Ester exchange type dynamic covalent polymer network material containing non-planar ring and preparation method of ester exchange type dynamic covalent polymer network material.

A non-planar, transesterification technology, applied in the field of sustainable thermosetting resin preparation, can solve the problems of complex preparation process and slow remodeling, and achieve the effect of simple preparation process, thermal maintenance, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] Specifically, as an aspect of the technical solution of the present invention, the preparation method of a transesterification type dynamic covalent polymer network material containing a non-planar ring comprises: making an epoxy monomer containing a non-planar ring, The homogeneous mixed reaction system of cyclic acid anhydrides and polyhydroxy compounds containing non-planar rings is pre-reacted, and then undergoes curing reaction to obtain transesterification-type dynamic covalent polymer network materials containing non-planar rings.

[0021] The reaction mechanism of the present invention is that: the preparation method of the non-planar ring-containing transesterification dynamic covalent polymer network proposed by the present invention introduces a non-planar ring structure, and through the conformational transformation of the non-planar ring, after mixing the three reaction raw materials evenly , the mixed system is pre-reacted. In the mixed system of the three,...

Embodiment 1

[0037]Mix diglycidyl hexahydrophthalate, hexahydrophthalic anhydride, and trimethylolpropane in a single-necked flask at a molar ratio of 1:2.5:0.83; place the mixed system in an oil bath at 90°C for a pre-reaction for 5 hours ; Pour the pre-reaction product into a polytetrafluoroethylene mold, put the mold into a vacuum oven, and evacuate it; the control system is cured under vacuum conditions, and the curing process is 120°C for 2h, 150°C for 2h, and 180°C for 2h ; After natural cooling, the solidified product is taken out from the oven to obtain a transparent light yellow film material (ie, the aforementioned transesterification-type dynamic covalent polymer network material containing non-planar rings).

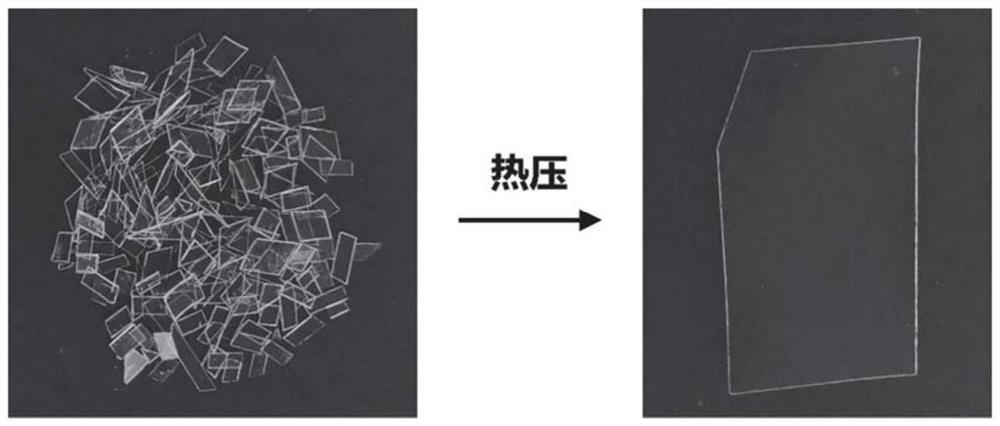

[0038] After the polymer network material prepared in this example is cut into pieces, it can be hot-pressed at 180°C for 1 hour with a flat vulcanizer, and the complete material can be obtained again. Please refer to figure 1 shown. In addition, the material had a glass...

Embodiment 2

[0040] Mix diglycidyl methyl hexahydrophthalate, hexahydrophthalic anhydride, and pentaerythritol in a single-necked flask at a molar ratio of 1:2.5:0.625, add an appropriate amount of ethyl acetate to the flask to clarify the system; put the mixed system on Pre-react in an oil bath at 80°C for 5 hours, and volatilize the solvent while reacting; pour the pre-reaction product into a polytetrafluoroethylene mold, put the mold into a vacuum oven, and vacuum; control the system to cure under vacuum conditions, The process is to react at 120°C for 2 hours, at 150°C for 2 hours, and at 180°C for 2 hours; after natural cooling, take the solidified product out of the oven to obtain a transparent light yellow film material.

[0041] After the polymer network material prepared in this example is cut into pieces, it can be hot-pressed at 180°C for 1 hour with a flat vulcanizer, and the complete material can be obtained again. Please refer to figure 1 shown. In addition, the material had...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com