Metal ditelluride nanosheet and preparation method thereof

A technology of telluride and nanosheets, which is applied in the field of nanomaterials, can solve the problems of easily damaged material crystallinity and metering ratio, the inability to obtain two-dimensional structures, and low yield of nanosheets, and achieve excellent electrical properties, process controllable, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing ditelluride nanosheets, comprising: S1) under high pressure conditions, mixing and reacting metal ditelluride crystals, alkali metal salts and aprotic solvents to obtain intermediates inserted with alkali metal ions; S2) Exfoliating the intermediate intercalated with alkali metal ions in a protic solvent to obtain ditelluride nanosheets.

[0036] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0037]Wherein, the metal ditelluride crystal is preferably a metal ditelluride layered crystal, and more preferably the metal ditelluride crystal is a graphene-like layered crystal; the metal ditelluride crystal is preferably a group IVB transition metal ditelluride One or more of compound crystals, VB group transition metal ditelluride crystals and VIB group transition metal ditelluride crystals, more preferably TiTe 2 、ZrTe 2 , NbTe 2 、TaTe 2 、MoTe 2 wit...

Embodiment 1

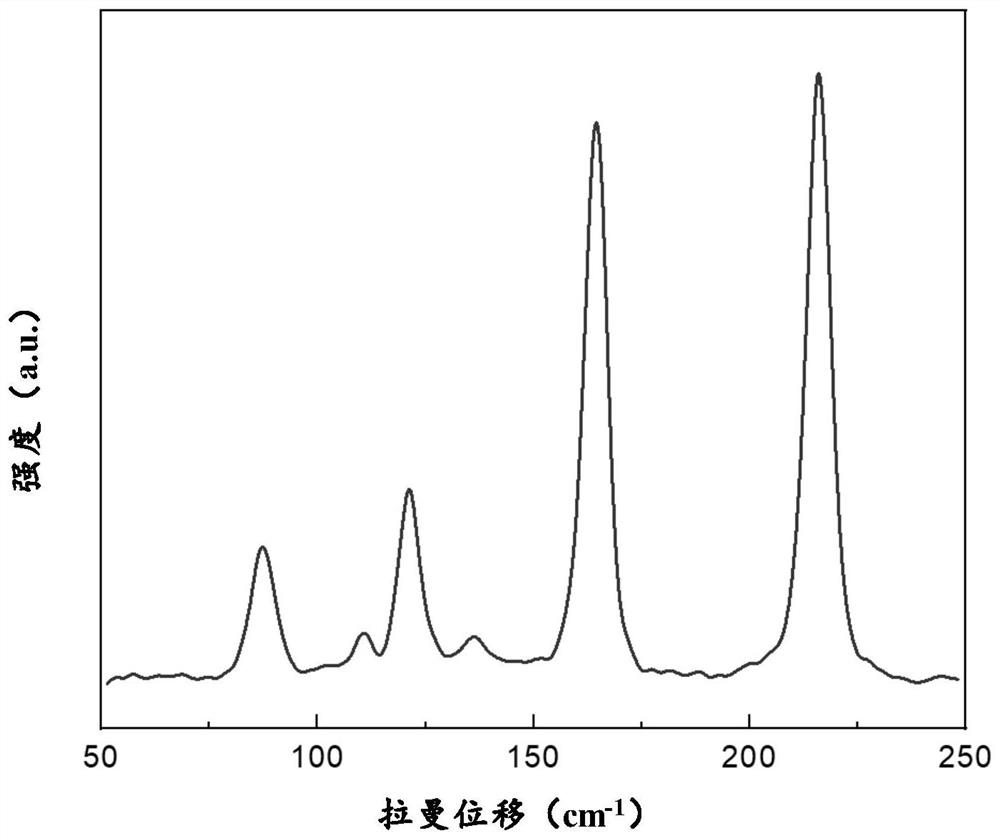

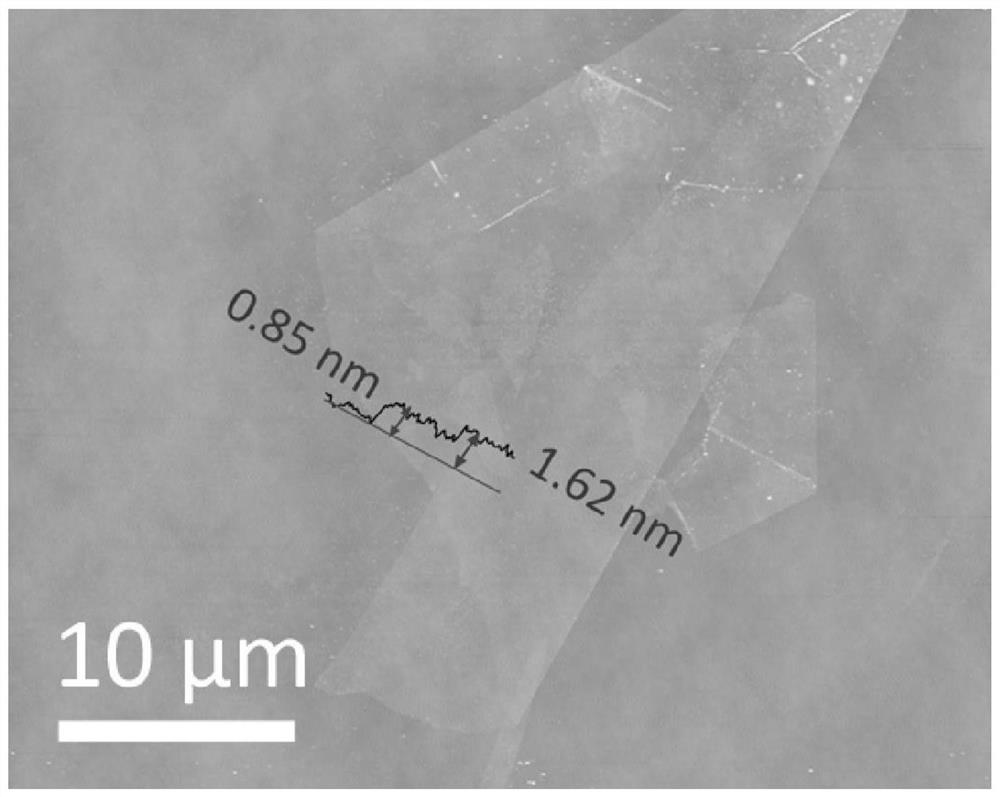

[0054] Large size single layer WTe 2 Exfoliation Preparation of Nanosheets

[0055] Put metal W, Te element and bromine element with a molar ratio of 1:2 into a quartz tube with a diameter of 1 cm and a length of 20 cm, and seal it after vacuumizing; the ratio of the amount of bromine element added to the metal to Te element substance is 5 mg: 1ml; place the sealed quartz tube in a muffle furnace at 900°C for 200 hours at a high temperature, and then naturally cool to room temperature to obtain WTe 2 single chip.

[0056] Add 100mg WTe to a 200ml sealable reactor 2 Single wafer and 40ml n-hexane, then add 3ml butyllithium n-hexane solution (25%), seal and react for 5 hours under low temperature (wherein the temperature is 60°C, pressure is 1.0MPa), take out the precipitated sample, you can get the plug layer intermediate; then put the intercalation intermediate in deionized water, and vibrate rapidly for 5s (vibration speed is not required) to obtain a well-dispersed large-...

Embodiment 2

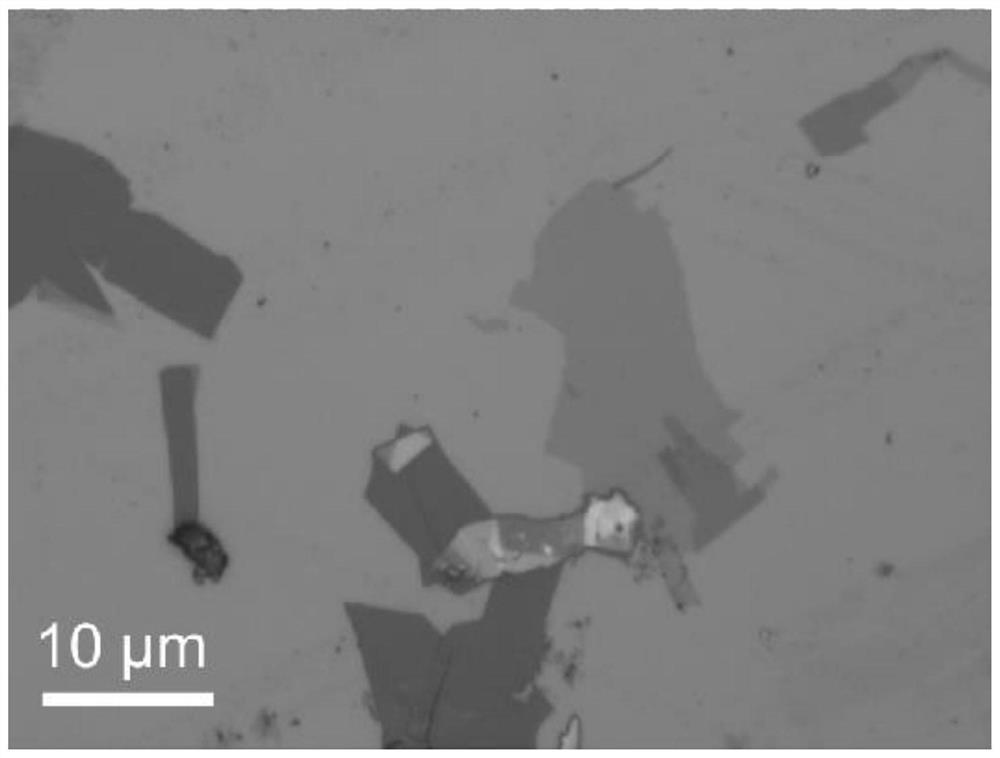

[0066] Large size single layer MoTe 2 Exfoliation Preparation of Nanosheets

[0067] Put metal Mo and Te elemental substance and bromine elemental substance with a molar ratio of 1:2 into a quartz tube with a diameter of 1 cm and a length of 20 cm, and seal it after vacuuming; the ratio of the amount of bromine elemental substance added to the volume of the quartz tube is 5mg: 1ml ; Place the sealed quartz tube in a muffle furnace at 950°C for 240 hours at high temperature, and cool it down to room temperature naturally to get MoTe 2 single chip.

[0068] Add 50mg MoTe to a 200ml sealable reactor 2 Single chip and 40ml of n-hexane, then add 3ml of butyllithium n-hexane solution (25%), and react for 5 hours under the conditions of sealed room temperature (wherein the temperature is 90°C and the pressure is 1.5MPa), and the precipitated sample is taken out to obtain the inserted layer intermediate; then put the intercalation intermediate in water and vibrate rapidly for 5s (t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com