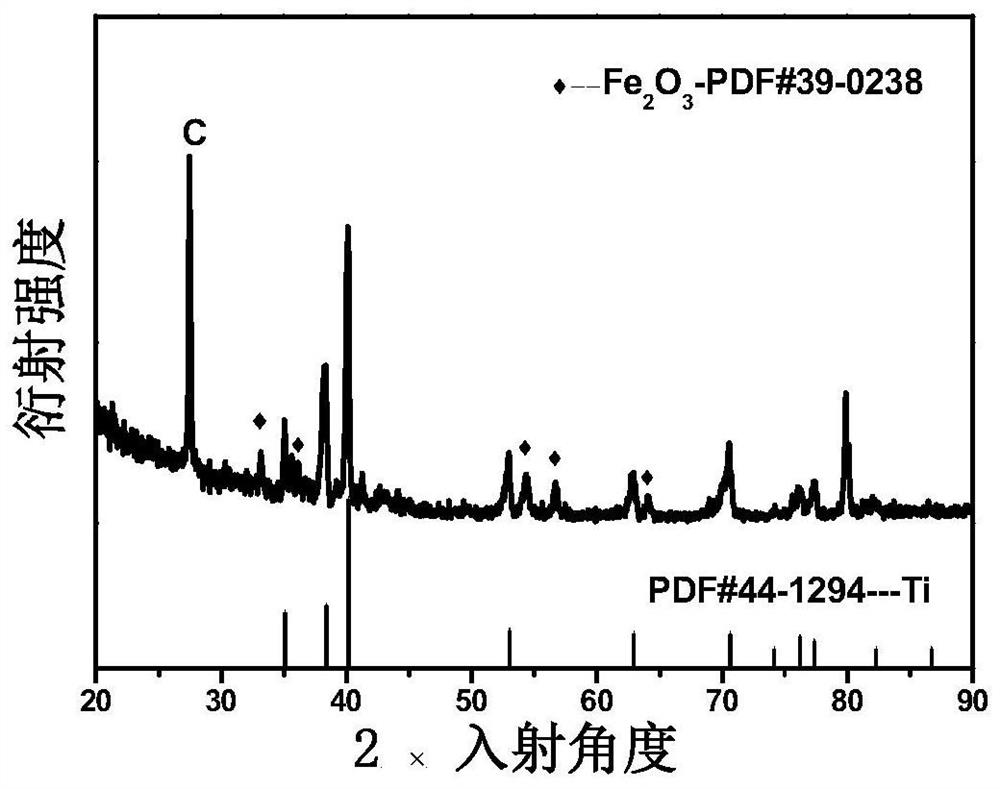

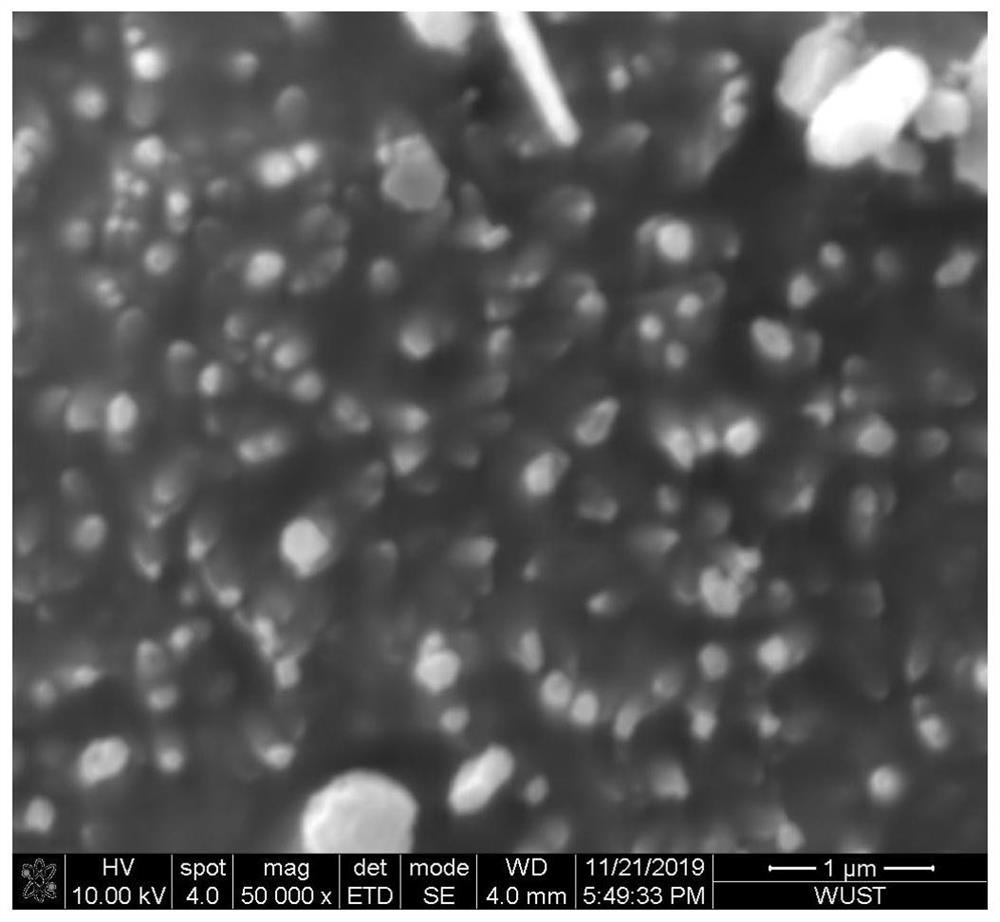

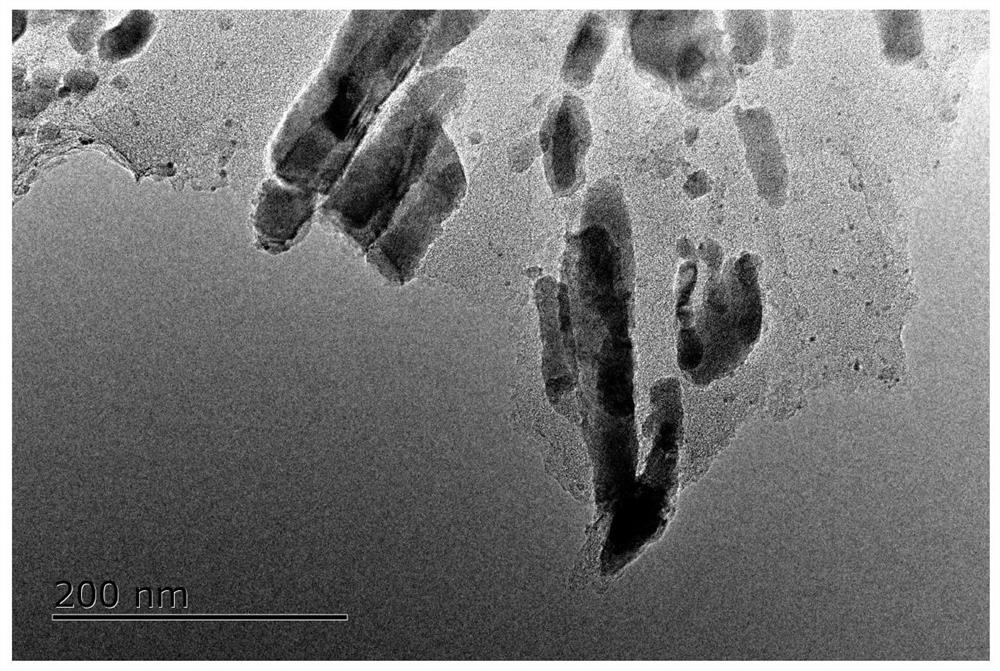

Carbon-coated iron oxide nanorod array material grown on foamed titanium substrate and its preparation method

A nanorod array and iron oxide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of rapid electrode capacity decay, environmental impact, poor rate performance, etc., to achieve Effects of shortened transportation path, less environmental pollution, and high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A carbon-coated iron oxide nanorod array material grown on a foamed titanium substrate and a preparation method thereof. The specific steps of the preparation method described in this embodiment are:

[0048] (1) by sodium sulfate: the mol ratio of ferric chloride hexahydrate is 1: 1 batching, mixes, obtains mixture; Then according to concentration, be 0.075mol / L that described mixture is dissolved in deionized water, stir under room temperature condition, A mixed solution was obtained.

[0049] (2) Ultrasonic cleaning of foamed titanium with detergent for 15 minutes, ultrasonic cleaning of ethanol for 20 minutes and ultrasonic cleaning of deionized water for 25 minutes, the foamed titanium after cleaning is immersed in the reaction kettle filled with the mixed solution, at 165 Hydrothermal reaction at ℃ for 6h, naturally cooled to room temperature; then washed with deionized water, dried at 80°C, annealed at 450°C for 2h under the protection of argon to obtain iron ox...

Embodiment 2

[0056] A carbon-coated iron oxide nanorod array material grown on a foamed titanium substrate and a preparation method thereof. The specific steps of the preparation method described in this embodiment are:

[0057] (1) by sodium sulfate: the molar ratio of ferric chloride hexahydrate is 1: 1 batching, mix, obtain mixture; Then be that 0.05mol / L is dissolved in deionized water by described mixture by concentration, stir under room temperature, A mixed solution was obtained.

[0058] (2) Ultrasonic cleaning of foamed titanium with detergent for 30 minutes, ultrasonic cleaning of ethanol for 15 minutes and ultrasonic cleaning of deionized water for 20 minutes, the foamed titanium after cleaning is immersed in the reaction kettle filled with the mixed solution, at 170 Hydrothermal reaction at ℃ for 5 hours, naturally cooled to room temperature; then washed with deionized water, dried at 60 ℃, annealed at 430 ℃ and under the protection of argon for 3 hours to obtain iron oxide na...

Embodiment 3

[0065] A carbon-coated iron oxide nanorod array material grown on a foamed titanium substrate. The specific steps of the preparation method described in this embodiment are:

[0066] (1) by sodium sulfate: the mol ratio of ferric chloride hexahydrate is 1: 1 batching, mixes, obtains mixture; Then according to concentration, be 0.06mol / L that said mixture is dissolved in deionized water, stir under room temperature, A mixed solution was obtained.

[0067] (2) Ultrasonic cleaning of foamed titanium with detergent for 20 minutes, ultrasonic cleaning of ethanol for 25 minutes and ultrasonic cleaning of deionized water for 30 minutes, the foamed titanium after cleaning is immersed in the reaction kettle filled with the mixed solution, at 160 Hydrothermal reaction at ℃ for 6h, naturally cooled to room temperature; then washed with deionized water, dried at 70°C, annealed at 460°C for 2h under the protection of argon to obtain iron oxide nanorods grown on foamed titanium substrates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com