TiO2 catalyst for catalytically eliminating benzene series in air and preparation method of TiO2 catalyst

A technology for catalysts and benzene series, which is applied in the field of TiO2 catalyst and its preparation to catalyze the elimination of benzene series in the air. It can solve the problems of irregular pore size distribution, limited catalytic performance, and underdeveloped pores, so as to reduce the cost of the catalyst and repeat the process. Good performance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

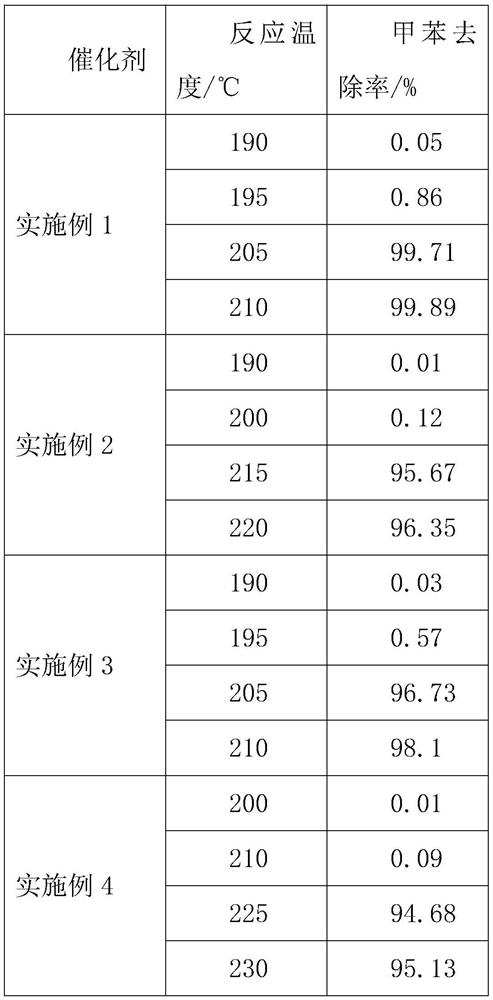

Embodiment 1

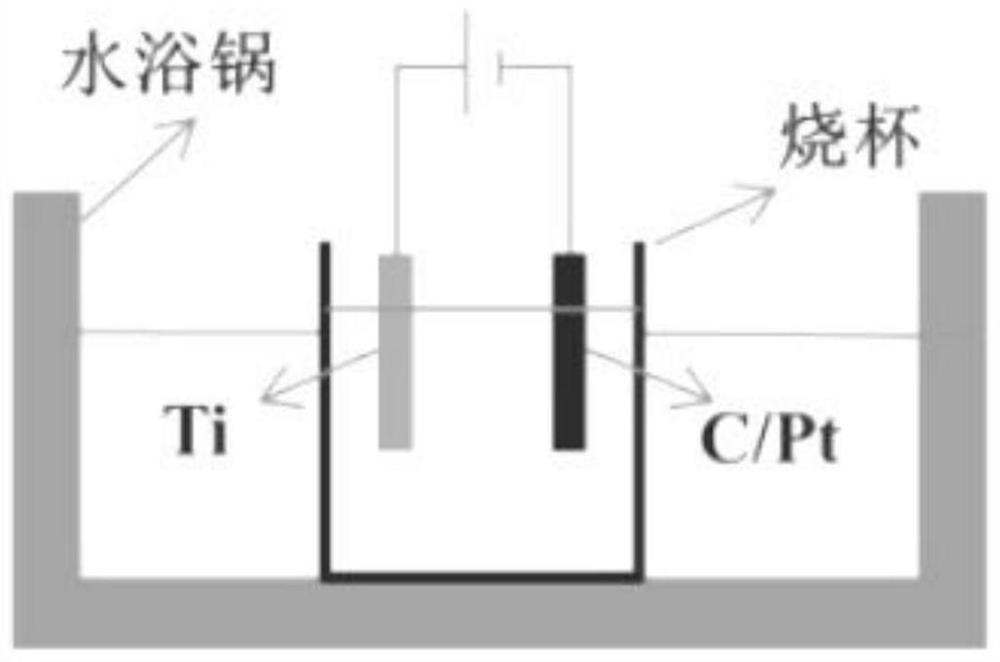

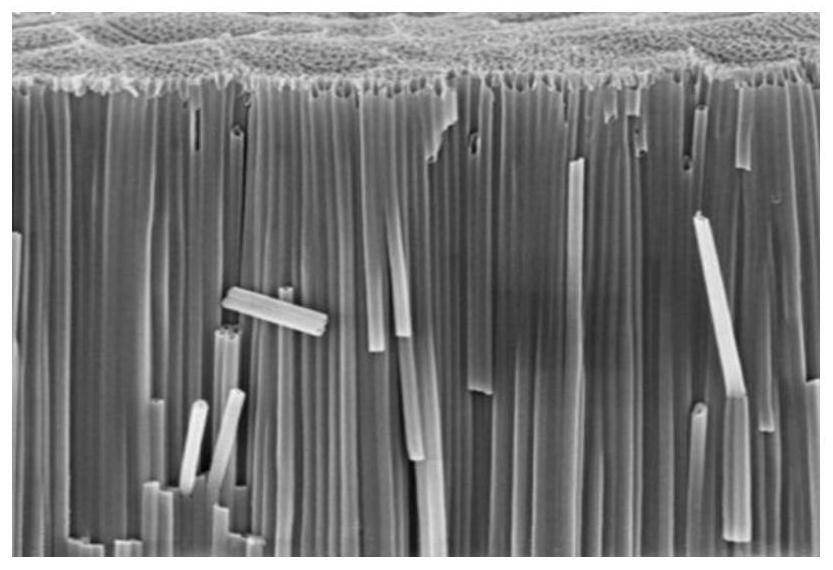

[0025] TiO in this example 2 The preparation method of catalyst comprises the following steps:

[0026] 1) Titanium sheet polishing: Cut the titanium sheet into rectangular strips of 6cm×1cm, and completely immerse in the pre-configured polishing solution (volume ratio V(HF):V(HNO 3 ):V(H 2 (O)=1:1:2) for about 15s, rinse with deionized water first, then soak in deionized water for 15min, dry the titanium piece for later use, and stick a waterproof tape on one end of the titanium piece to ensure the oxidation area 4cm 2 ;

[0027] 2) Primary oxidation: with titanium sheet as the anode and graphite as the cathode, the electrolyte composition is 0.5wt% NH 4 F and 2wt%H 2 Anodic oxidation was carried out in ethylene glycol solution of O, the oxidation current was 40mA, the oxidation time was 900s, and the oxidation temperature was 20°C;

[0028] 3) Ultrasonic stripping: put the oxidized sample in deionized water, and ultrasonic stripping for 15 minutes;

[0029] 4) Seconda...

Embodiment 2

[0033] Compared with Example 1, the difference is that the primary oxidation and secondary oxidation time are both 300 seconds, and other operating conditions are the same as in Example 1.

Embodiment 3

[0035] Compared with Example 1, the difference is that the primary oxidation and secondary oxidation time are both 600 seconds, and other operating conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com