Fiber surface treatment method

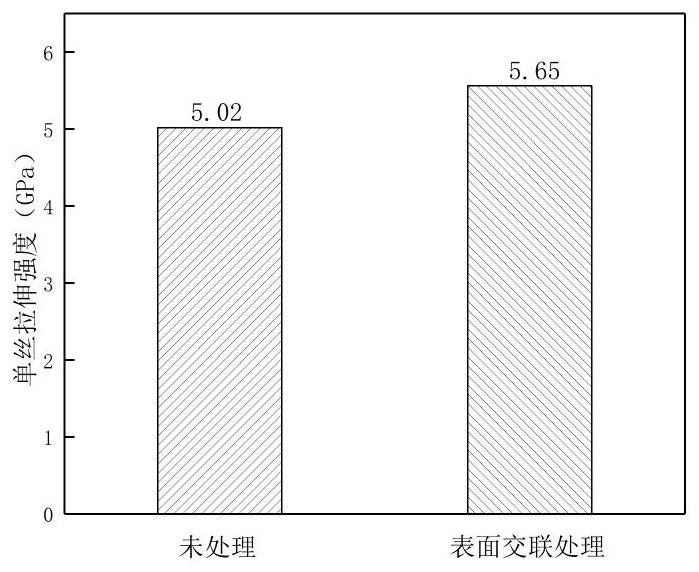

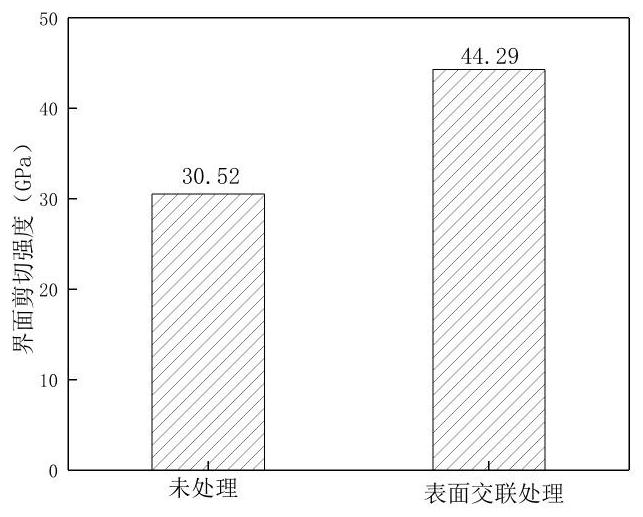

A treatment method and fiber surface technology, which is applied in fiber treatment, fiber type, textiles and papermaking, etc., can solve the problems of poor bonding performance between fiber and resin matrix, achieve large-scale production, good application prospects, and improve mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

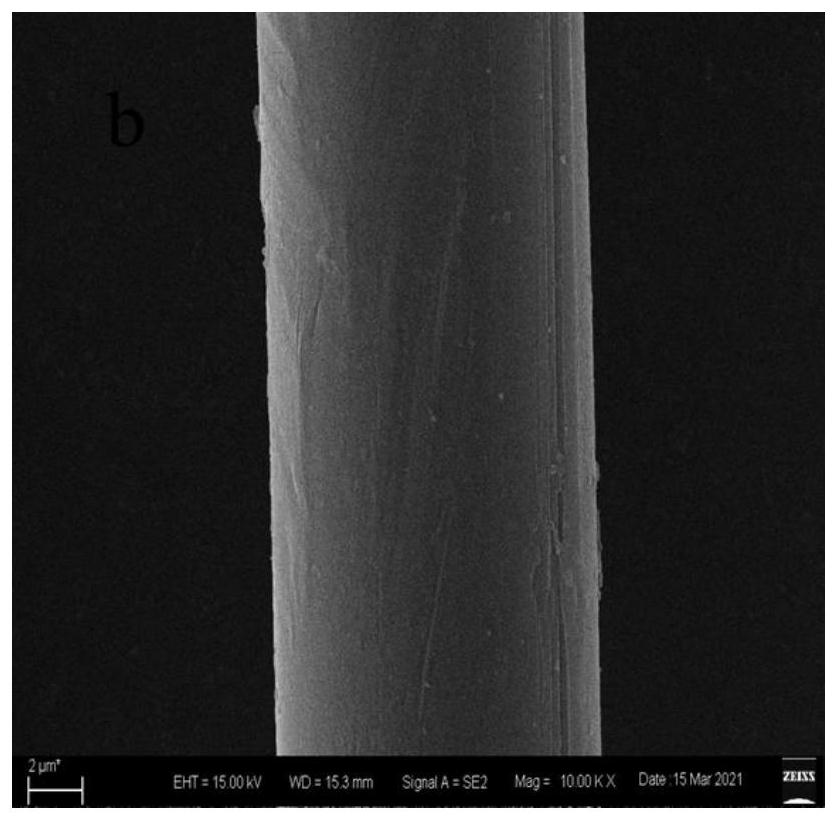

[0023] Specific embodiment one: what this embodiment describes is a kind of fiber surface treatment method, described method comprises the following steps:

[0024] Step 1: Soak the fiber in a solution of 0.1% to 15% small molecule surfactant for 1 to 120 minutes. The small molecule surfactant can form a chemical bond with the inert surface of the fiber to improve the adhesion of the fiber surface to obtain activated fiber 1;

[0025] Step 2: immerse the activated fiber 1 in a polymer solution with a concentration of 1% to 40% for 1 min to 60 min, take it out after ultrasonic treatment, and obtain the activated fiber 2 after the surface is dried;

[0026] Step 3: immerse the activated fiber 2 in a 0.1% to 60% cross-linking agent solution to perform chemical cross-linking, so that the polymer forms a three-dimensional cross-linked network structure on the surface of the fiber to obtain the activated fiber 3;

[0027] Step 4: immerse the activated fiber 3 in a 0.1%-15% resin sol...

specific Embodiment approach 2

[0030] Specific embodiment two: a kind of fiber surface treatment method described in specific embodiment one, in step one, described fiber is PBO fiber, aramid fiber, carbon fiber, polyester fiber, glass fiber, nylon 66, polyphenylene sulfide One of fiber, basalt fiber or ultra-high molecular weight polyethylene fiber.

specific Embodiment approach 3

[0031] Specific embodiment three: a kind of fiber surface treatment method described in specific embodiment one, in step one, described small molecule surfactant is silane coupling agent, oxalyl chloride, adipoyl chloride, butenedioyl chloride, acrylic acid One or more mixtures of diacid chloride, glutaraldehyde or adipaldehyde. These small molecule surfactants can activate the fiber surface, increase the active groups on the fiber surface, and facilitate the compounding of the fiber and the polymer network.

[0032] Specific embodiment four: a fiber surface treatment method described in specific embodiment three, the silane coupling agent is KH-550, KH-560, KH-570, KH-151, KH-171 or KH-792 One or more combinations of . These silane coupling agents can form amine groups on the fiber surface and increase the fiber surface energy.

[0033] Specific embodiment five: a kind of fiber surface treatment method described in specific embodiment one, in step two, described polymer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com