Application of K2Mn2 (MoO4) 3 in negative electrode of lithium ion battery

A lithium-ion battery and negative electrode technology, which is applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as poor cycle stability, limit the practical application of materials, and make preparations difficult, and achieve high specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1K 2 mn 2 (MoO 4 ) 3 High-temperature solid-phase preparation of negative electrode materials

[0038] 0.01mol of K 2 CO 3, 0.02mol of MnO and 0.03mol of MoO 3 Put it in an agate mortar and grind for half an hour. Transfer to a crucible and place the crucible in the muffle furnace. The furnace was raised to 300°C at a heating rate of 5°C / min, kept for 5 hours, and finally cooled to room temperature at a rate of 20°C / min. The synthesized material is taken out, ground into powder and transferred again to a crucible and placed in a muffle furnace. The furnace was raised to 800°C at a heating rate of 5°C / min, kept for 20 hours, and finally cooled to room temperature at a rate of 20°C / min. The obtained product is taken out of the grinding component to obtain K 2 mn 2 (MoO 4 ) 3 compound.

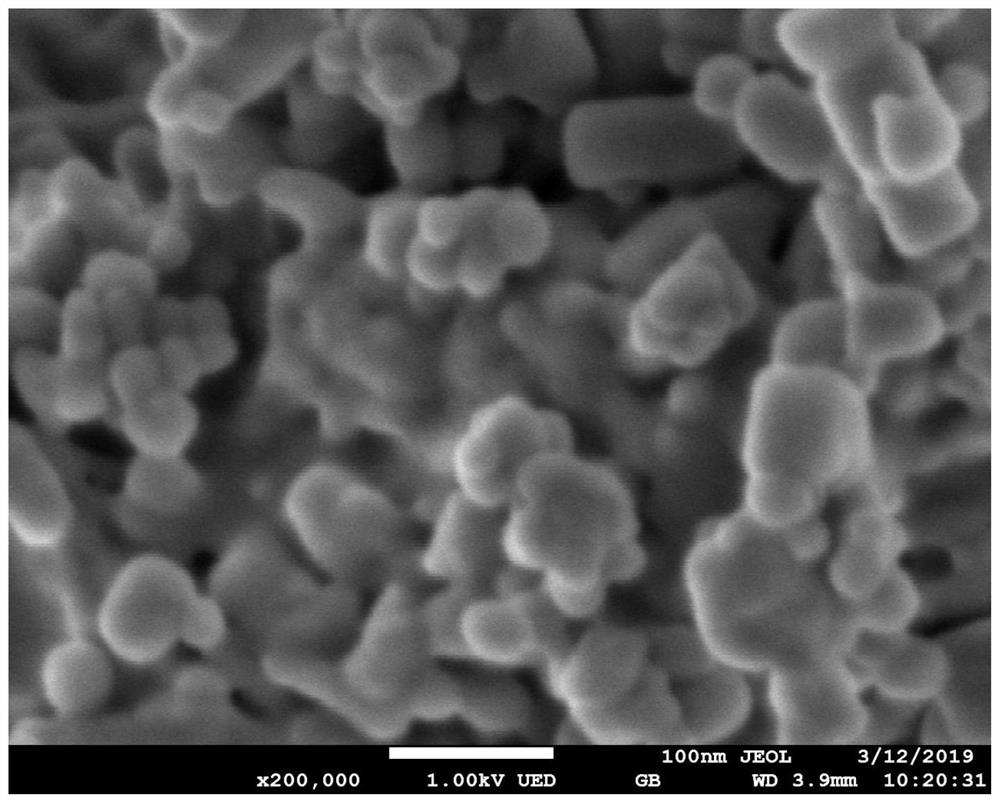

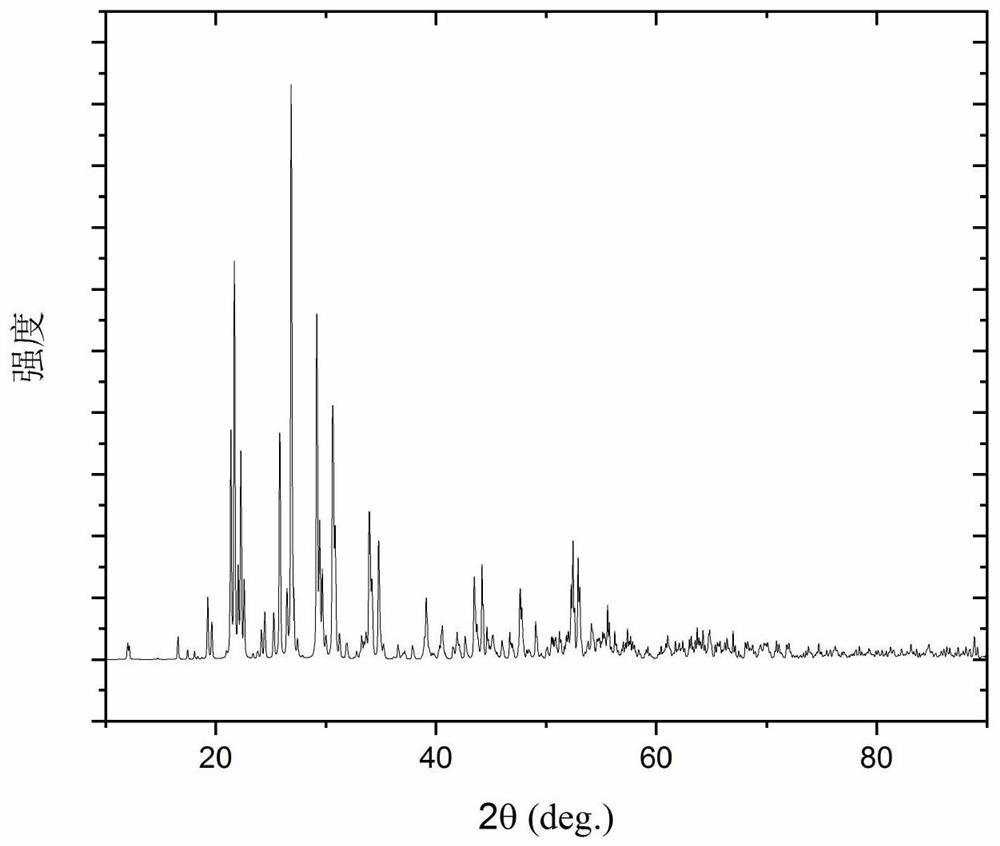

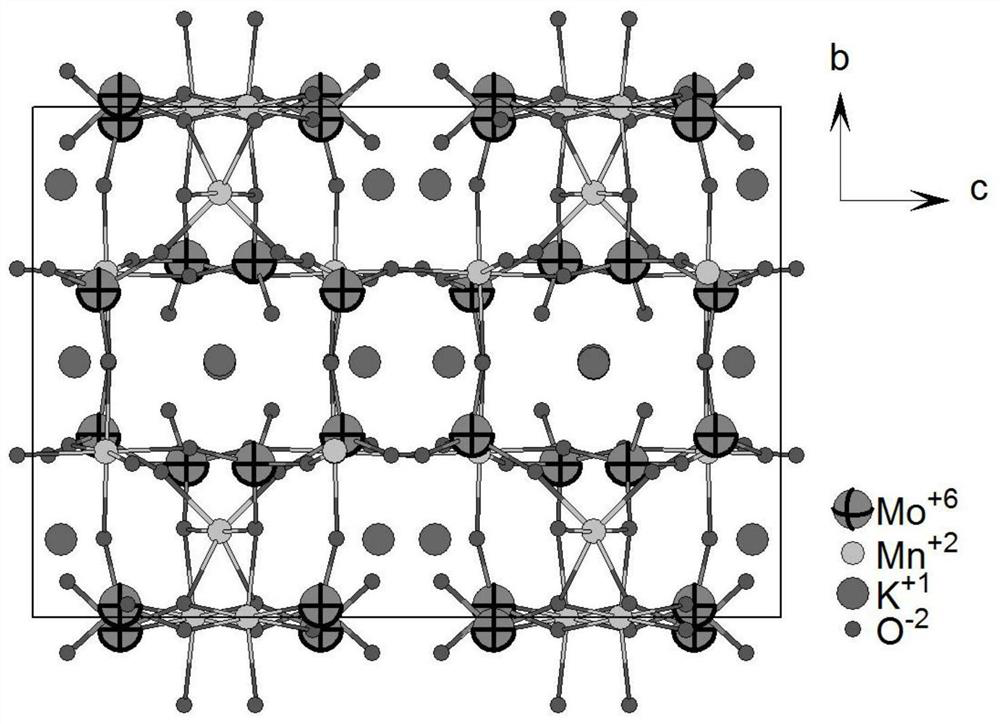

[0039] Such as figure 1 As shown, it is a gray-green powder with a tap density of 2.0g / cm 3 , melting point 840°C. Its X-ray diffraction pattern is as figure 2 A...

Embodiment 2

[0040] Example 2K 2 mn 2 (MoO 4 ) 3 Sol-gel Preparation of Anode Materials

[0041] Dissolve 0.03mol of oxalic acid in a beaker filled with 100ml of deionized water, then add 0.02mol of Mn(NO 3 ) 2 , Stir in a constant temperature water bath at 70-80°C until it turns into a green solution, then add 0.03mol of MoO 3 , 0.01mol of K 2 CO 3 , continue stirring to form a sol. Place the sol in an oven at 80°C and bake for about 10 hours to obtain a green fluffy precursor. Grind the precursor into powder and place it in a crucible, and put the crucible in a muffle furnace. The furnace was raised to 300°C at a heating rate of 5°C / min, kept for 5 hours, and finally cooled to room temperature at a rate of 20°C / min. The synthesized material is taken out, ground into powder and transferred again to a crucible and placed in a muffle furnace. The furnace was raised to 800°C at a heating rate of 5°C / min, kept for 20 hours, and finally cooled to room temperature at a rate of 20°C / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap