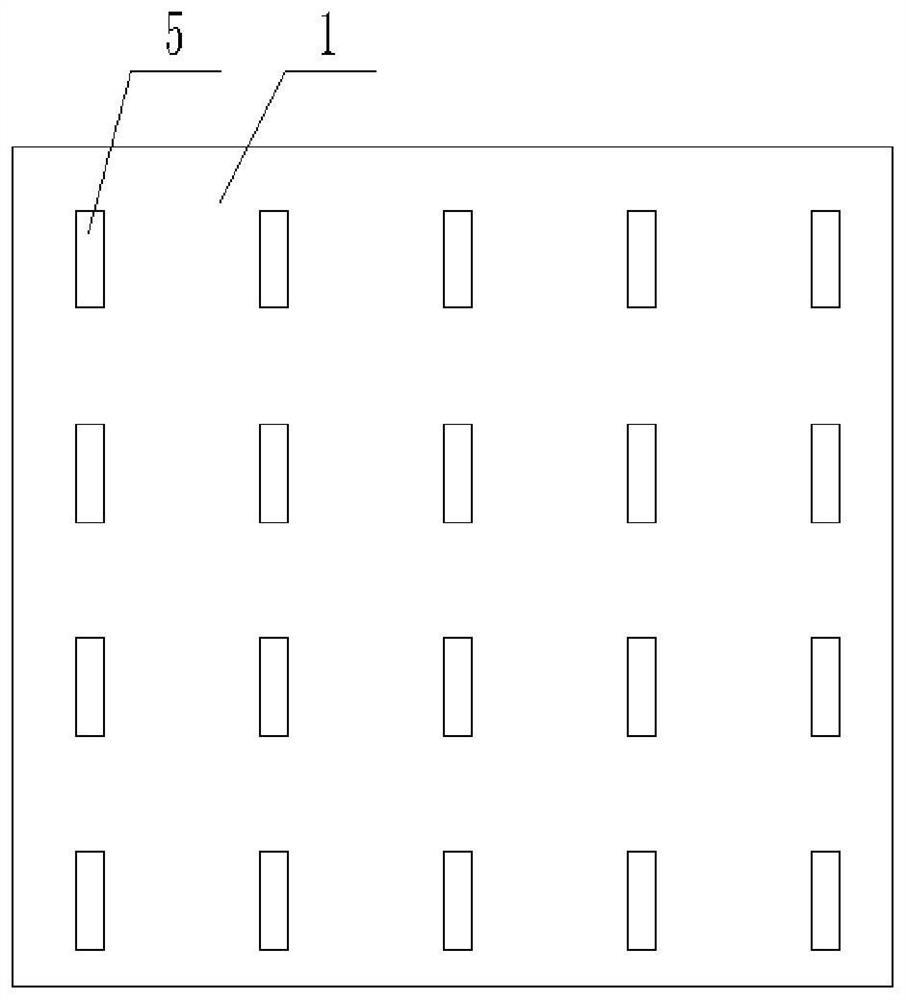

[0057] like Image 6 As shown, a busbar-free solar cell includes a battery sheet 1 without a busbar and a plurality of upper and tin-plated metal wires 3 that do not intersect each other and intersect each thin grid line 2 on the front side of the battery sheet 1. A plurality of solder paste pads 6 are distributed on the thin grid lines 2 on the front of the sheet 1, and the tinned metal wire 3 passes through the solder paste pads 6 to connect each thin grid line 2 provided with the solder paste pads 6 on the thin grid lines. Electrically connected in series in the direction of arrangement; multiple back electrodes of the battery sheet 1 are arranged in a matrix, and tinned metal wires having the same number as the vertical columns arranged in the matrix and not intersecting each other are arranged on the back of the battery sheet 1, The tinned metal wire connects the back ele...

Embodiment 3

[0063] A battery assembly, including a front layer material, an encapsulation material, a solar cell layer, an encapsulation material and a back layer material connected from top to bottom, the solar cell layer includes several solar cells arranged in sequence, and the solar cell is implemented In the solar cell in Example 1 or Example 2, among two adjacent solar cells, the tinned metal wire 3 on the front of one solar cell is electrically connected to the tinned metal wire 3 on the back of the other solar cell, so that the positive and negative electrodes are connected in series.

[0064] Further, among two adjacent solar cells, the tinned metal wire 3 on the front of one solar cell is electrically connected to the tinned metal wire 3 on the back of the other solar cell through the bus bar 4 .

[0065] The present invention uses solder paste pads to fuse tinned metal wires and thin grid wires, thereby realizing the interconnection welding of batteries without busbars, realizin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com