Ultrathin polymer electrolyte membrane based on porous polyimide and preparation method thereof

A technology of polyimide membrane and electrolyte membrane, which is applied in the direction of solid electrolyte, non-aqueous electrolyte, non-aqueous electrolyte battery, etc., can solve the problems of reducing mechanical strength, increasing membrane rupture, safety accidents, etc., and achieves low interface impedance, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

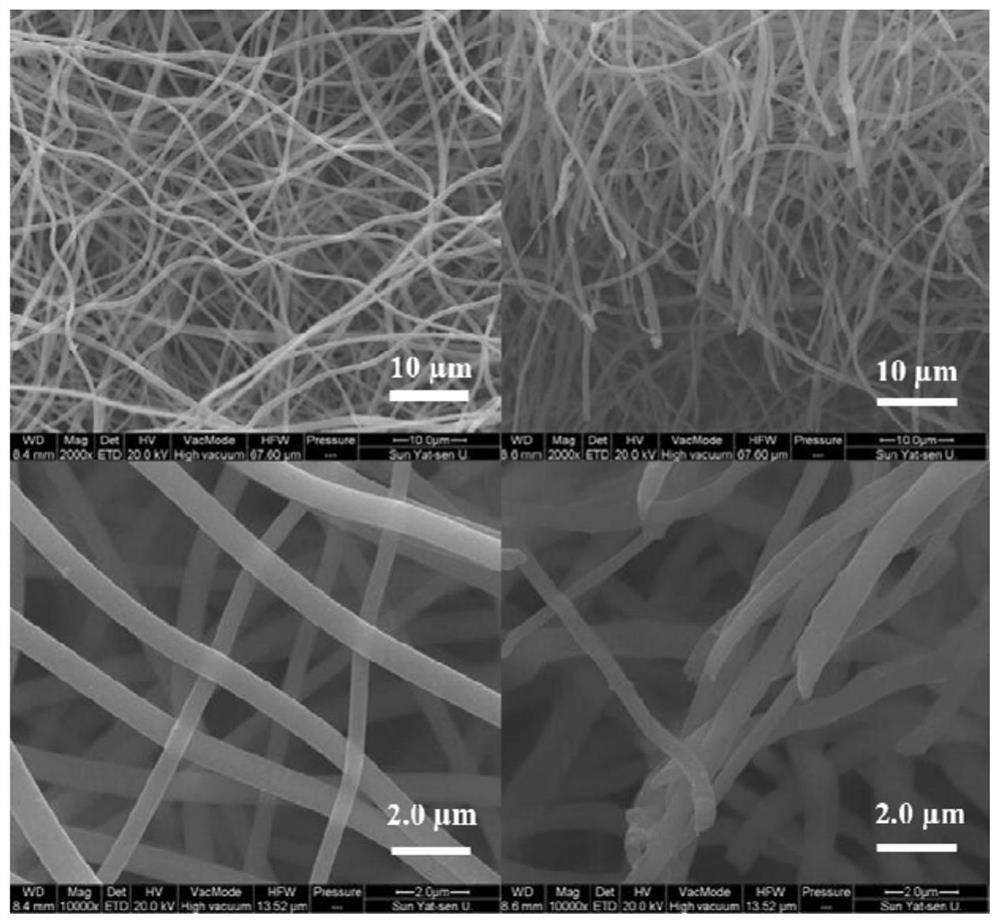

Image

Examples

Embodiment 1

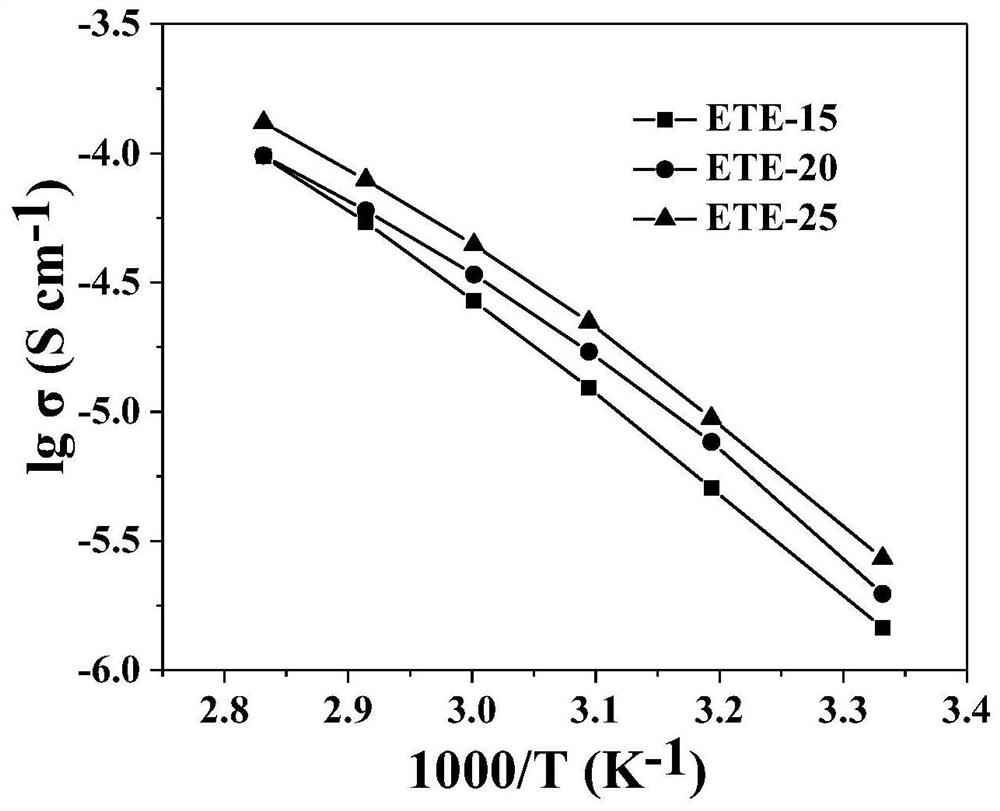

[0035] Embodiment 1: the preparation of ultra-thin polymer electrolyte membrane (SPE-1)

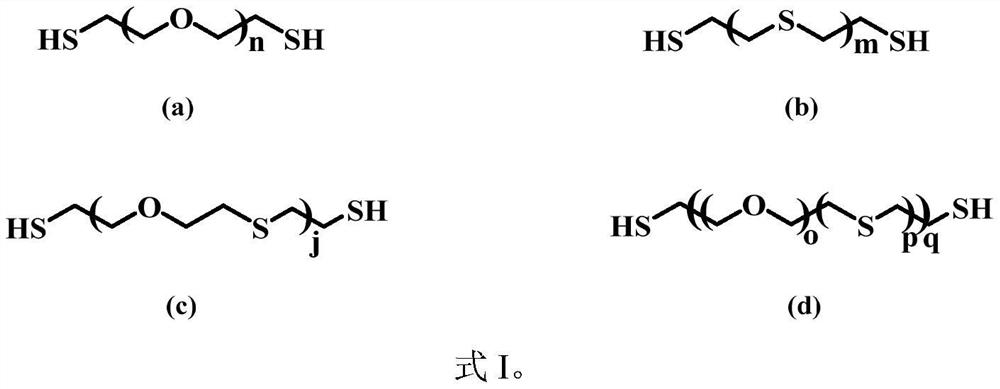

[0036] 1,2-Ethanedithiol (EDT) and diethylene glycol divinyl ether (DGDE) were the reactive monomers, and 2,2-dimethoxy-2-phenylacetophenone (DMPA) was the photoinitiated Lithium bistrifluorosulfonyl imide (LiTFSI, formula IV (a)) is a small molecule lithium salt, pentaerythritol tetraacrylate (PET4A, formula II (a)) is a crosslinking agent, and anhydrous tetrahydrofuran (THF) is solvent.

[0037] The following operations were all carried out in a glove box under an argon atmosphere. The reaction is divided into two steps. The first step: add EDT and DGDE to a 20mL small glass bottle, then add DMPA, stir it in the dark to dissolve it completely, and initiate the reaction under 365nm ultraviolet light to prepare a sulfhydryl-terminated linear Ion-conducting polymer (formula I(d)); the second step: add LiTFSI, PET4A, THF and DMPA to the above product, stir in the dark to dissolve complete...

Embodiment 2

[0044] Embodiment 2: the preparation of ultra-thin polymer electrolyte membrane (SPE-2)

[0045]1,2-Ethanedithiol (EDT) and diethylene glycol divinyl ether (DGDE) were the reactive monomers, and 2,2-dimethoxy-2-phenylacetophenone (DMPA) was the photoinitiated Lithium perchlorate (LiClO4, formula IV (i)) is a small molecule lithium salt, hexaeugenol cyclotriphosphazene (HECTP, formula III (a)) is a crosslinking agent, and anhydrous tetrahydrofuran (THF) is a solvent .

[0046] Except that the small molecule lithium salt and the cross-linking agent were changed, the dosage and operation steps of each reagent were the same as in Example 1.

[0047] In the linear ion-conducting polymer, q is preferably 10-25.

[0048] The molar ratio of the linear ion-conducting polymer to HECTP is 3:1.

[0049] The mass proportion of the lithium salt in the ultra-thin polymer electrolyte membrane is 25%.

[0050] The added amount of DMPA is 3%.

[0051] The added amount of the solvent THF is...

Embodiment 3

[0053] Embodiment 3: the preparation of ultra-thin polymer electrolyte membrane (SPE-3)

[0054] 1,2-Ethanedithiol (EDT) and diethylene glycol divinyl ether (DGDE) were the reactive monomers, and 2,2-dimethoxy-2-phenylacetophenone (DMPA) was the photoinitiated Agent, lithium bistrifluorosulfonyl imide (LiTFSI, formula IV (a)) is a small molecule lithium salt, hexaeugenol cyclotriphosphazene (HECTP, formula III (a)) is a crosslinking agent, anhydrous tetrahydrofuran ( THF) as solvent.

[0055] Except that the cross-linking agent was changed, the dosage and operation steps of each reagent were the same as in Example 1.

[0056] In the linear ion-conducting polymer, q is preferably 10-25.

[0057] The molar ratio of the linear ion-conducting polymer to HECTP is 3:1.

[0058] The mass proportion of the lithium salt in the ultra-thin polymer electrolyte membrane is 30%.

[0059] The added amount of DMPA is 5%.

[0060] The added amount of the solvent THF is 30% of the total ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com